MPC-385 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

Command Sequence Formatting: Each command

sequence consists of at least one byte, the first of

which is the “command byte”. Those commands that

have parameters or arguments require a sequence of

bytes that follow the command byte. No delimiters

are used between command sequence arguments,

and command sequence terminators are not used.

Although most command bytes can be expressed as

ASCII displayable/printable characters, the rest of a

command sequence must generally be expressed as a

sequence of unsigned byte values (0-255 decimal; 00

– FF hexadecimal, or 00000000 – 11111111 binary).

Each byte in a command sequence transmitted to the

controller must contain an unsigned binary value.

Attempting to code command sequences as “strings”

is not advisable. Any command data returned by the

controller should be initially treated as a sequence of

unsigned byte values upon reception. Groups of

contiguous bytes can later be combined to form

larger values, as appropriate (e.g., 2 bytes into 16-bit

“word”, or 4 bytes into a 32-bit “long” or “double

word”). For the MPC-200, all axis position values

(number of microsteps) are stored as “unsigned

long” 32-bit positive-only values, and each is

transmitted and received to and from the controller

as four contiguous bytes.

Axis Position Command Parameters: All axis

positional information is exchanged between the

controller and the host computer in terms of

microsteps. Conversion between microsteps and

microns (micrometers) is the responsibility of the

software running on the host computer (see

Microns/microsteps conversion

table for conversion

factors).

Microsteps are stored as positive 32-bit values

(“long” (or optionally, “signed long”), or “unsigned

long” for C/C++; “I32” or “U32” for LabVIEW).

“Unsigned” means the value is always positive;

negative values are not allowed. The positive-only

values can also be stored in signed type variables, in

which case care must be taken to ensure that only

positive values are exchanged with the controller.

The 32-bit value consists of four contiguous bytes,

with a byte/bit-ordering format of Little Endian

(“Intel”) (most significant byte (MSB) in the first

byte and least significant (LSB) in the last byte). If

the platform on which your application is running is

Little Endian, then no byte order reversal of axis

position values is necessary. Examples of platforms

using Little Endian formatting include any system

using an Intel/AMD processor (including Microsoft

Windows and Apple Mac OS X).

If the platform on which your application is running

is Big Endian (e.g., Motorola PowerPC CPU), then

these 32-bit position values must have their bytes

reverse-ordered after receiving from, or before

sending to, the controller. Examples of Big-Endian

platforms include many non-Intel-based systems,

LabVIEW (regardless of operating system & CPU),

and Java (programming language/environment).

MATLAB and Python (script programming

language) are examples of environments that adapt

to the system on which each is running, so Little-

Endian enforcement may be needed if running on a

Big-Endian system. Some processors (e.g., ARM) can

be configured for specific endianess.

Microsteps and Microns (Micrometers): All

coordinates sent to and received from the controller

are in microsteps. To convert between microsteps

and microns (micrometers), use the following

conversion factors (multipliers):

