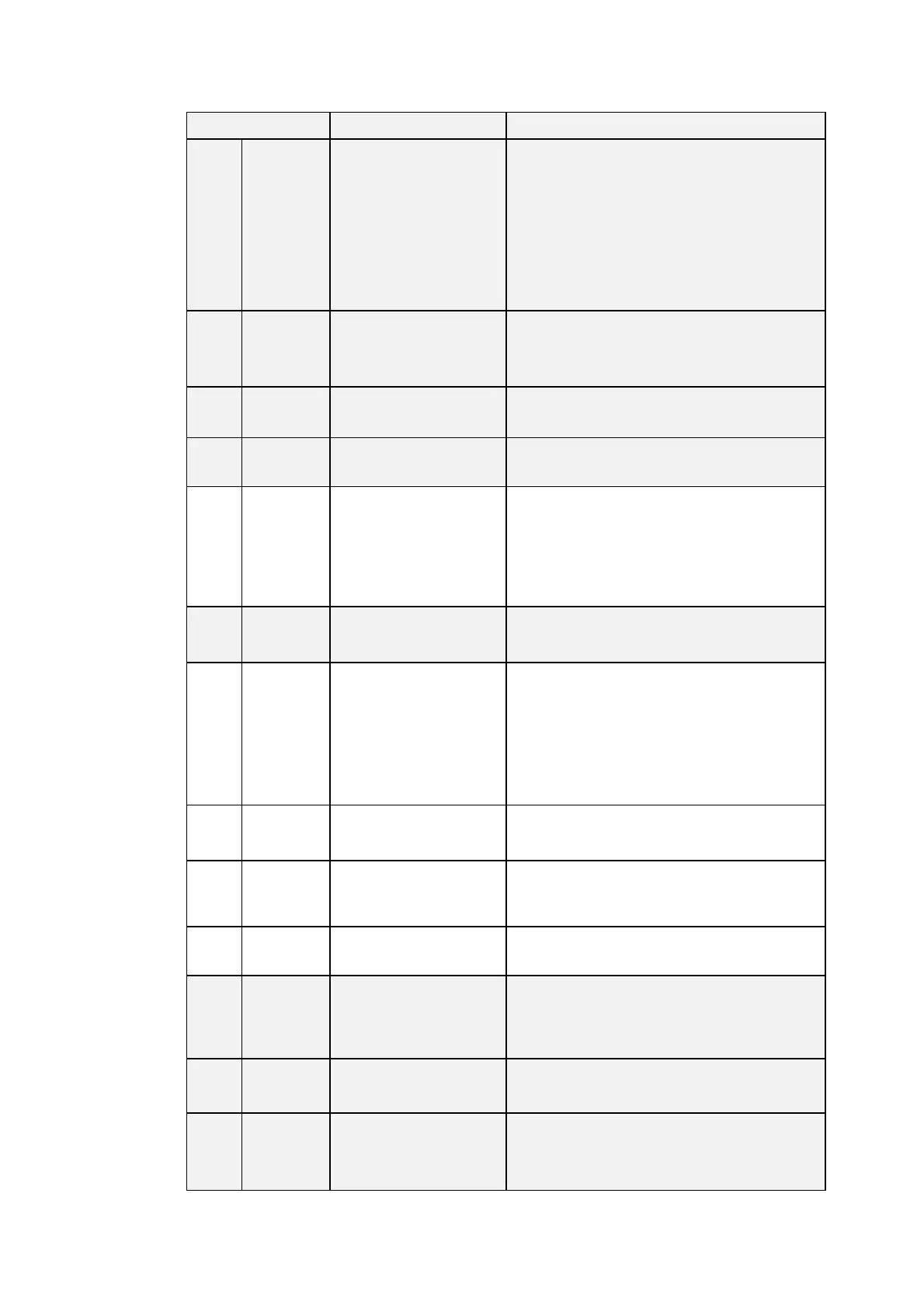

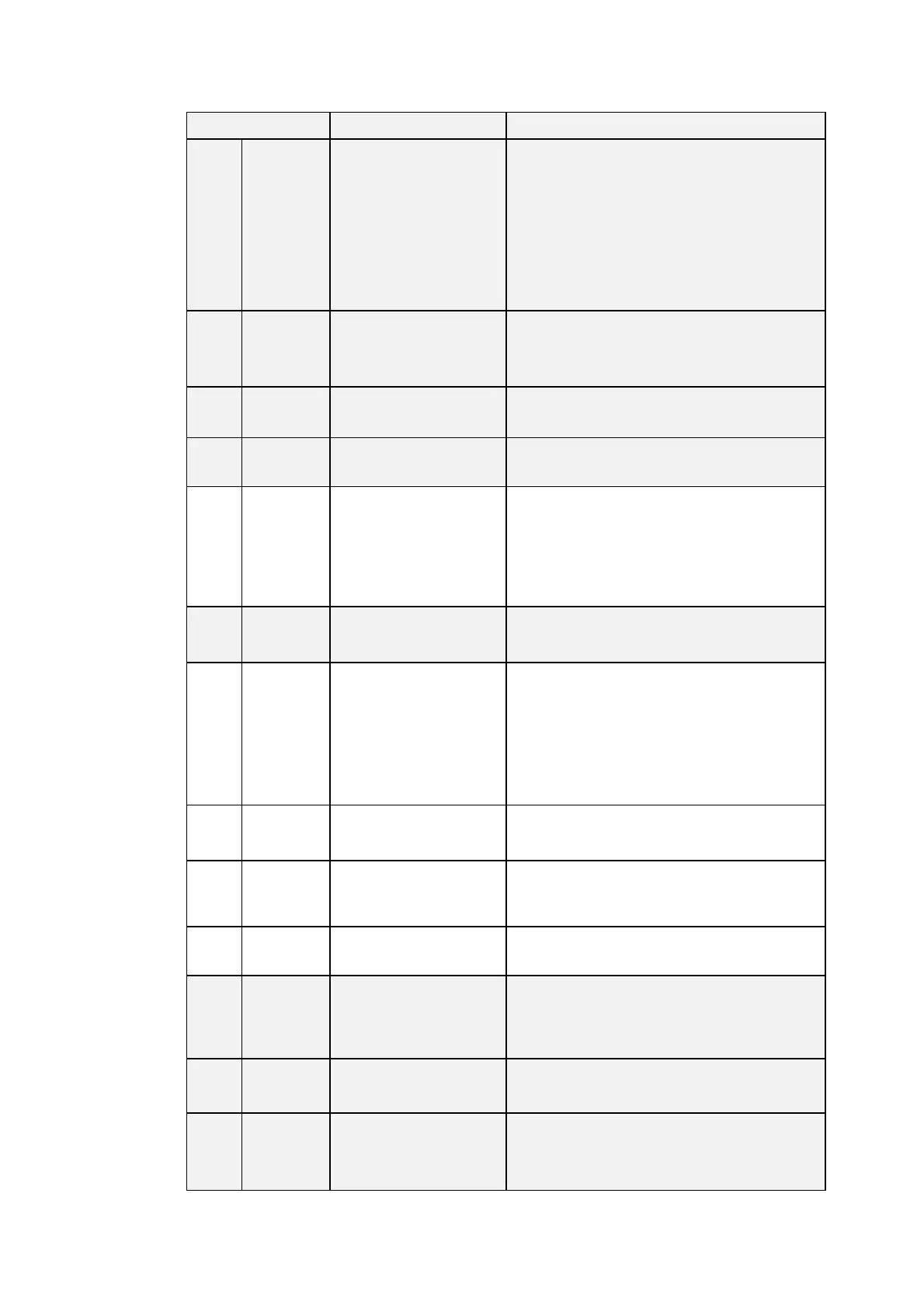

98

ALARM DESCRIPTION CORRECTIVE ACTION

A5.1

Radiator

temperature too

high

The radiator temperature (d25) is

higher than the maximum (P118).

Check the temperature reading on d25 and then check the

radiator. If -273.15 is displayed, the electrical connection

towards the radiator heat probe has been interrupted. If the

reading is correct and the motor is overheating, check that the

drive cooling circuit is intact. Check the fan, its power unit, the

vents, and the air inlet filters on the cabinet. Replace or clean

as necessary. Ensure that the ambient temperature around the

drive is within the limits permitted by its technical

characteristics.

Check parameter P118 is set correctly.

A5.2

Brake

resistance

adiabatic

energy

protection

The Adiabatic Energy

dissipated on Braking

resistance during the time

selected in P144 has

overcame the threshold set

in KJoule in P142

Check the correct setting of parameters P140, P142 and

P144 compared to the Resistance plate. Check the correct

dimensioning of Braking Resistance Maximum Power

related to maximum speed, load inertia and braking time.

A5.3

Brake

resistance

dissipated

power

The Average Power

dissipated on Braking has

overcome the threshold set

in Watt in P146

Check the correct setting of parameters P140, P146 and

P148 compared to the Resistance plate. Check the correct

dimensioning of Braking Resistance Average Power

related to maximum speed, load inertia and braking time

A5.4

Motor thermal

probe not

connected

Thermal probe not detected the

presence.

Verify the presence of the connection of the probe and that it is

correct.

A6.0

Motor I

2

t

thermal alarm

The motor electronic overload

safety switch has cut in due to

excessive current absorption for

an extensive period.

Check the motor load. Reducing it may prevent the safety

