66

MPC-385 SERIES OPERATION MANUAL – REV. 3.21K (20201120)

physical Origin position is fixed at beginning of travel (BOT).

This means that all higher positions (towards end of travel

(EOT)) are positive values; there are no lower positions and

therefore no negative values are allowed.

7. Absolute vs. Relative Positioning: Current position (‘c’) and

move commands always use absolute positions. All positions

can be considered “relative” to the Origin (Position 0), but all

are in fact absolute positions. Any position that is considered

to be “relative” to the current position, whatever that might

be, can be handled synthetically by external programming.

However, care should be taken to ensure that all relative

position calculations always result in correct positive absolute

positions before initiating a move command.

Declaring relative position variables in C/C++:

/* relative positions for X, Y, & Z */

double rp_x_um, rp_y_um, rp_z_um; /* microns */

/* initialize all relative positions to 0 after

declaring them */

rp_x_um = rp_y_um = rp_z_um = 0;

Enter any positive or negative value for each relative position (e.g.,

rp_x_um = 1000; rp_y_um = 500; rp_z_um = -200 … etc.

For each axis, check to make sure that the new resultant absolute

position (to which to move) is within bounds. Reset the relative

position to 0 if not. If relative value is negative, its positivized value

must not be greater than the current position. Otherwise, if

positive, adding current position with relative position must not

exceed the maximum position allowed. If out of bounds, resetting

relative position to 0 allow the remaining conversions and

movement to resolve without error.

/* check to make sure that relative X is within

bounds */

if ( ( rp_x_um < 0 && abs(rp_x_um) > cp_x_um ) ||

(cp_x_um + rp_x_um > max_x_um) ) /* out of

bounds? */

rp_x_um = 0; /* yes, so reset relative pos. to

0 */

Repeat the above bounds check for each of the remaining axes.

For each axis, calculate new absolute position in microns and then

convert to microsteps before issuing a move command.

/* convert X relative position to absolute

position */

sp_x_um = cp_x_um + rp_x_um; /* add relative pos.

to current pos. */

/* convert new absolute X position in microns to

microsteps */

sp_x_us = sp_x_um * um2usCF;

Repeat for each of the remaining axes as required before issuing a

move command.

8. Position Value Typing: All positions sent and received to and

from the controller are in microsteps and consist of 32-bit

integer values (four contiguous bytes). Position values in

microsteps are always positive, so data type must be an

“unsigned” integer that can hold 32 bits of data. Although

each positional value is transmitted to, or received from, the

controller as a sequence of four (4) contiguous bytes, for

computer application computational and storage purposes

each should be typed as an unsigned 32-bit integer (“unsigned

long” in C/C++; “uint32” in MATLAB, “U32” in LabVIEW,

etc.).

Position values in microns (micrometers or µm) should be data

typed as double-precision floating point variables (“double” in

C/C++ and MATLAB, “DBL” in LabVIEW, etc.).

Note that in Python, incorporating the optional NumPy

package brings robust data typing like that used in C/C++ to

your program, simplifying coding and adding positioning

accuracy to the application.

9. Position Value Bit Ordering: All 32-bit position values

transmitted to, and received from, the controller must be

bit/byte-ordered in “Little Endian” format. This means that

the least significant bit/byte is last (last to send and last to

receive). Byte-order reversal may be required on some

platforms. Microsoft Windows, Intel-based Apple Macintosh

systems running Mac OS X, and most Intel/AMD processor-

based Linux distributions handle byte storage in Little-Endian

byte order so byte reordering is not necessary before

converting to/from 32-bit “long” values. LabVIEW always

handles “byte strings” in “Big Endian” byte order irrespective

of operating system and CPU, requiring that the four bytes

containing a microsteps value be reverse ordered before/after

conversion to/from a multibyte type value (I32, U32, etc.).

MATLAB automatically adjusts the endianess of multibyte

storage entities to that of the system on which it is running, so

explicit byte reordering is generally unnecessary unless the

underlying platform is Big Endian. If your development

platform does not have built-in Little/Big Endian conversion

functions, bit reordering can be accomplished by first

swapping positions of the two bytes in each 16-bit half of the

32-bit value, and then swap positions of the two halves. This

method efficiently and quickly changes the bit ordering of any

multibyte value between the two Endian formats (if Big

Endian, it becomes Little Endian, and if Little Endian, it

becomes then Big Endian).

10. Travel Lengths and Durations: “Move” commands might

have short to long distances of travel. If not polling for return

data, an appropriate delay should be inserted between the

sending of the command sequence and reception of return

data so that the next command is sent only after the move is

complete. This delay can be auto calculated by determining

the distance of travel (difference between current and target

positions) and rate of travel. This delay is not needed if polling

for return data. In either case, however, an appropriate

timeout must be set for the reception of data so that the I/O

does not time out before the move is made and/or the delay

expires.

