Maintenance—434

1. Check Control Settings. Incorrect control settings

can indicate a trouble that does not exist. If there is any

question about the correct fun ction or operation of any

control, see the Operating Instructions section.

2. Check Associated Equipment. Before proceeding

w ith troubleshooting of the 434, check tha t the equipm ent

used w ith this instrum ent is operating correctly. Check that

the signal is properly connected and tha t the inter

connecting cables are not defective. Also, check the power

source.

3. Visual Check. Visually check the po rtion of the

instrum ent in which the trouble is located. Many troubles

can be located by visual indications such as unsoldered

c o n n e c tio n s , broken wires, damaged circu it boards,

damaged components, etc.

4. Check Instrument Calibration. Check the calibration

of this instrum ent, or the affected circuit if the trouble

appears in one circuit. The apparent trouble may only be a

result of misadjustment or may be corrected by calibration.

Complete calibration instructions are given in the Calibra

tion section.

5. Isolate Trouble to a Circuit. To isolate trouble to a

circuit, note the trouble sym ptom . The sym ptom often

identifies the circu it in which the trouble is located. For

exam ple, poor focus indicates that the CRT c ircu it

(includes high voltage) is probably at fault. When trouble

symptoms appear in more than one circuit, check affected

circuits by taking voltage and waveform readings.

