Istruction Manual for Operation and Maintenance SPX-960:

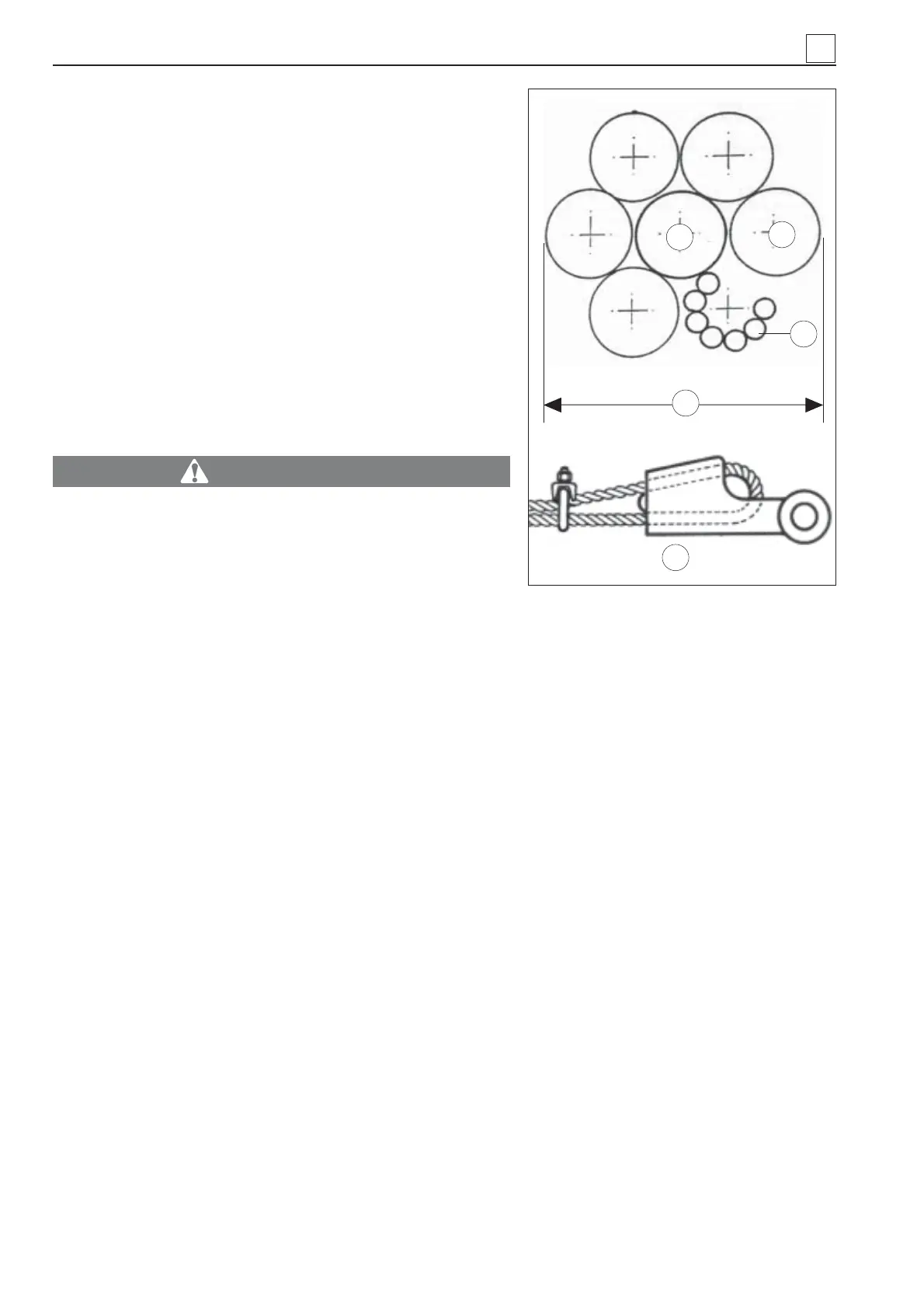

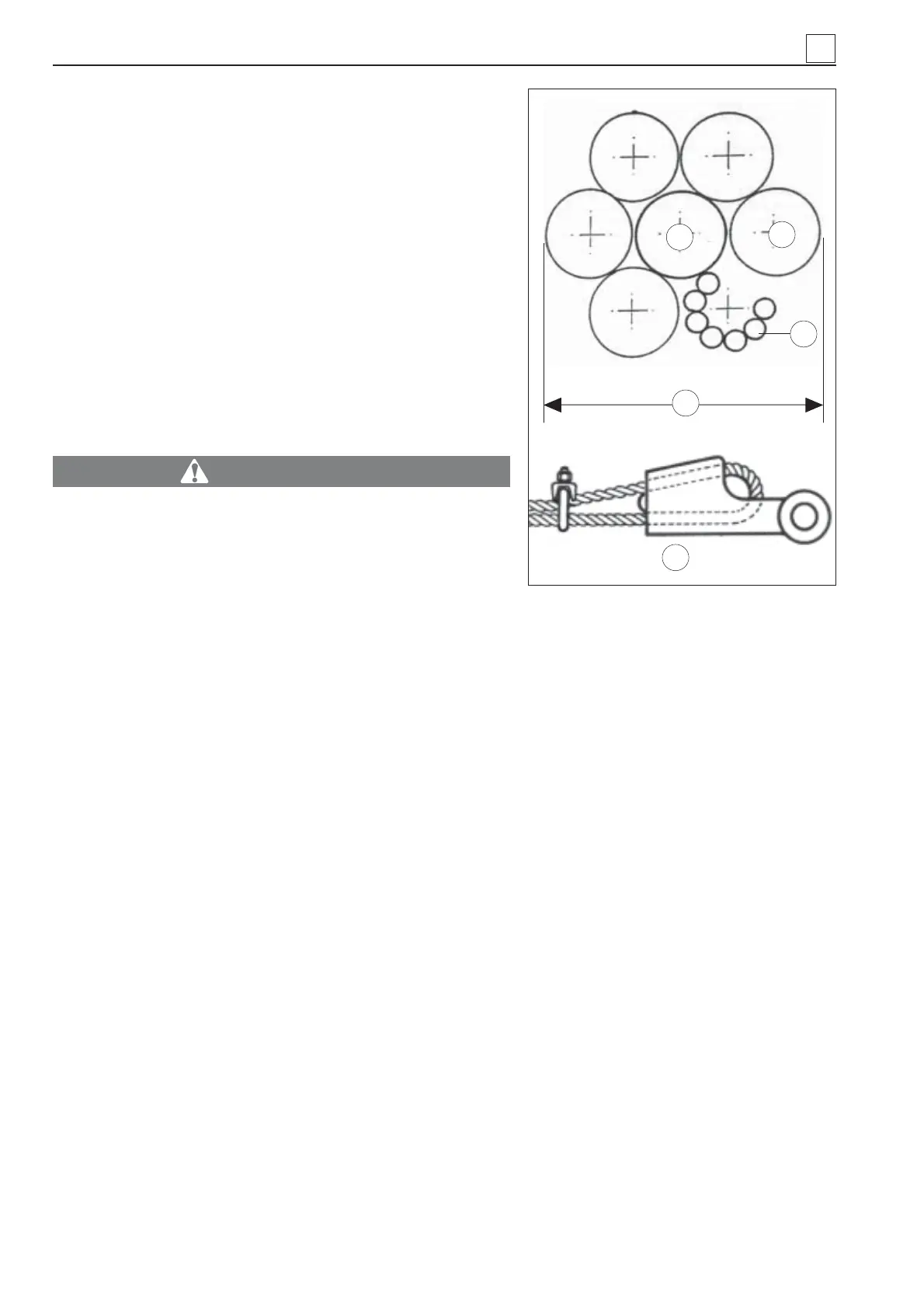

4.9.3 WIRE ROPE INSPECTION

The wire ropes must be kept under constant control for

wear. Regarding wire ropes refer to section 5.2 in Chapter

5 “Maintenance”.

The wire rope supervisor and tester must be qualifi ed to under-

stand the causes of possible breakage or damage to the rope:

he must be able to understand if the rope is in good operating

condition or if it needs to be replaced. (Fig. 51).

Small grooves cause wire rope deformations and excessive

contact between the rope elements (strands and core): this

may jeopardize wire rope performance and duration. The wire

rope duration is also affected

by groove wear. For instance, if the groove is excessively sco-

red or deformed, the wire rope is more likely to get worn.

DANGER

The wire rope is wound on parts which are specifi cally

sized according to the rope diameter. For this reason, it

is not recommended (due to more rapid wear) and it is

dangerous to use different wire rope diameters from those

indicated by the manufacturer.

Fig. 51

1) Wire rope core. - 2) Wire rope strand. - 3)

Wire rope. - 4) Wire rope diameter. 5) Wire

rope terminal clamp.

1

2

3

4

5

4

4-34

MACHINE OPERATION

Loading...

Loading...