EX-TRAFIRE

®

125HD 10 Faults and troubleshooting

EN - 33

10 Faults and troubleshooting

Verify consumables selection according to:

17 FHT-EX

®

125TTH consumables for hand cutting torch on page EN-43

19 FHT-EX

®

125TTM consumables for machine cutting torch on

page EN-47

Contact your retailer or Thermacut

®

in the event of questions or

problems.

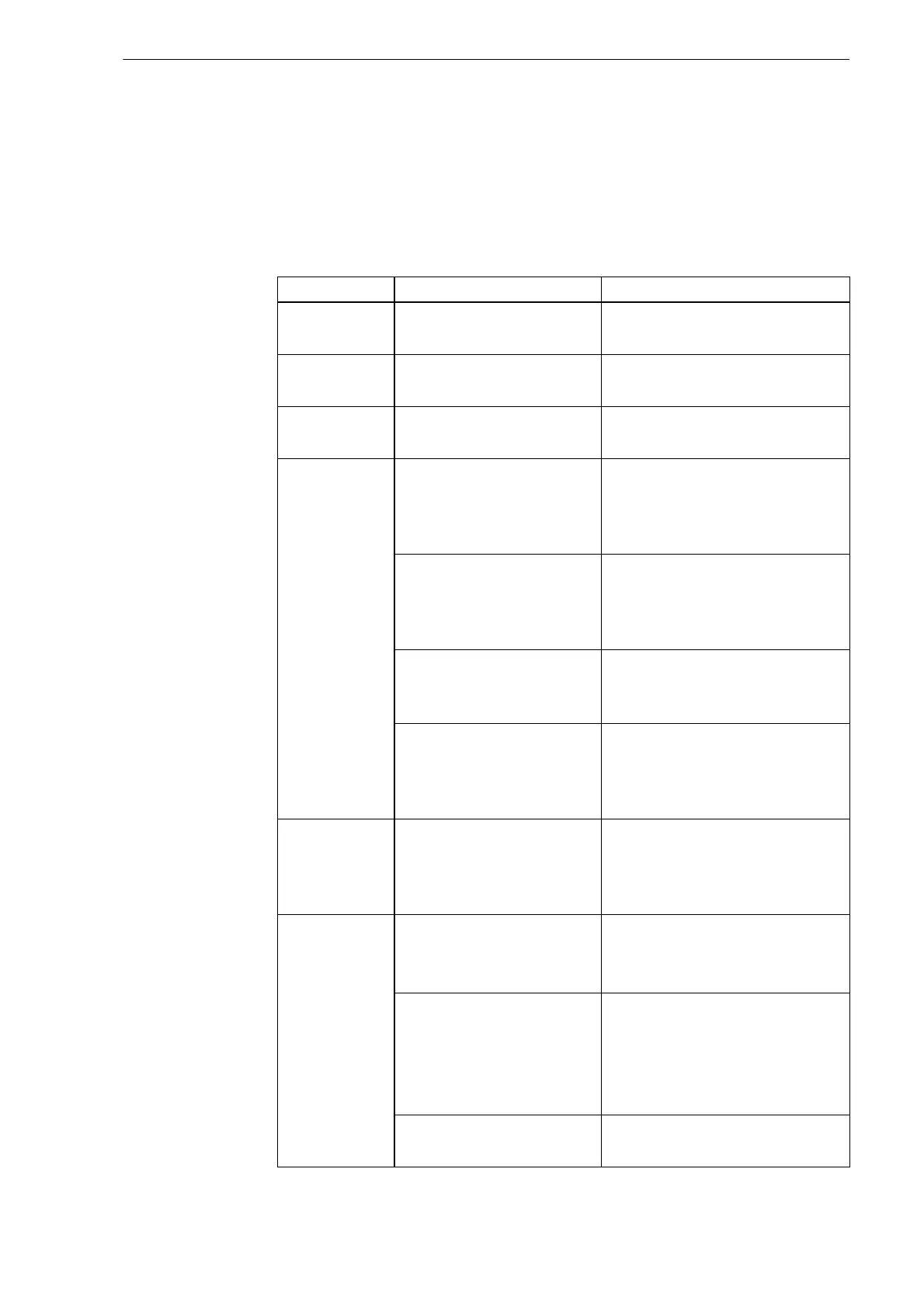

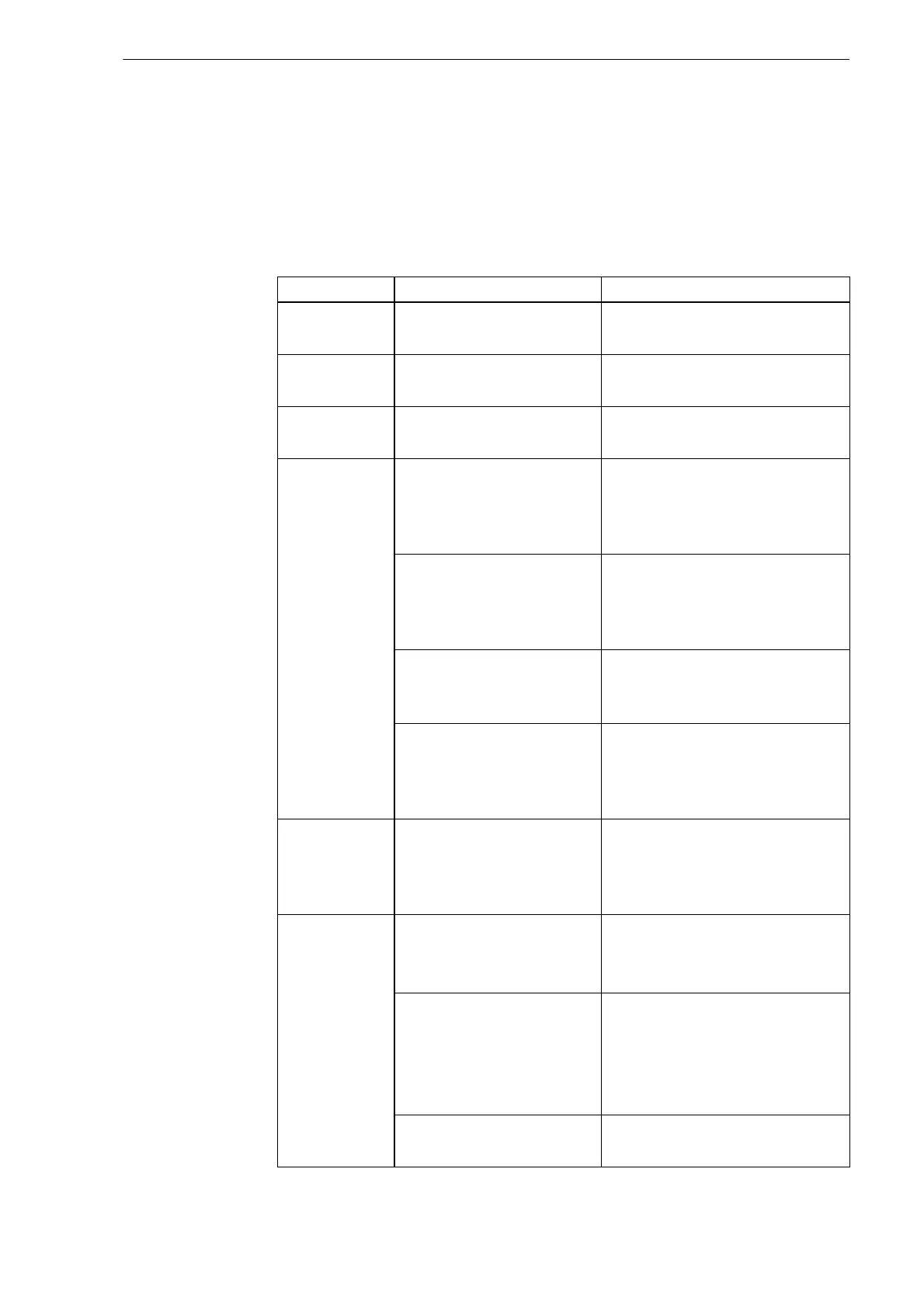

Table 12 Fault messages in the display

Error code Cause Troubleshooting

H01

Input power voltage is

too low.

Check the input power

voltage.

H02

Input power voltage is

too high.

Check the input power

voltage.

H03

No arc or current if the

trigger is pressed.

Check inverter, transformer,

and FRD.

H04

<Arc does not

ignite when

torch trigger

is pressed or

the CNC start

signal is on>

Missing nozzle or

electrode.

Check that the consumable

is installed correctly and, if

necessary, re-install it

correctly or replace it.

Dirt or short circuit in

the cutting torch.

Dismantle all consumables,

clean the inside of the

cutting torch and install

correctly.

Consumables are not

Thermacut

®

original

parts.

Use Thermacut

®

original

consumables.

Consumable part is

loose, incorrectly

installed or defective.

Verify that the consumables

are installed correctly and, if

necessary, re-install correctly

or replace them.

H05

The electrode is not

separated from the

nozzle during the

pilot arc.

Check for free movement of

the electrode and clean or

replace parts, if necessary.

H06

<Excess

temperature>

Fan is defective. Ensure that the fan is running

freely.

Replace the fan or fan motor.

Duty cycle has been

exceeded.

Switch off the

EX-TRAFIRE

®

125HD and

allow it to cool down.

Do not exceed the duty

cycle.

Components defective. Contact service or your

retailer.

Loading...

Loading...