174 Power Amplifier Disassembly and Reassembly TB8100 Service Manual

© Tait Electronics Limited September 2006

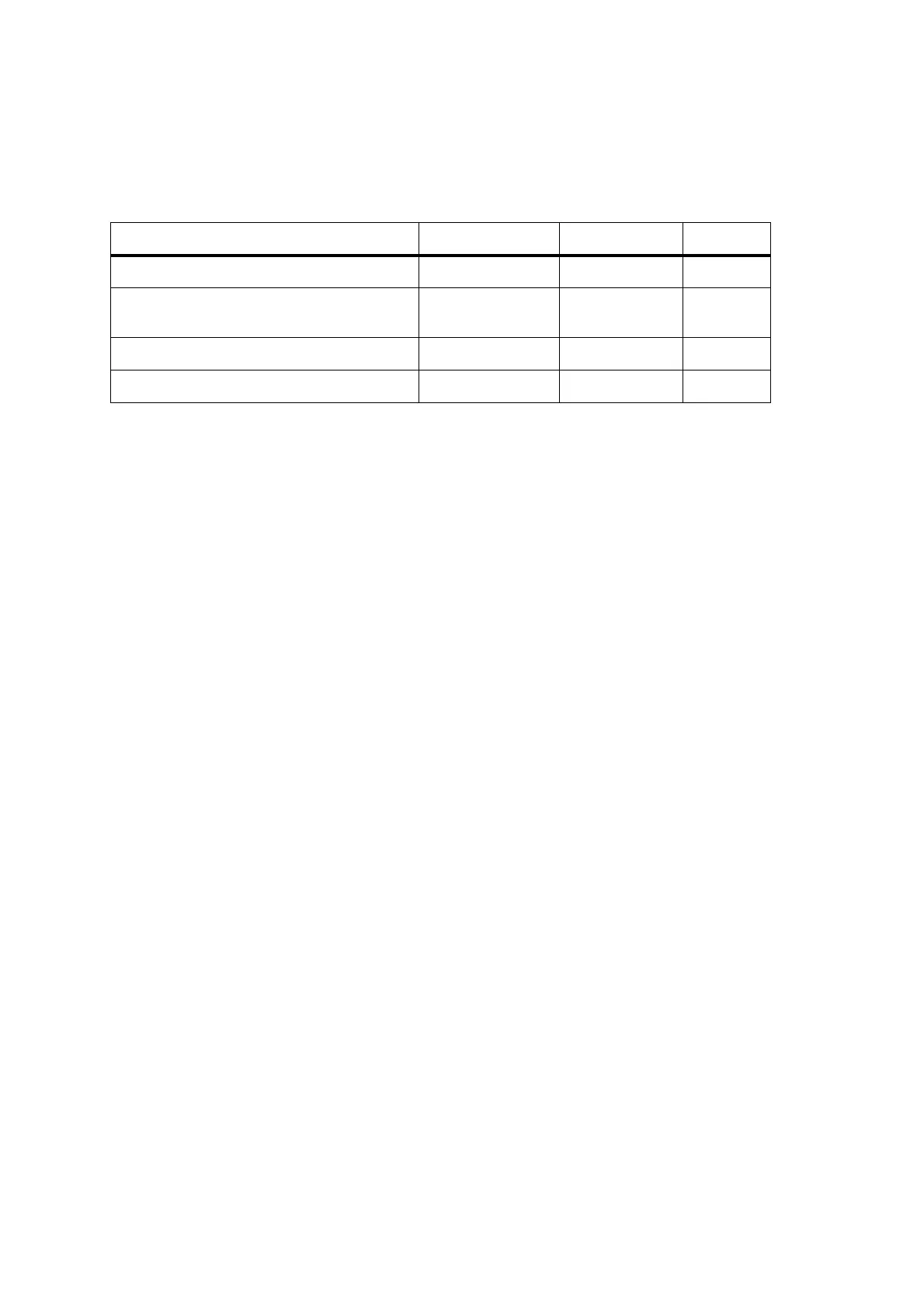

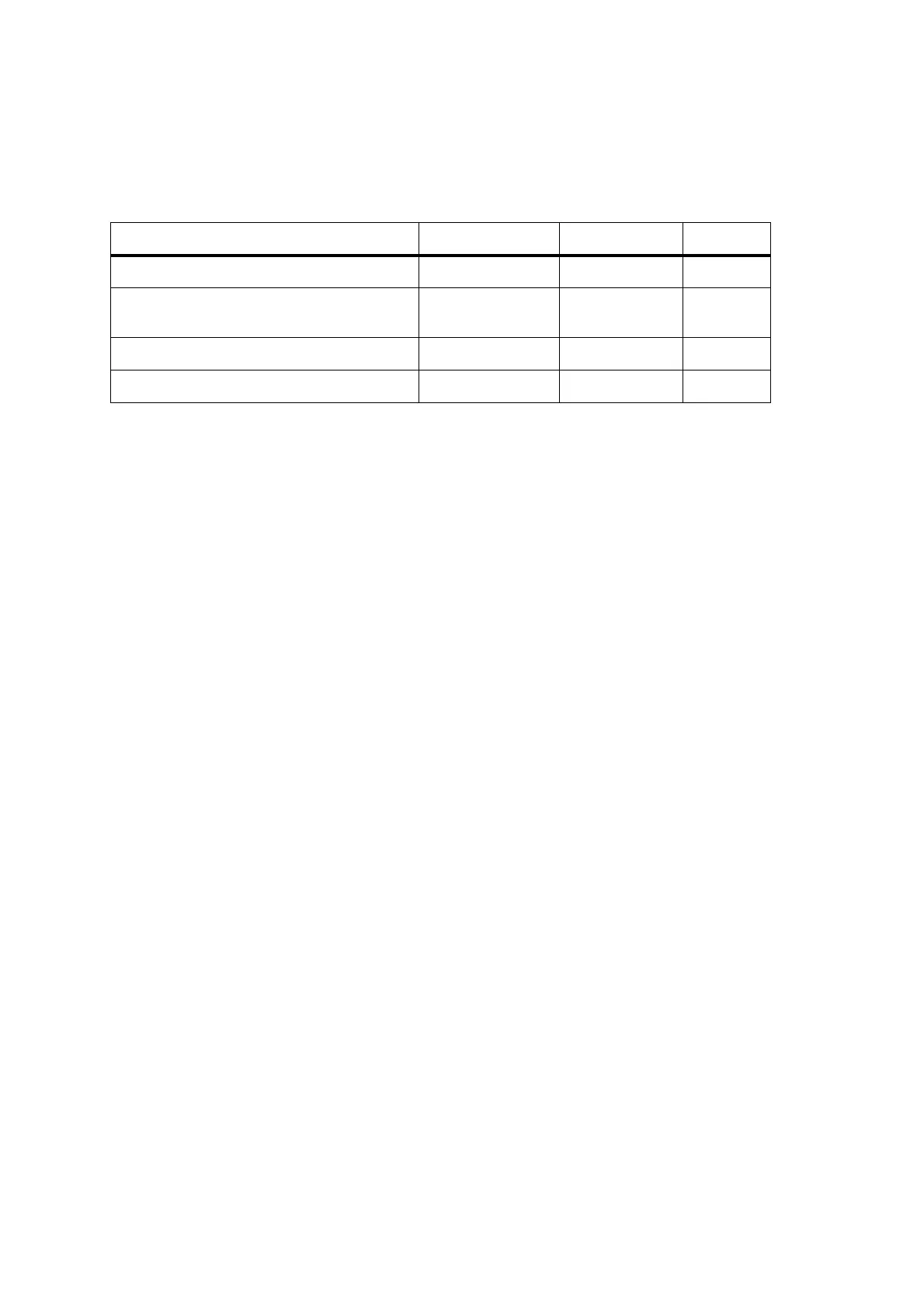

9.1 Screw Torque Settings

The recommended torque settings for the screws used in the PA are as

follows:

9.2 Removing the Airflow Duct and Cover

The circled numbers in the following instructions refer to Figure 9.1.

Airflow Duct

(100W PA Only)

1. Remove the M3 Torx screw b securing the P-clip and DC input

cable to the airflow duct.

2. Remove the M3 Torx screws

c securing the airflow duct to the

heatsink. Lift the airflow duct off the heatsink.

Cover 1. Remove the M3 Torx screws securing the cover to the heatsink and

to the front panel.

2. Remove the two M3 Torx screws securing the N-type connector to

the cover

d.

3. Carefully lift the cover straight up off the heatsink, being careful not

to put any strain on the N-type connector.

Location / Function Torque Driver Size

secure the RF power transistors to the heatsink 0.6N·m / 5.0lbf·in 3/32in Allen key 4–40 UNC

secure the VHF splitter and combiner boards to

the heatsink

0.23N·m / 2.0lbf·in PZ1 M2

secure the SMA connector to the front panel 0.3N·m / 2.5lbf·in T8 M2.5

M3 screws are used in all other locations 0.5N·m / 4.5lbf·in T10 M3

Loading...

Loading...