switch cutting in.

Check the thermal current setting, and correct if necessary

(P70). Check that the heat constant value is long enough (P71).

Check that the safety heat curve suits the motor type and

change the curve if necessary (C33).

A7.0

Auto-tuning test

unfinished

The RUN command was disabled

during a test. Run command

switched off too early.

Reset the alarms and repeat the test by re-enabling it.

A8.0

Missing enable

logic input from

the field

A digital input has been

configured to I02 logical input

function and this input is in not

active state

The external safety switch has cut in disabling drive enable.

Restore and reset.

The connection has been broken. Check and eliminate the fault.

Input function has been assigned, but enable has not been

given. Authorise or do not assign the function.

A8.1

Watchdog

alarm LogicLab

A LogicLab watchdog alarm on

slow cycle appears

Check if the LogicLab slow task duration is greater than 500 ms

and try to reduce this execution time

A8.2

Fast task

LogicLab too

long

The logicLab fast task is too long

in time

Try to reduce the LogicLab fast task execution time under

admitted limit.

Please refer to the specific documentation.

A8.3

Application out

of service

There is no valid application

running in the drive

Reload the application using OPDExplorer

A9.0

Hardware

board and

firmware are

incompatible

Feedback option card and drive

firmware

incompatible

Check internal values d62 and d63 for the firmware and option

card codes. There must be some irregularity.

A9.1

Sensor

presence

Sensor not connected Check the connection towards the sensor.

A9.2

Overspeed

(more than 10

consecutive

Tpwm)

Overspeed: speed reading higher

than threshold set in P52.

In a transient state, the speed reading has exceeded the

permitted limit. Adjust the speed regulator gains or raise the

limit in P52.

Loading...

Loading...