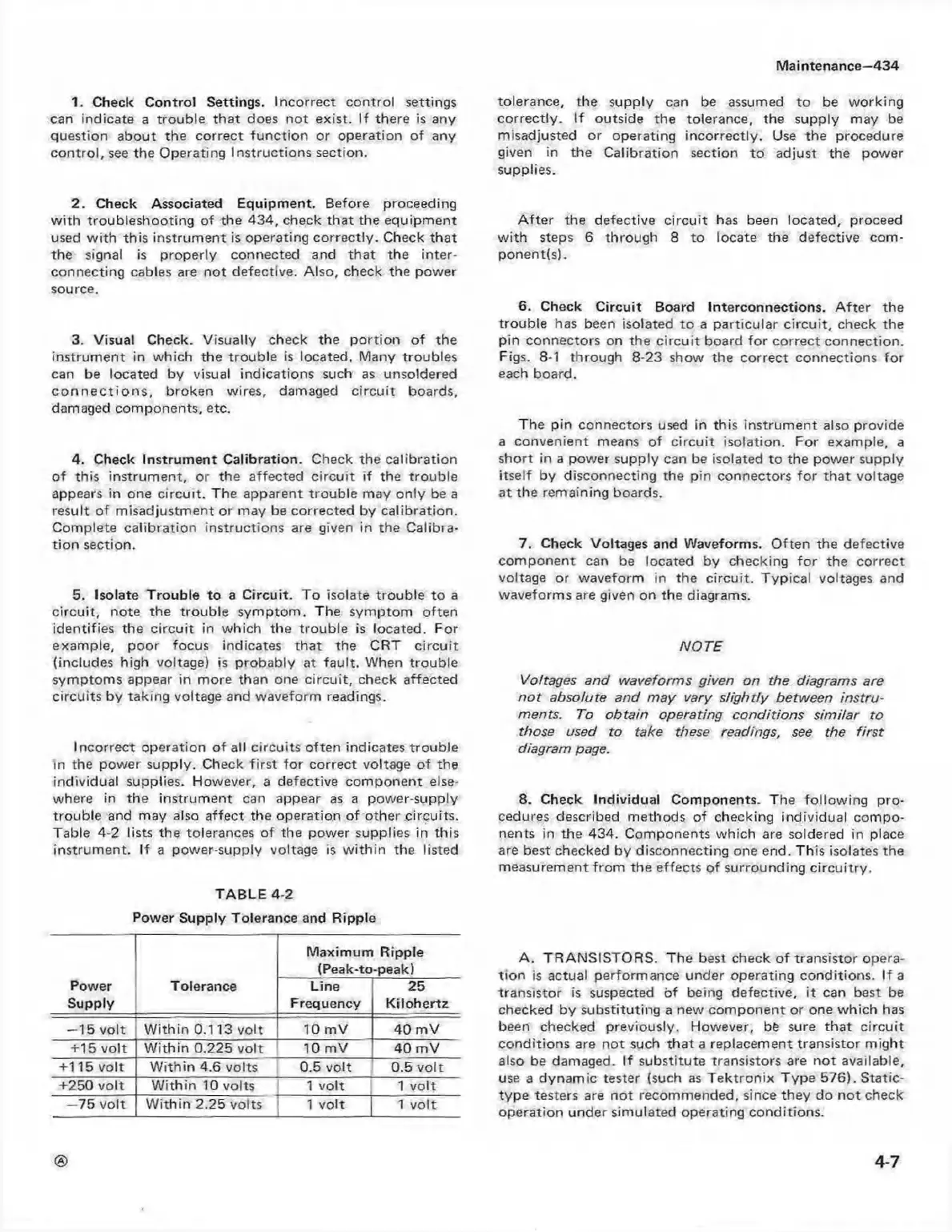

Incorrect operation o f all circuits often indicates trouble

in the power supply. Check firs t fo r correct voltage o f the

individual supplies. However, a defective component else

where in the instrum ent can appear as a power-supply

trouble and may also affect the operation of other circuits.

Table 4-2 lists the tolerances of the power supplies in this

instrum ent. If a power-supply voltage is w ith in the listed

TABLE 4-2

Power Supply Tolerance and Ripple

Power

Supply

Tolerance

Maximum Ripple

(Peak-to-peak)

Line

Frequency

25

Kilohertz

—15 volt

W ithin 0.113 volt 10 mV

40 m V

+15 vo lt W ithin 0.225 volt 10 mV 40 m V

+115 volt W ithin 4.6 volts

0.5 volt 0.5 vo lt

+250 volt W ithin 10 volts

1 volt 1 volt

—75 volt W ithin 2.25 volts 1 volt

1 vo lt

tolerance, the supply can be assumed to be w orking

correctly. If outside the tolerance, the supply may be

misadjusted or operating incorrectly. Use the procedure

given in the Calibration section to adjust the power

supplies.

A fte r the defective circuit has been located, proceed

w ith steps 6 through 8 to locate the defective com

ponents).

6. Check Circuit Board Interconnections. A fter the

trouble has been isolated to a particular circ uit, check the

pin connectors on the circu it board for correct connection.

Figs. 8-1 through 8-23 show the correct connections for

each board.

The pin connectors used in this instrum ent also provide

a convenient means of circu it isolation. For example, a

short in a power supply can be isolated to the power supply

itself by disconnecting the pin connectors for tha t voltage

at the remaining boards.

7. Check Voltages and Waveforms. O ften the defective

com ponent can be located by checking fo r the correct

voltage or waveform in the circuit. Typical voltages and

waveforms are given on the diagrams.

NO TE

Voltages and waveforms given on the diagrams are

n o t absolute and may vary slightly between instru

ments. To obtain operating conditions sim ilar to

those used to take these readings, see the firs t

diagram page.

8. Check Individual Components. The follow ing pro

cedures described methods of checking individual com po

nents in the 434. Components w hich are soldered in place

are best checked by disconnecting one end. This isolates the

measurement from the effects of surrounding circuitry.

A . TRANSISTORS. The best check o f transistor opera

tion is actual performance under operating conditions. If a

transistor is suspected of being defective, it can best be

checked by substituting a new component or one w hich has

been checked previously. However, be sure th at circu it

conditions are not such that a replacement transistor m ight

also be damaged. If substitute transistors are not available,

use a dynam ic tester (such as T ektron ix Type 576). Static-

type testers are not recommended, since they do n o t check

operation under simulated operating conditions.

©

4-7

Loading...

Loading...