99

User’s manual

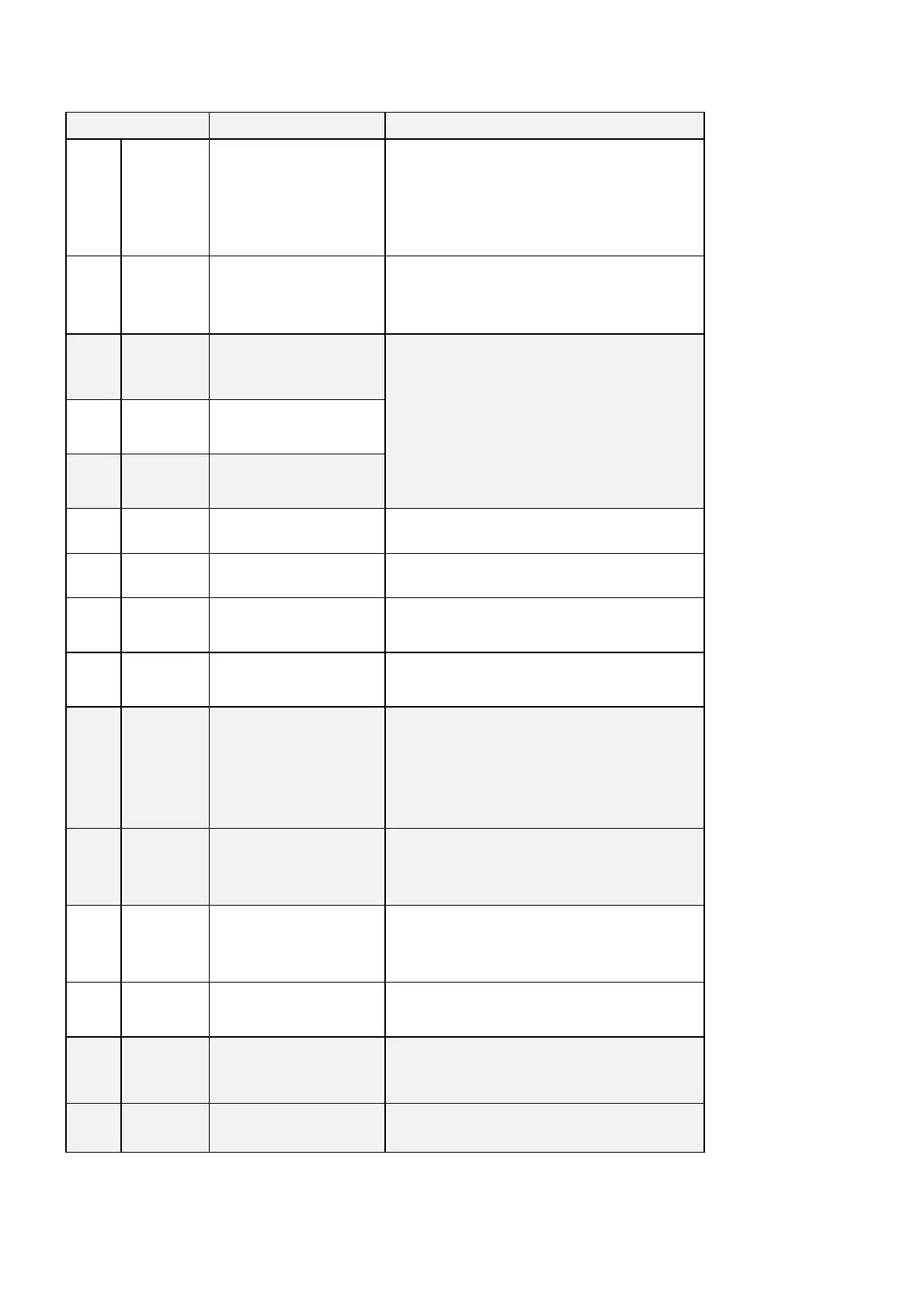

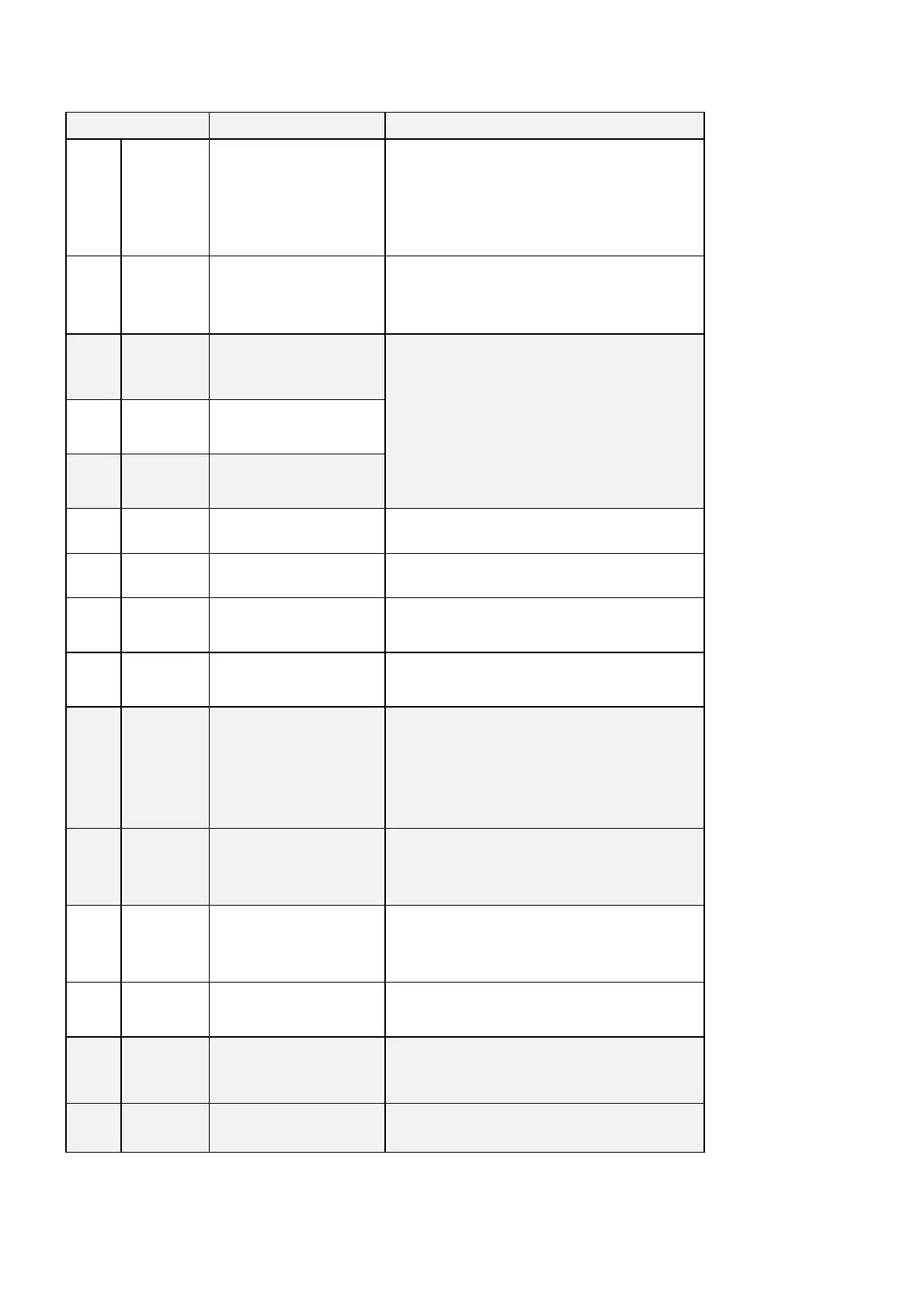

ALARM DESCRIPTION CORRECTIVE ACTION

A10.0

DC Bus under

minimum

threshold

admitted

Intermediate drive circuit voltage

(DC Bus see d24) has dropped

below the minimum value (P106).

Undervoltage may occur when the mains transformer is not

powerful enough to sustain the loads or when powerful motors

are started up on the same line.

Try to stabilise the line by taking appropriate measures. If

necessary, enable the BUS support function for mains failure

(C34=1). This however can only help motors with light loads.

A10.1

Emergency

bracking on

main supply

lost

With connection C34= 3 was

been select the emergency brake

when main supply is lost. This has

occurred

Try to understand why main supply is lost.

A11.1 HW detection

Intermediate drive circuit voltage

(DC Bus see d24) has exceeded

the maximum analog thresold

value.

The safety switch cuts in mainly due to excessively short

braking times. The best solution is to lengthen the braking

times.

An overvoltage in the mains may also trigger the safety switch.

If the drive is fitted with a braking circuit, check that the

resistance value is not too high to absorb the peak power.

If the resistor is not too hot, check the resistor and connection

continuity and ensure that the circuit functions correctly.

A11.2 SW detection

Intermediate drive circuit voltage

(DC Bus see d24) has exceeded

the maximum value (P107).

A11.3

HW + SW

detection

A11.0 and A11.1 appears

A12.0 Software alarm C29 different from 1 Check and enable connection C29 “Drive software enable”

A12.1

Run whitout

power soft start

