CUTMASTER 60i

Manual 0-5475 SERVICE

5-21

d. If all the LEDS now light there is a short at the other end of either the J302 or J303 harness. Plug them in

one at a time to determine which one is loading the Bias down.

i. J302 goes to the PFC board at J800 and the Inverter board at J610. Disconnect each of these in turn

and replace the board that was loading it down.

ii. J303 goes to the Inverter board. If J303 is loading the Bias down, disconnect the ribbon cables at J600,

the fan at J608, the current transducer at J601. If the unit is equipped with an Automation Interface

board disconnect its harness at J609.

iia. Now if any of the Bias supply LEDs are being loaded down replace the Inverter board.

Otherwise reconnect the removed connectors one at a time to find what component is causing

the problem and replace that.

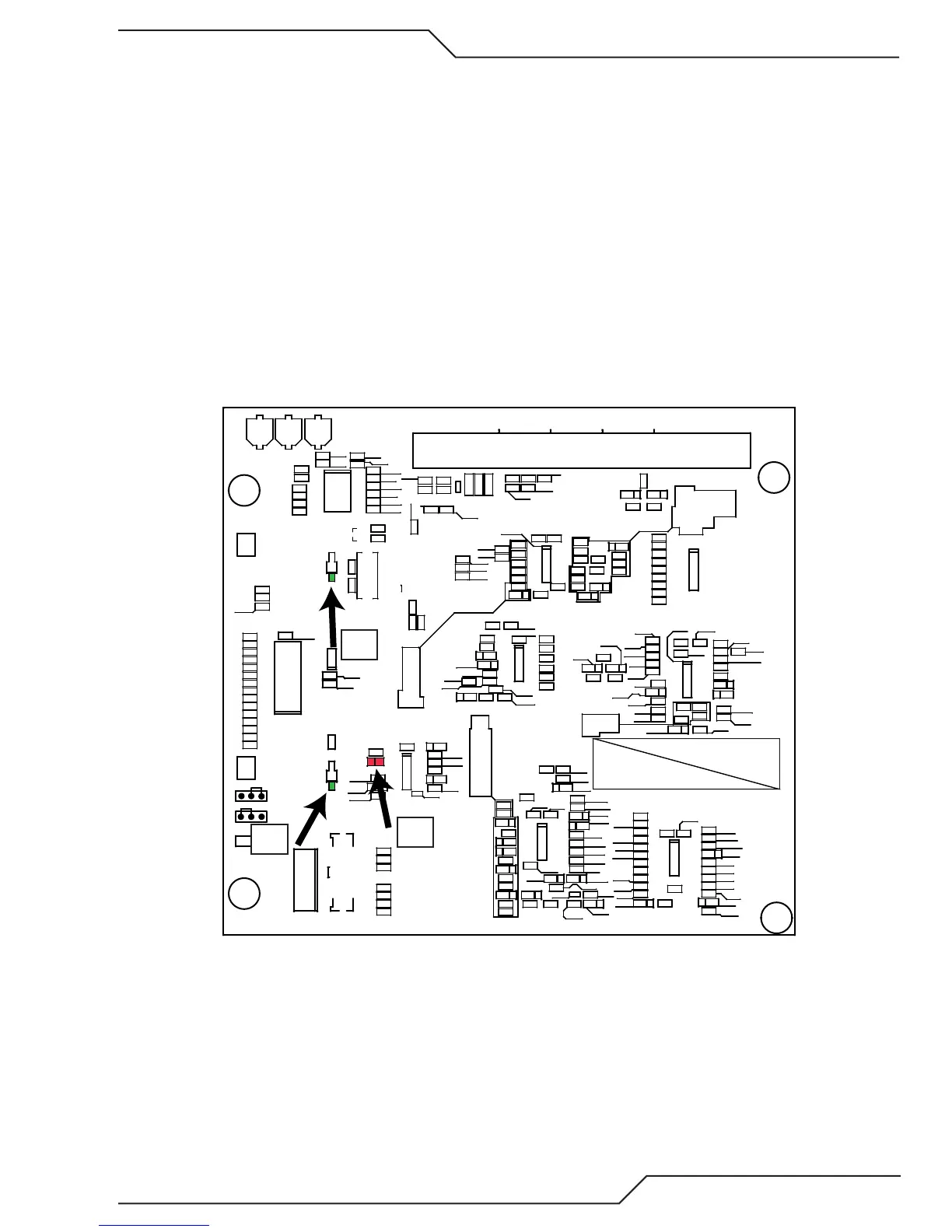

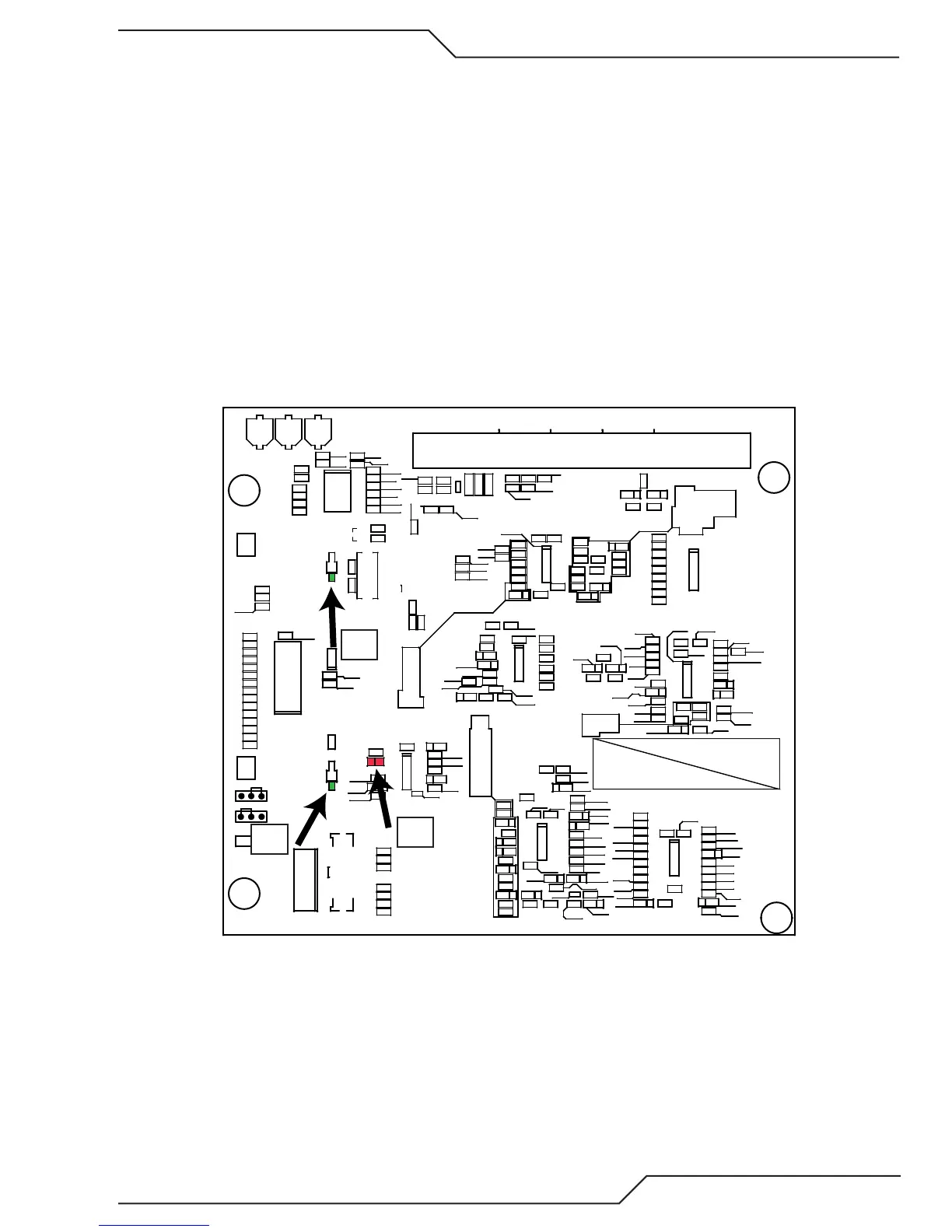

e. Control board LED D101 illuminated indicates +15V is supplied to the board and the blinking “Heartbeat”

LED, D135, indicates the microprocessor is operating.

f. If D101 does not light it may indicate +15V not getting to the board. If the display, front of the board, is

dark, measure for +15V at TP100_15V relative to TP1_GND on the back side of the Control & Display

board If +15V is present it may be only the LED is defective.

GND

15V

APPLY RTV TO COMPLETELY COVER PINS IF NEEDED

GREEN

YELLOW

ORANGE

RED

BROWN

BLACK

C

C

C

C

C

GND

OPEN

START

ISP

PROG

NORM

1

1

TP100_

TP1_

R268

R267

R265

D135

R175

C139

C168

C136

C138

+

C115

C171

+

C117

C142

C135

C151

C134

C146

C153

C161

C112

C160

C172

C130

C129

C173

C167

C158

C163

C164

C165

C169

C170

C143

C152

C150

C149

C109C107

C166

C156

C162

C159

C157

C120

+

C116

C124

C132

C118

C125

C122

