IntelliShot & FlexoShot: Operations Manual Page 27

CLEANING THE DISPENSER

The dispenser and its components (e.g., valve), product cases, product case inserts, ramp, and

refillable tanks must be washed and sanitized regularly.

• Do not use any abrasive material or cleaners on the dispenser.

• Dispenser must not be cleaned by water jet.

• Do not spray any liquid or cleaners in or around the valve area. Liquid could damage electrical

components behind the valve.

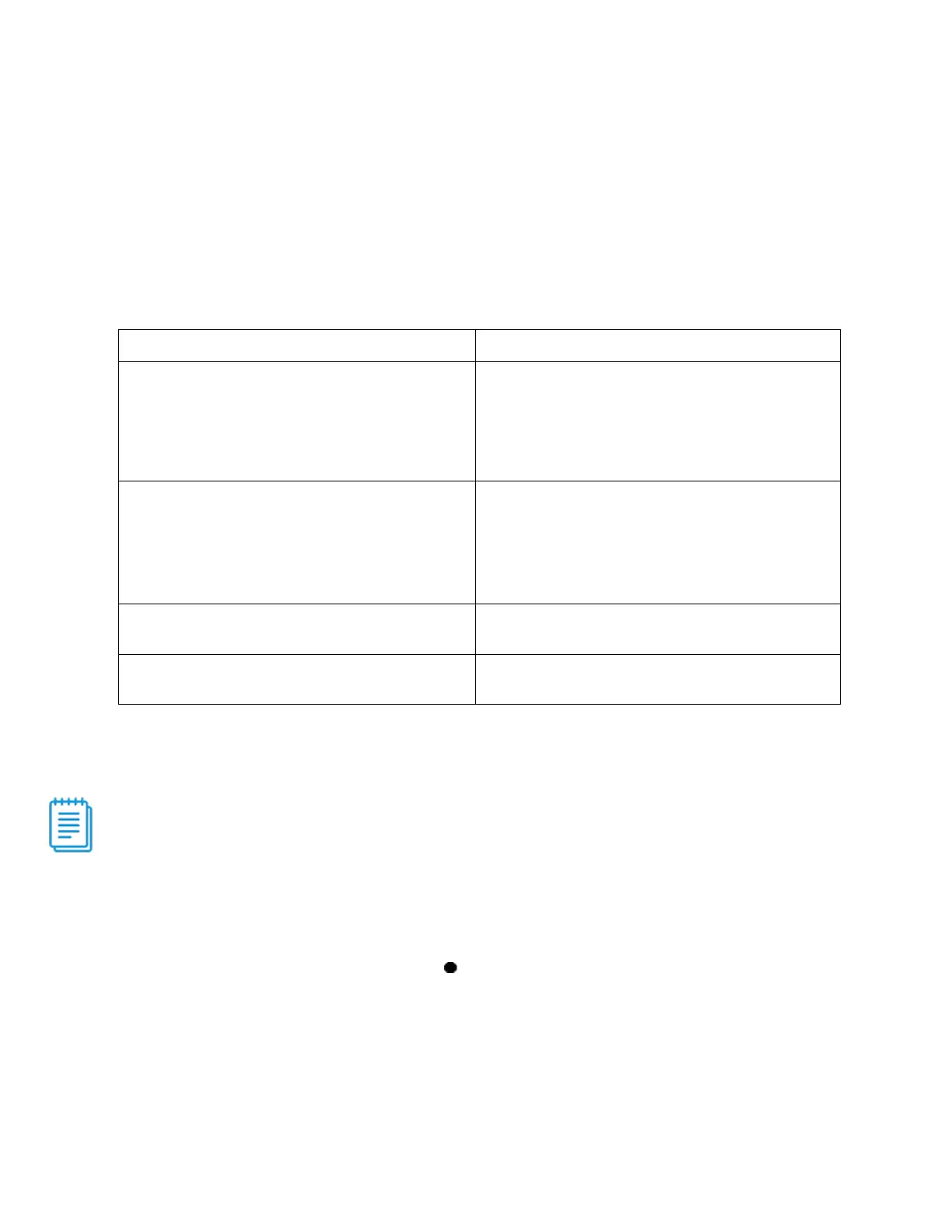

RECOMMENDED CLEANING SCHEDULE

Frequency Equipment

Daily

• Button panel

• Catch tray

• Valve area

• Self-serve dispense handles or

Inspect and clean as required when new

product is loaded.

Refillable tanks must be thoroughly cleaned,

and tubes replaced regularly.

• Product case/product case insert

(if present)/ramp/refillable tank

• Product compartment

Once a month or more frequently as required

• Valve assembly and front panel

• Door gasket

Every six months

• Condenser

• Fan and inner body

Table 6: Recommended cleaning schedule

EXTERIOR

A stainless-steel cleaner is recommended for stainless-steel surfaces. Spray cleaner on a clean cloth

and wipe the exterior.

Do not use stainless-steel cleaner on the button panel or any plastic parts. Do not use any ammonia-

based cleaners, such as a window cleaner.

BUTTON PANEL (PORTION-CONTROL MODELS)

The button panel should be cleaned daily.

1. Press and hold the panel disable button ( ) until the button panel lights flash in sequence.

2. Wipe exterior surfaces, using a soft cloth dampened with warm, clean, soapy water.

3. Wipe using a soft cloth dampened with warm, clean water.

4. Dry with a soft cloth to prevent water spotting.

5. The button panel will automatically return to normal operating mode after 10 – 15 seconds (for

portion control models only).

Loading...

Loading...