97

User’s manual

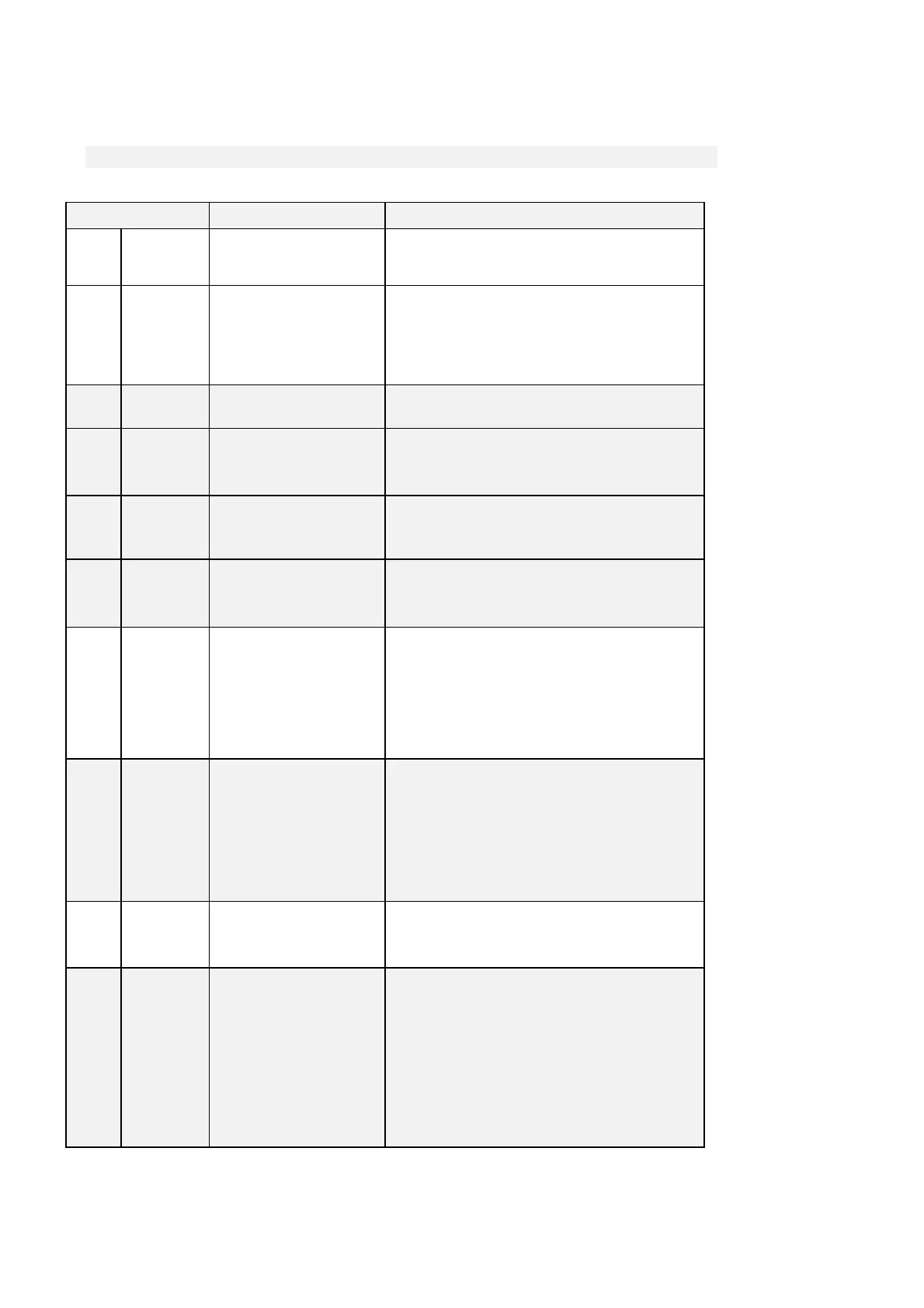

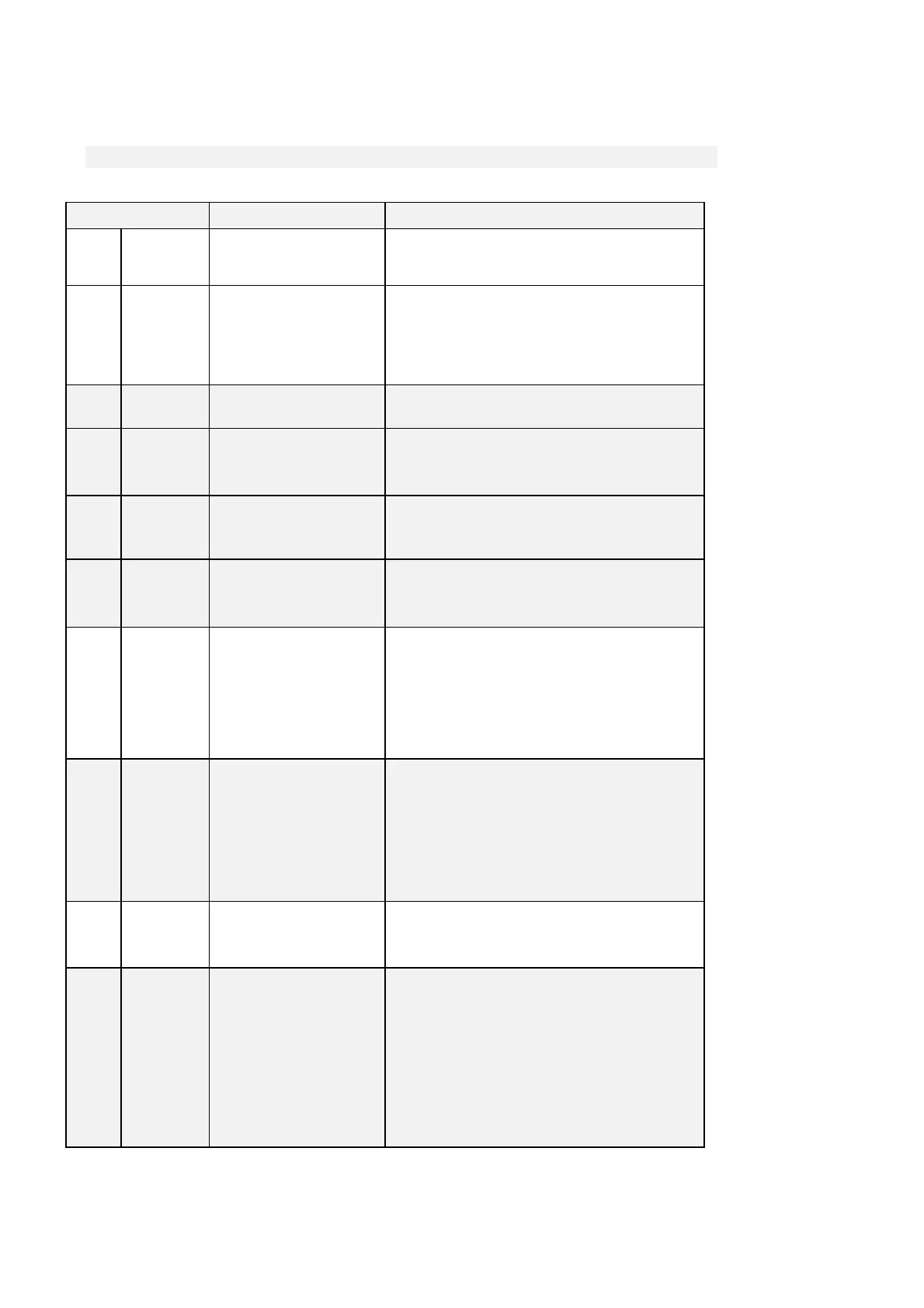

6.1.2 MALFUNCTIONS WITH AN ALARM: TROUBLESHOOTING

ALARM DESCRIPTION CORRECTIVE ACTION

A0.0

Over –current

alarm

It has been measured a current

greater than its limit

Check if in a transient state the active current reference is

increased to high values in a short time. Eventually increase the

current limit regulator gain.

A0.1

Motor

in stall

Drive worked in torque or current

limit for a time equal to P186

seconds

If the motor has to work in limit for a long time, disable this

alarm set C82=0 or lengthen the limit time admitted increasing

P186.

The motor is in stall because it has not been given sufficient

voltage boost at low frequencies: increase the parameter P172.

The start-up load is too high: reduce it or increase the rating of

motor and drive.

A1.0

Loaded default

parameters

EEPROM data related to a

different core

It’s possible to reset this alarm but keep attention: now all

parameters have its default value.

A1.1

EEPROM

Read failure

A Check Sum error occurred

while the EEPROM was reading

the values. Default values loaded

automatically.

Try rereading the values with the EEPROM

. The reading may have been disturbed in some way. If the

problem continues contact TDE as there must a memory

malfunction.

A1.2

EEPROM

Write failure

When data is being written in the

EEPROM the required values are

always shown afterwards: an

alarm triggers if differences are

detected.

Try rewriting the values in the EEPROM

. The information may have been disturbed in some way.

If the problem continues contact TDE as there must be a

memory malfunction.

A1.3

EEPROM

Read and write

failure

Alarms A1.1 and A1.2 appears There are some problems with EEPROM.

A2.0

Motor not

fluxed

Magnetic flux (d27) is below the

minimum flux set in P52.

Check that the motor is properly connected to the drive.

Try to increase parameter P29 (machine magnetizing waiting