C121

C126

C119

C123

C148

C108

C104

C106

C110

C127

C128

C144

C140

C141

C145

C147

C154

C155

D148

D169

D147

D101

D177

D146

D144

D152

D151

D165

D154

D167

D173

D174

D168

D170

D163

D164

D157

D166

D175

D172

D176

D171

D153

D155

D156

D149

D150

D161

D159

D162

D158

1

J102

1

J101

L102

1

502

49

J100

1

J103

R242

R231

R233

R253

R161

R167

R238

R162

R158

R266

R256

R187

R153

R192

R180

R154

R145

R208

R193

R185

R209

R206

R183

R205

R228

R203

R197

R230

R227

R223

R264

R144

R147

R138

R240

R152

R243

R261

R255

R150

R139

R211

R177

R176

R226

R224

R218

R236

R220

R234

R251

R263

R229

R232

R258

R259

R241

R260

R262

R254

R252

R182

R181

R178

R189

R196

R210

R170

R173

R199

R202

R190

R194

R169

R113

R112

R107

R108

R109

R257

R155

R160

R163

R111

R237

R215

R239

R110

R216

R235

R221

R219

R222

R217

R122

R121

R140

R137

R213

R149

R143

R146

R151

R165

R148

R135

R131

R120

R123

R132

R126

R125

R124

R130R129

R127

R133

R128

R136

R134

R168

R166

R201

R204

R250

R249

R248

R245

R244

R164

R214

R171

R198

R172

R184

R188

R207

R212

R174

R200

R247

R246

R179

R195

R186

R191

1

U113

1

U111

1

U106

1

33

U102

U101

1

U107

1

U114

1

U112

1

U104

1

U108

1

U110

1

U109

Y100

C174

D178

D179

D159

D101

D135

i. +15V comes over the ribbon cable from the Inverter board. If no +15V and no display on the Control

board remove the ribbon cable from the Control & Display board and measure for +15V on the end

of the disconnected ribbon cable at pins 5 & 6 with ground on any of pins 2, 4, 8, or 10 of the ribbon

cable connector. You will need a small probe, no more than 0.025” dia. A paper clip is too big and can

damage the connector.

Loading...

Loading...