Istruction Manual for Operation and Maintenance SPX-960:

To disassemble the side boom (Fig. 19) refer to section «4.7 Installation of boom and blocks».

- Side boom 28’ ............................................................................................................................ 2450 Kg

- N. 2 counterweight leaf packs: .................................................................................4670 Kg + 6670 Kg

- A-frame: ........................................................................................................................................ 550 Kg

- Steps .............................................................................................................................................. 32 Kg

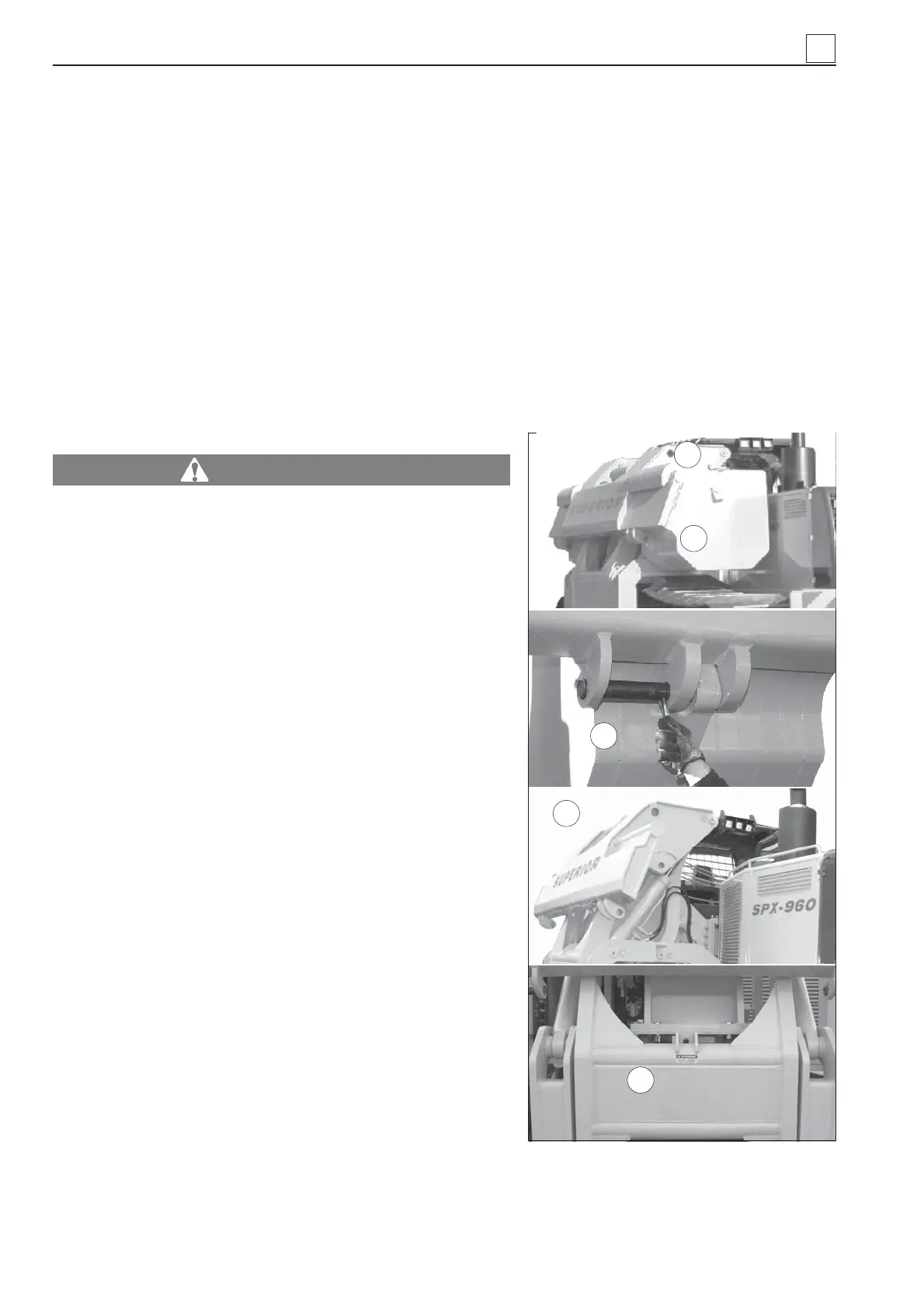

To disassemble the counterweight leaf packs (#1 at the front and #1 at the back) having a screw and pin

lock, undo the two large screws (1 in Fig. 18, front and back) and remove the two pins (2 in Fig. 18, front

and back).

Move the load-bearing frame as far out as to be able to lift one pack of leaves at a time easily and safe-

ly.

To disassemble the counterweight leaf packs (#1 at the front and #1 at the back) having a bolt lock, undo

the two bolts (3 in Fig. 18, front and back).

Move the load-bearing frame as far out as to be able to lift one pack of leaves at a time easily and safe-

ly.

WARNING

Transport the machine only after the counterweight has

been placed in vertical position and the frame has been

locked using the supplied safety bolt (4 in Fig. 18).

Before loading operations, make sure that the vehicle is

qualifi ed for this type of transportation and it has the correct

dimensions and capacity to bear the machine weight. This

information is also useful to check whether the machine can

be transported in narrow or low places.

The machine has a permanent integral hydrostatic drive and

cannot be towed with the engine off. To move the machine,

drive it from the control station.

The platform the machine is meant to be loaded onto must be

perfectly fl at. This will prevent the load from moving. Loading/

unloading ramps must not exceed a max. tilt of 15°.

• Check that the ground in the loading area is compact, fl at

and dry.

• Check that the ramps and support surfaces are not dama-

ged: they must not present weak points, missing edges or

excessive wear. If these surfaces prove unsafe, weak or

instable, do not load the machine. Make sure that the loa-

ding equipment and transport vehicle are in good condition

and have the proper capacity for loading operations.

• Engage the trailer brake and put blocks under the wheels

so as to stop it from moving. Align the ramps with the center

of both the trailer and the machine (Fig. 17).

• Make sure that both ramps are at the same height. The

max. tilt of the ramps must be 15°. Position the ramps so

that they coincide with the center of the tracks.

• Remove any mud from the undercarriage so that the ma-

chine does not slip sideways on the ramps. Also remove

any traces of water, snow, ice, grease, oil, etc. from the

ramps

3

Fig. 18 - Counterweight leaves

1) Counterweight leaf mounting screw - 2) Pins

- 3) Counterweight leaf mounting lock 4)

Counterweight without leaves 5) Safety bolt

4

5

3

1

2

3-4

MACHINE TRANSPORTATION

Loading...

Loading...