time) and reduce P52 if necessary as this specifies the

minimum flux alarm threshold.

Check d27 to ensure that the flux increases when RUN is

enabled.

A3.0 Power failure

The drive output current has

reached a level that has set off an

alarm; this may be caused by an

overcurrent due to leakage in the

wires or the motor or to a short

circuit in the phases at the drive

output. There may also be a

regulation fault.

Check the connection wires on the motor side, in particular on

the terminals, in order to prevent leakages or short circuits.

Check the motor insulation by testing the dielectric strength,

and replace if necessary.

Check the drive power circuit is intact by opening the

connections and enabling RUN; if the safety switch cuts in,

replace the power. If the safety switch cuts in only during

operation, there may be a regulation problem (replace along

with current transducers) or vibrations causing transient D.C.

A4.0

Application

alarm

This alarm is application specific.

Please refer to specific

documentation

A5.0

Motor

temperature too

high

Connection C46 runs a range of

motor heat probes. If C46=1 or 2,

a PTC/NTC is being used and its

Ohm value (d41) has breached

the safety threshold (P95). If C46

= 3 a digital input has been

configured to I23 logical input

function and this input is in not

active state. If C46=4, a KTY84 is

being used: the temperature

reading (d26) must be higher than

the maximum temperature (P91).

Check the temperature reading in d26 and then check the

motor. With a KTY84, if -273.15 appears the electrical

connection towards the motor heat probe has been interrupted.

If the reading is correct and the motor is overheating, check that

the motor cooling circuit is intact. Check the fan, its power unit,

the vents, and the air inlet filters on the cabinet. Replace or

clean as necessary. Ensure that the ambient temperature

around the motor is within the limits permitted by its technical

characteristics.

Loading...

Loading...