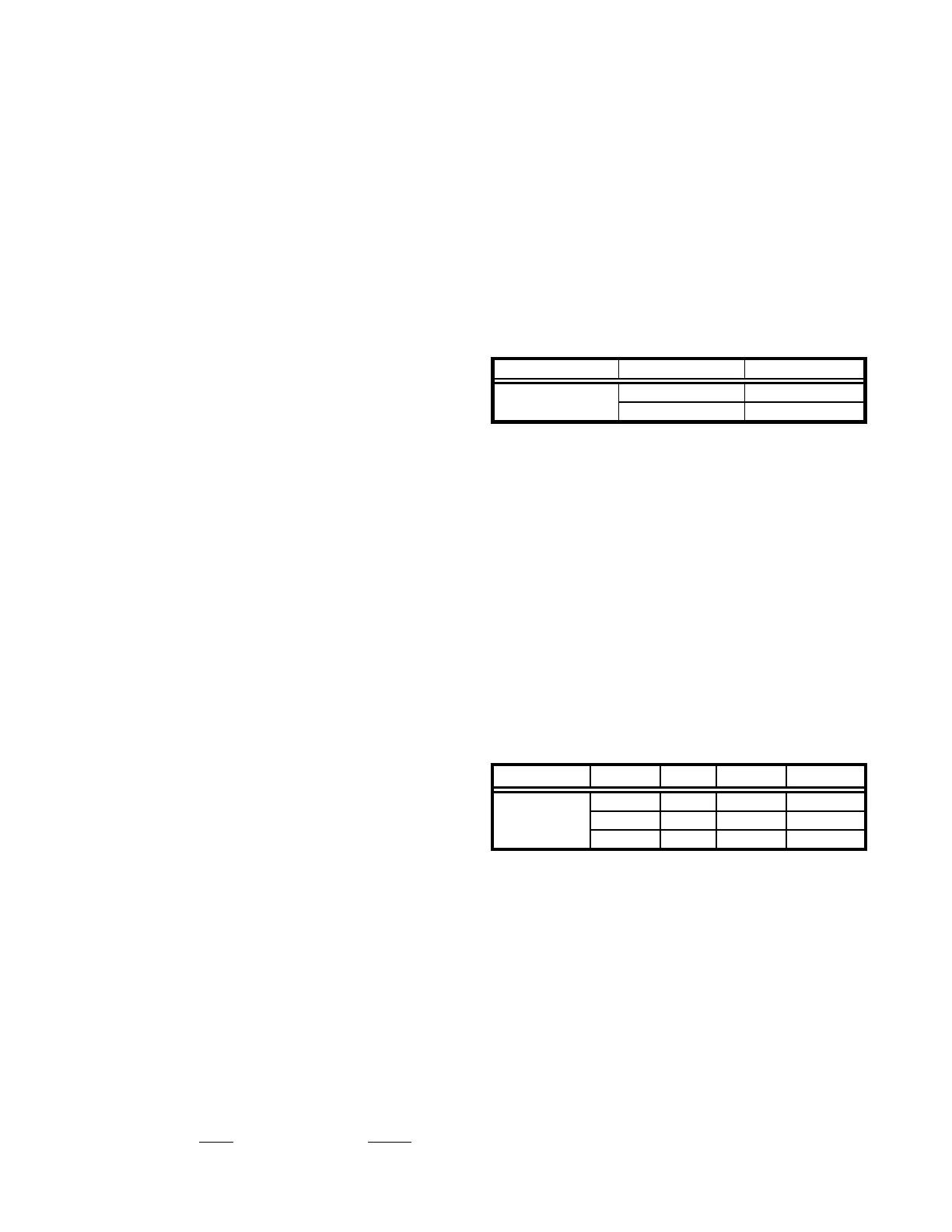

Table E-6. Microns/microsteps conversion factors (multipliers).

micromanipulator

* Same applies to MP-225/M & MP-265/M micromanipulators,

3DMS/M & MPC-x8-series stages, and MOM & SOM microscope

objective movers. Other devices:

1.

MP-x45[S]/M series micromanipulator

(µstepsµm 0.046875; µmµsteps 21.333333333);

2.

MT-8x0 (MT-22xx) series translator

(µstepsµm 0.078125; µmµsteps 12.8 µsteps)

For accuracy in your application, type these

conversion factors as “double” (avoid using the

“float” type as it lacks precision with large values).

When converting to microsteps, type the result as a

32-bit “unsigned long” (C/C++), “uint32”

(MATLAB), or “U32” (LabVIEW) integer (positive

only) value. When converting to microns, type the

result as a “double” (C/C++, MATLAB) or “DBL”

(LabVIEW) 64-bit double-precision floating-point

value.

