90 General Information TP9100 Service Manual

© Tait Electronics Limited May 2005

Can Removal

and Installation

Cans are best removed and installed using a can-removal tool. If this tool is

available, technicians should refer to the documentation supplied with the

tool for the correct procedures. If the tool is not available, a hot-air tool may

be used instead. However, technicians require training in the best techniques

to employ in the absence of a can-removal tool. Such training is part of the

accreditation process for service centers.

Spare Cans It is good practice to discard any can that has been removed and replace it

with a spare can. If this is not done, special precautions are needed when re-

installing the original can. These precautions are discussed as part of the

training for accreditation.

4.7 SMT Repair Techniques

Standard

Procedures

Service centers carrying out level-2 repairs are expected to be familiar with

the standard techniques for the replacement of SMT components. However,

certain components on the main board require non-standard techniques and

these are discussed below. Another issue of concern is the procedure for

removing and installing cans. A discussion of the issue concludes this section.

Non-standard

Procedures

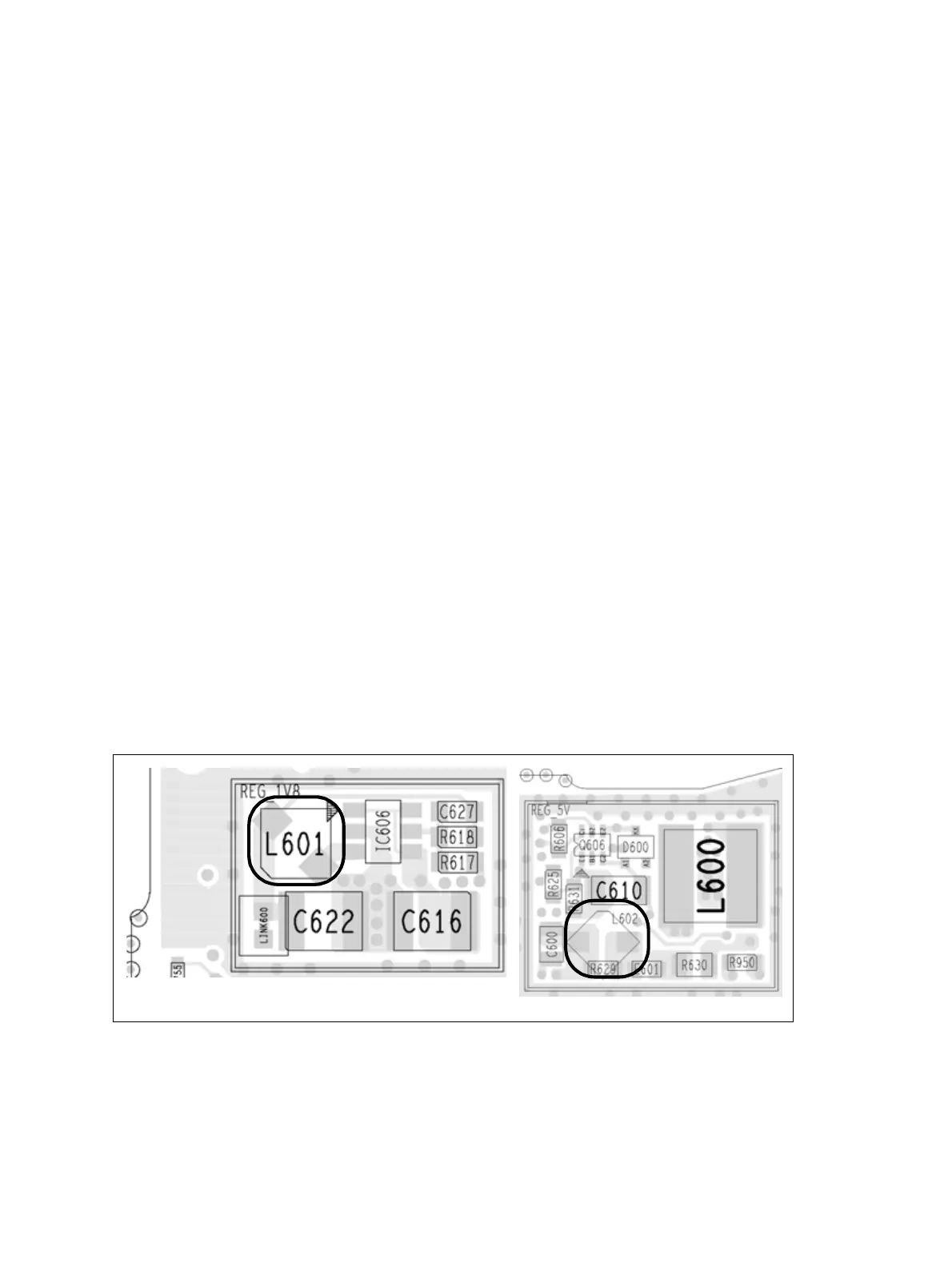

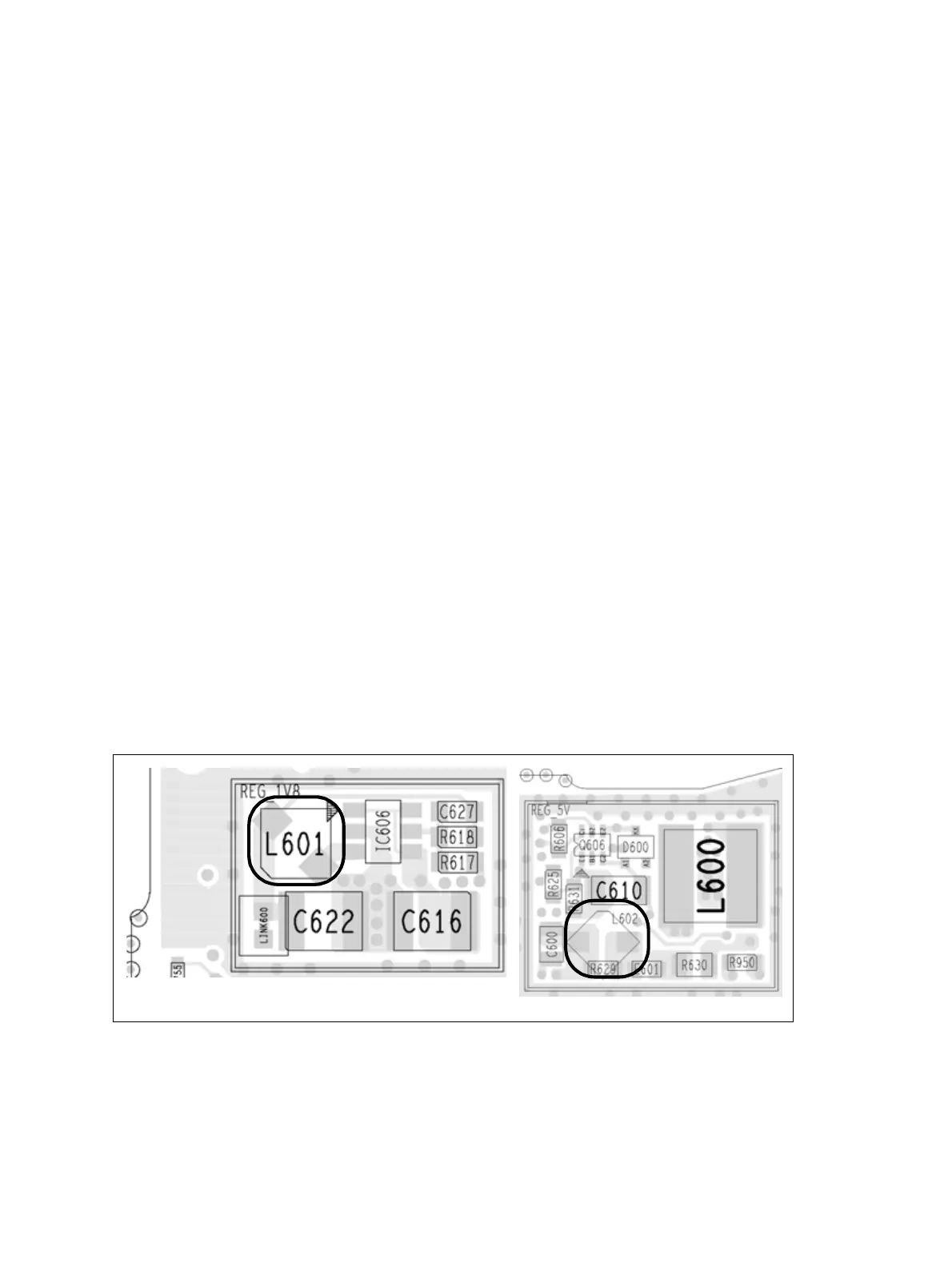

Do not use the standard SMT repair techniques when replacing the

inductors L601 and L602. The standard techniques tend to produce

excessive heat, which will damage these components. Do not use a hot-air

tool or heat gun. Instead use solder paste and a standard soldering iron with

an iron tip with a specified temperature of 600°F (315°C). The inductors

are part of the SMPS of the power-supply circuitry on the bottom-side of

the board. Figure 4.4 on page 90 shows the locations of the components.

Figure 4.4 Locations of the inductors L601 and L602 (top side)

B1 board (H5 and H6 similar)

Loading...

Loading...