11. Orthogonal Move Speed: Full speed for the “Orthogonal Move

‘M’” command is 5000 microns/sec. (5 mm/sec. or

microns/millisecond) for single-axis movements (3000 µm/sec.

(3 mm/sec. or µm/ms) for MP-225/M).

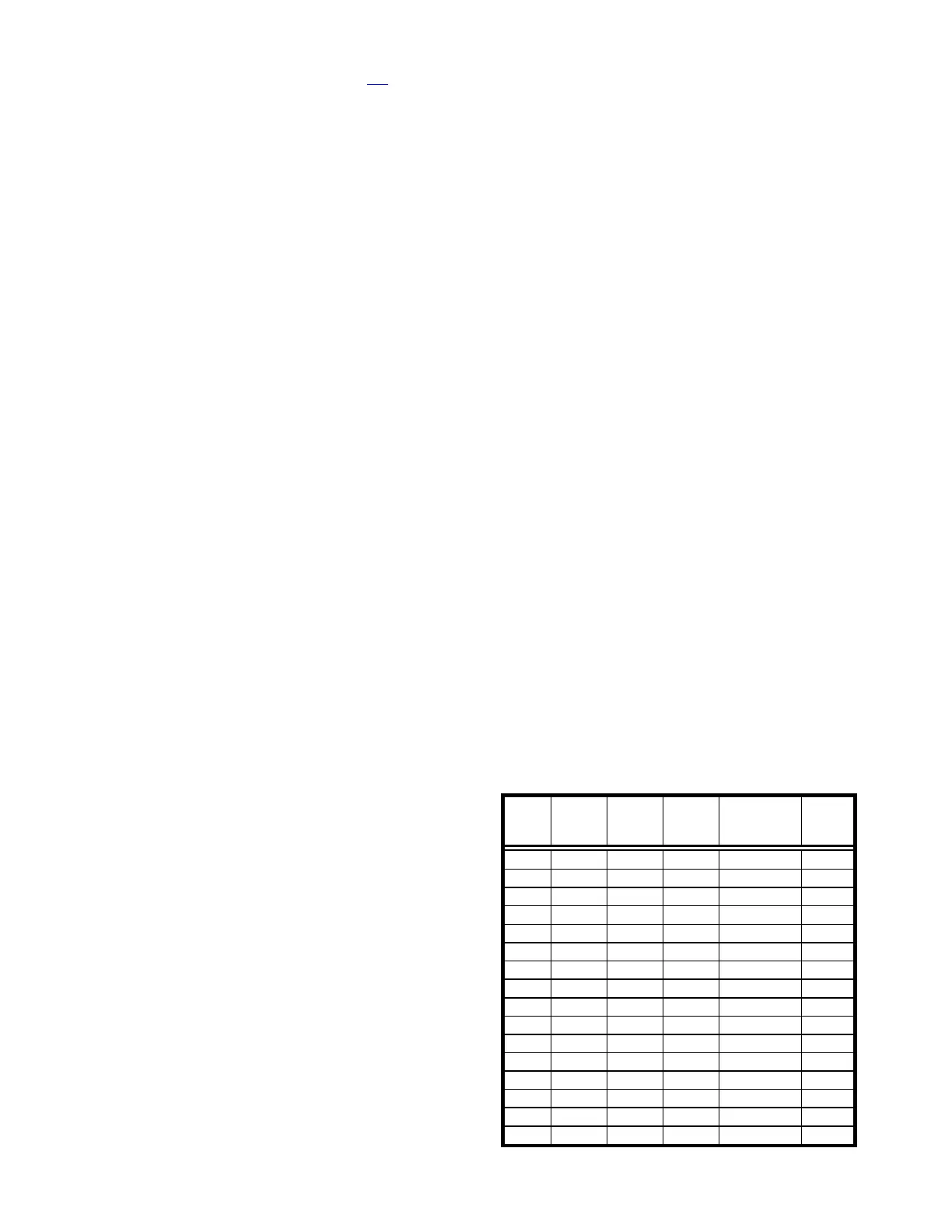

12. Straight-Line Move Speeds: Actual speed for the “Straight-

Line Move ‘S’“ command can be determined with the

following formula: (1300 / 16) * (sp +1), where 1300 is the

maximum speed in microns/second and “sp” is the speed level

0 (slowest) through 15 (fastest). For mm/second or

microns/millisecond, multiply result by 0.001.

Table E-10. Straight-line move ‘S’ command speeds.

Loading...

Loading...