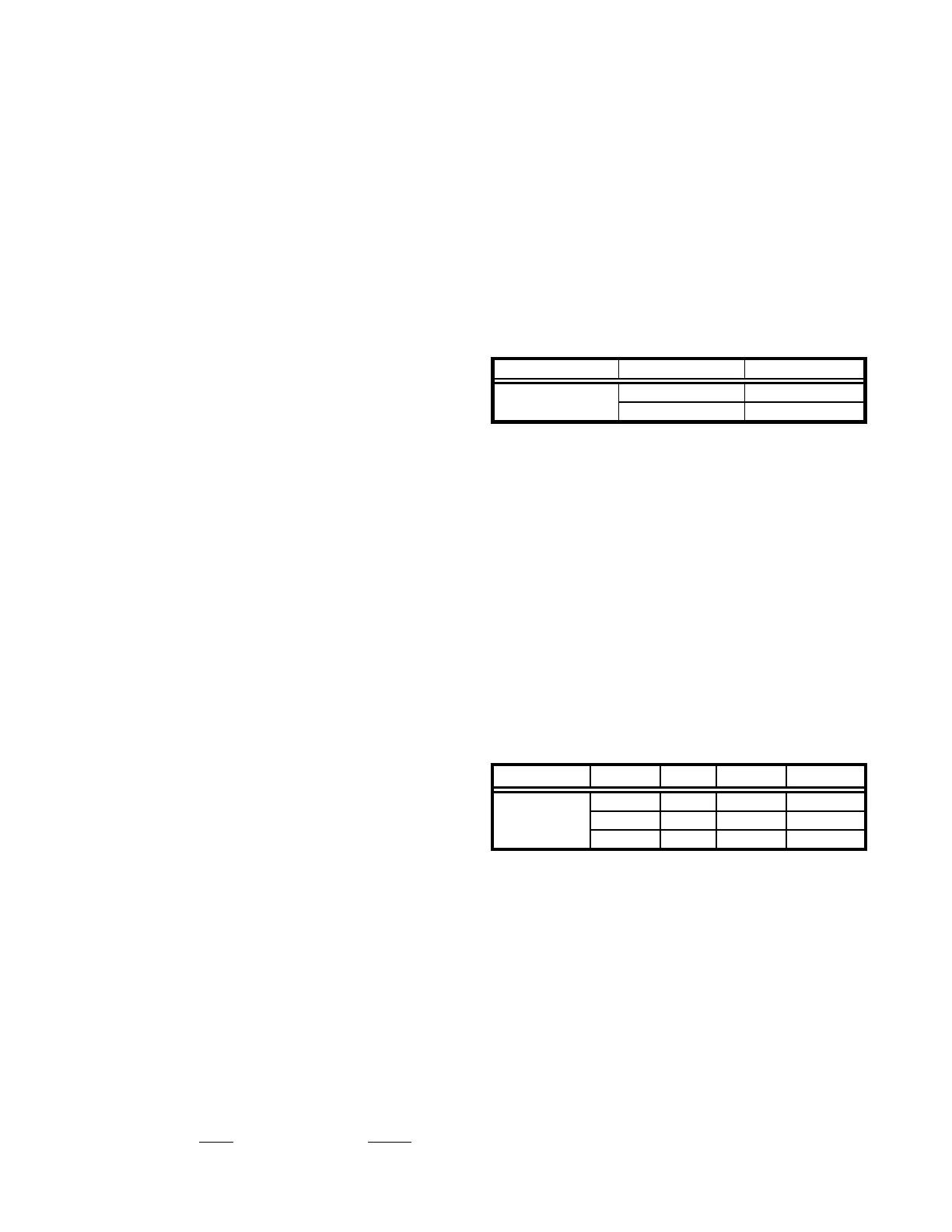

Table E-7. Ranges and bounds.

* Same applies to MP-225/M & MP-x45[S]/M-series

micromanipulators, 3DMS/M series stages, and SOM objective

mover.

Other devices:

•

TRIO MP-x45/M series micromanipulator and MPC-x8 series

stages: 25mm (533,333 microsteps) for X, Y, & Z. (Requires

firmware v3.19+.)

•

TRIO MP-865/M micromanipulator: 50mm for X, 12.5mm for

Y, and 25mm for Z. (Requires firmware v3.21+.)

•

MP-265/M micromanipulator: 25mm for X & Z, 12.5mm for

Y. (Discontinued product – replaced by TRIO MP-865/M.)

•

MT-8x0 (MT-22xx) series translator: 22mm in all three axes.

Only X & Y are connected to a motor (Z can be optionally

connected to a motor of another device (e.g., a focus drive)).

•

MOM objective mover (firmware v3.13 or 3.16, and device

Port A only): 21.5mm in all three axes.

Travel Speed: The following table shows the travel

speeds for single-, double-, and triple-axis

Loading...

Loading...