RUN without Power Soft start Check why the Power Soft start isn’t enabled

A12.2

Run with

T.radiator too

high

RUN with Trad>P119 Check the radiator temperature (d25)

A12.3

Comunication

problems with

power card

Problems in the communication

with the power card

Please contact TDEMacno assistance

A13.0

Rectifier bridge

problem

The bridge that enables the line

by gradually loading the DC bus

condensers has not managed to

load the intermediate drive circuit

sufficiently within the time set

(P154).

Check the voltage of the three input phases.

Try switching off and then back on, measuring the DC Bus level

(with the monitor or tester).

If the problem repeats, contact TDE as there must be a soft

start circuit malfunction.

A13.1

Safe Torque

Off

Safe Torque Off: +24Vare missing

in connectors S1 and S3. For this

reason it’s enabled certified STOP

function

Bring +24V to connectors S1 and S3.

If the user want to use the Safe Torque Off function without

alarms, it’s necessary to set C73=1.

A14.0

Motor phase

inverted

During autotuning was been

detected that motor phase are not

connected in the same order of

feedback

Swap over two phases and repeat the connection tests.

A14.1

Motor not

connected

During autotuning was been

detected that drive and motor

aren’t connected properly

Check motor phases

A15.0

Wrong number

of

Motor/Sensor

poles

Motor/sensor parameters being

written

Number of motor poles (P67) set incorrectly or more sensor

poles (P68) than motor poles have been set.

A15.1

Simulated

encoder pulses

Simulated Encoder pulses

Number of revolutions per pulse selected (C51) is not

compatible with the maximum speed (P65). See “Feedback

Option” enclosure.

Loading...

Loading...