EN - 36

10 Faults and troubleshooting EX-TRAFIRE

®

125HD

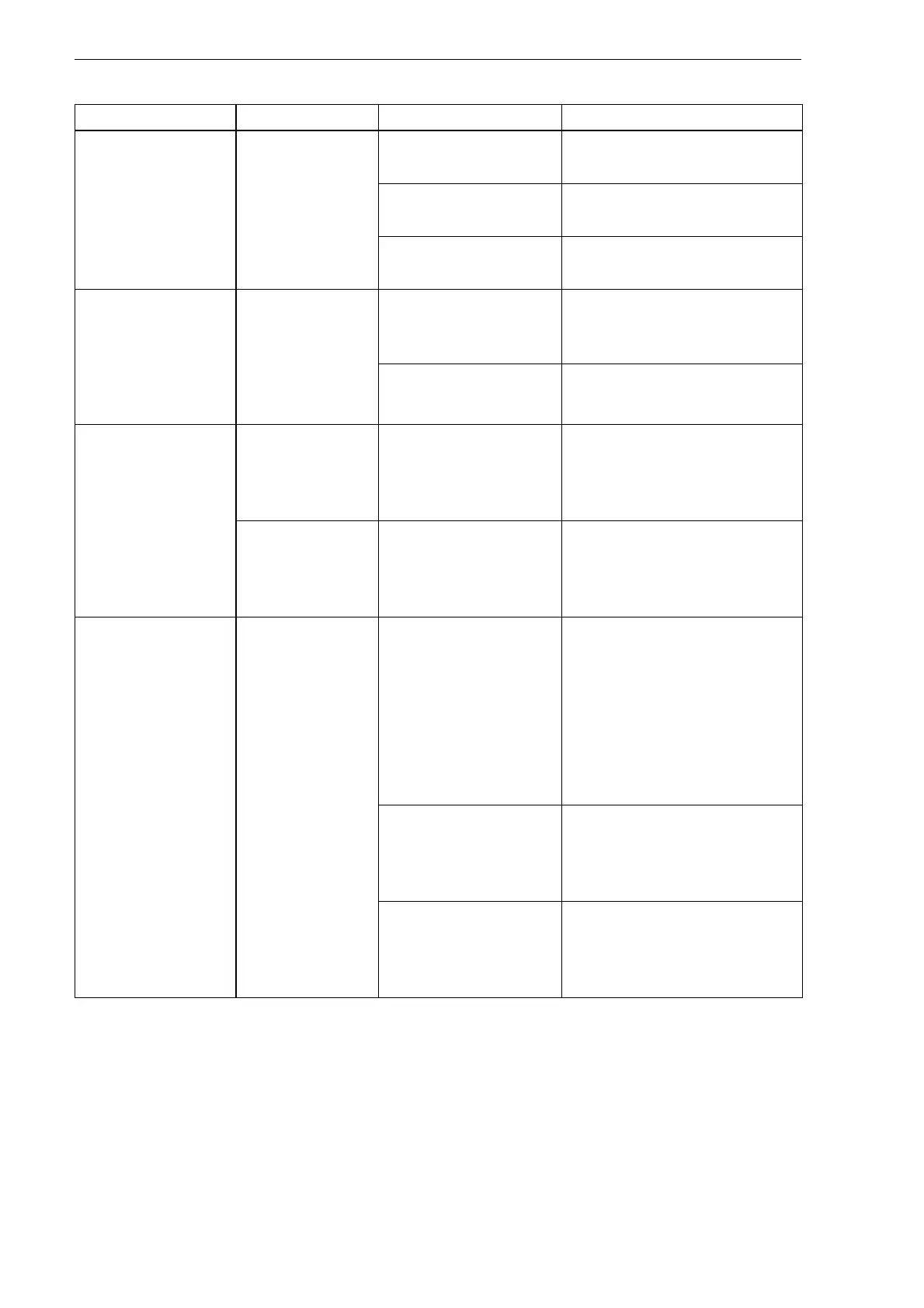

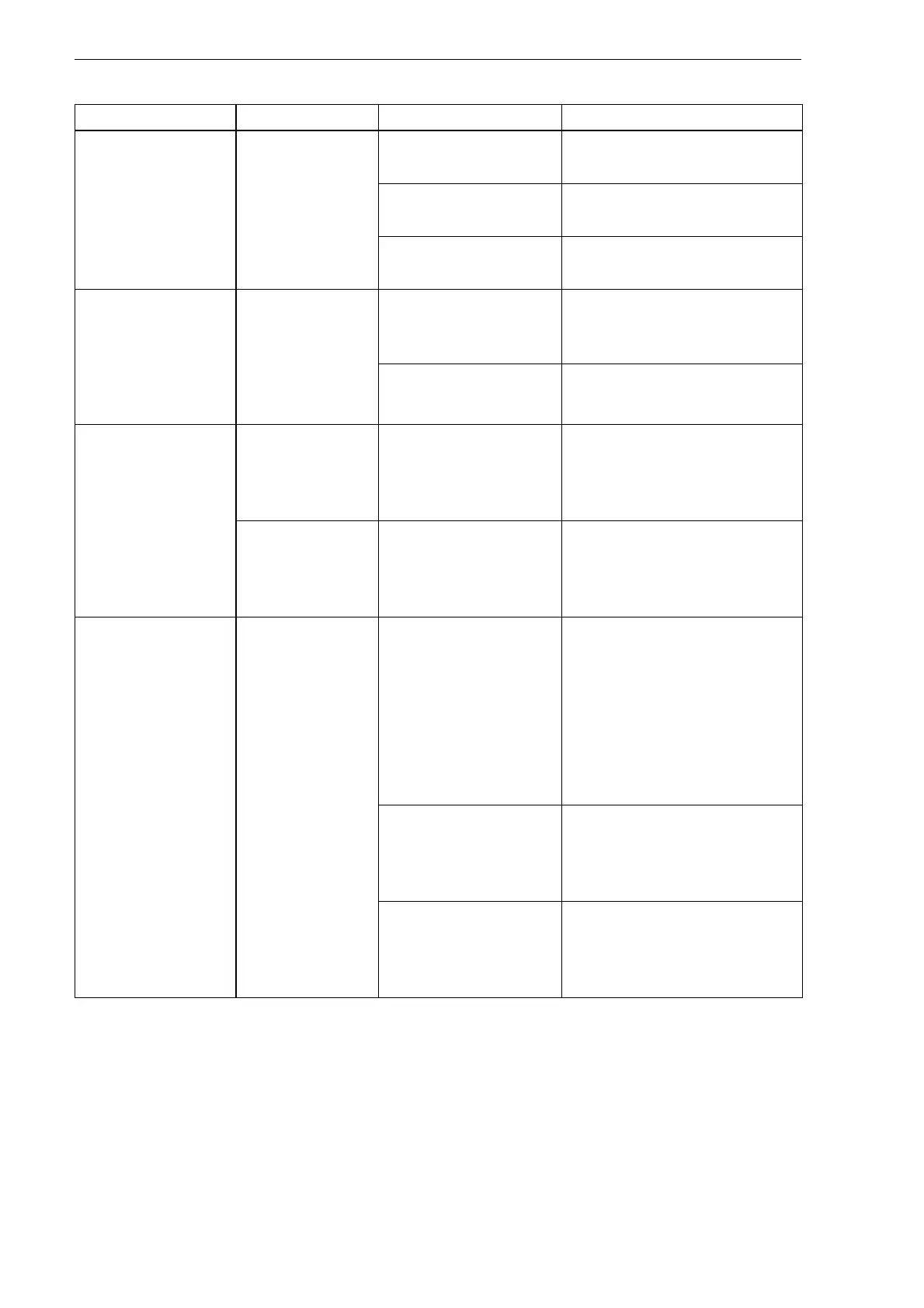

Table 13 General faults

Fault Description Cause Troubleshooting

Switch is set to ON,

LCD does not

illuminate.

No/low input

power

voltage.

Power supply is

insufficient.

Check the input power

voltage.

Power cable is not

connected.

Plug the input power plug

into the socket.

Switch is defective. Switch must be replaced by

an authorized professional.

Gas does not flow

when the torch

trigger is pressed

or the CNC start

signal is switched

on.

Gas valve

defective or

missing power

supply.

Cable to gas valve

loose or not

connected.

Contact your retailer.

Gas valve is

defective.

Contact your retailer.

Arc does not ignite

and there is no

fault code when

torch trigger is

pressed or the

CNC start signal is

on.

Incorrect

cutting torch

type is

connected.

Cutting torch type is

incorrect.

Verify the proper cutting

torch is connected.

Incorrect gas

pressure.

Consumables are

defective or

improperly

installed.

Check consumables and

replace, if necessary.

No transfer

between pilot arc

and workpiece.

Poor contact

between work

lead clamp

and

workpiece.

No contact between

work lead clamp

and workpiece.

Remove contamination

and/or oxidation from the

workpiece and the work

lead clamp.

Attach the work lead clamp

to the workpiece in order

to allow maximum

electrical conduction.

Distance between

cutting torch and

workpiece is too

great.

Decrease the distance

between cutting torch and

workpiece.

Work lead is

defective.

Have the work lead

checked and, if necessary,

replaced by an authorized

professional.

Loading...

Loading...