7

User’s manual

2 ASYNCHRONOUS PARAMETERS

The “Asyncrhonous Parameters” are used to control the current or speed of a feedback vector

induction motor. The speed and current reference values are generated by the application. See the

application parameters for further information. As an absolute position value is not required for the

sensors (managed with an optional internal electronic board) incremental TTL Encoders and

incremental Sin/Cos Encoders may be used. Absolute sensors such as Resolver can also be used,

as can digital sensors such as Endat or Hiperface if required.

The “Asyncrhonous Parameters” also manages the auto-tuning test, which is crucial if the control is

to adapt perfectly to the motor and to ensure excellent dynamic performance all-round.

2.1 DRIVE AND MOTOR COUPLING

This section is usefull during motor start-up to obtain the best coupling between drive and

motor. It’s very important to follow the correct sequence explained in the next paragraphs

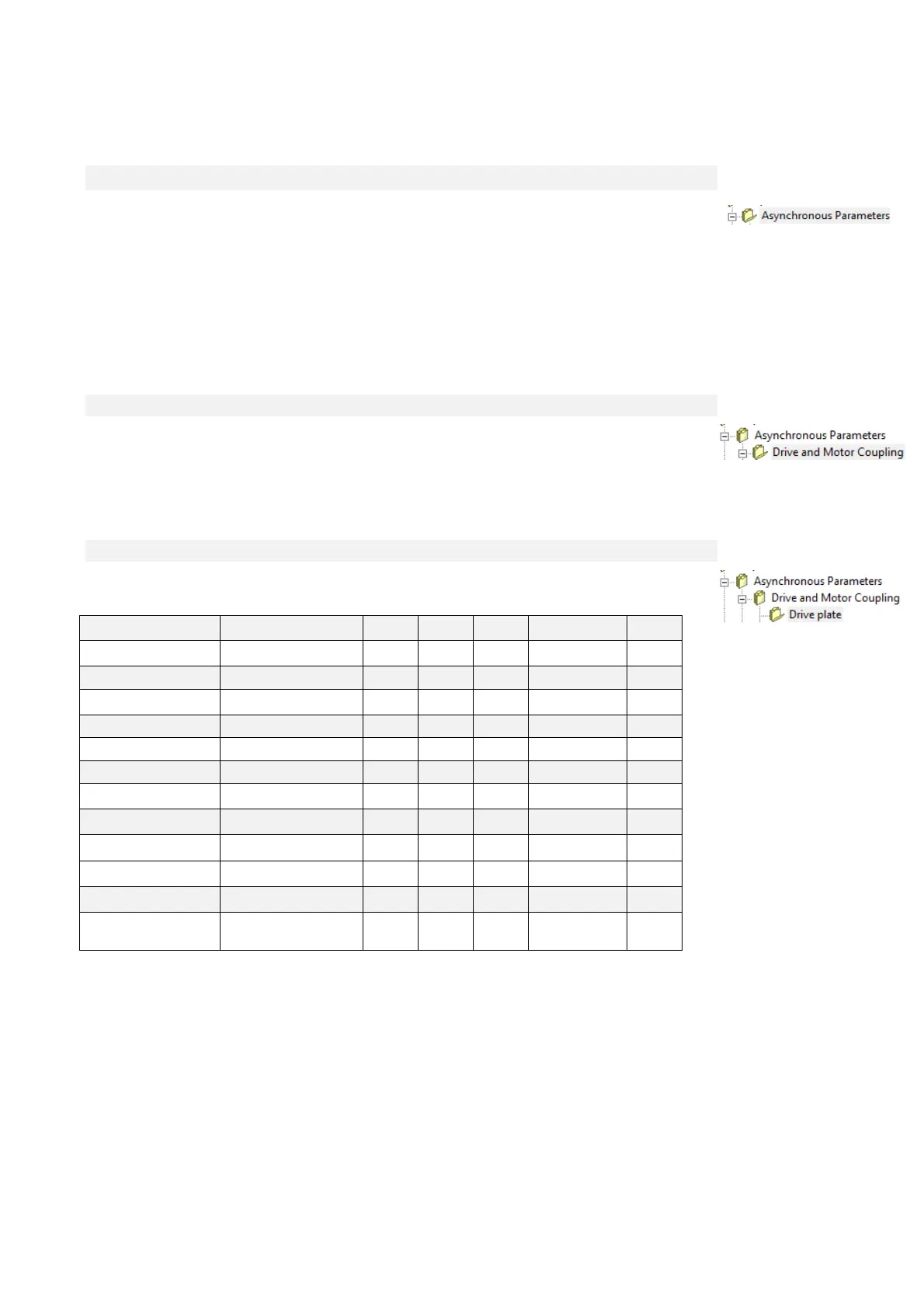

2.1.1 DRIVE PLATE

Name Description Min Max Default UM Scale

MAIN_SUPPLY

P87 - Main Supply

voltage

180.0 780.0 400 V rms 10

DRV_I_NOM P53 - Rated drive current 0.0 3000.0 0 A 10

DRV_I_PEAK

P113 - Maximum drive

current

0.0 3000.0 0 A 10

I_OVR_LOAD_SEL C56 - Current overload 0 3 3 1

PRC_DRV_I_MAX P103 - Drive limit current 0.0 800.0 200 % DRV_I_NOM 40.96

DRV_F_PWM P101 - PWM frequency 1000 16000 5000 Hz 1

DRV_F_PWM_CARATT

P156 - PWM frequency

for drive definition

1000 16000 5000 Hz 1

DRV_E_CARATT

P167 - Characterization

voltage

200.0 690.0 400 V rms 10

DEAD_TIME

P157 - Dead time

duration

0.0 20.0 4 µs 10

T_RAD

P104 - Radiator time

constant

10.0 360.0 80 s 10

T_JUNC

P116 - Junction time

constant

0.1 10.0 3.5 s 10

OVR_LOAD_T_ENV

P155 - Ambient

temperature reference

value during overload

0.0 150.0 40 °C 10

This parameters are related to the drive characteristic. The user has to set only the main supply

voltage and select the current overload.

Loading...

Loading...