3-14

Axle Installation (cont’d)

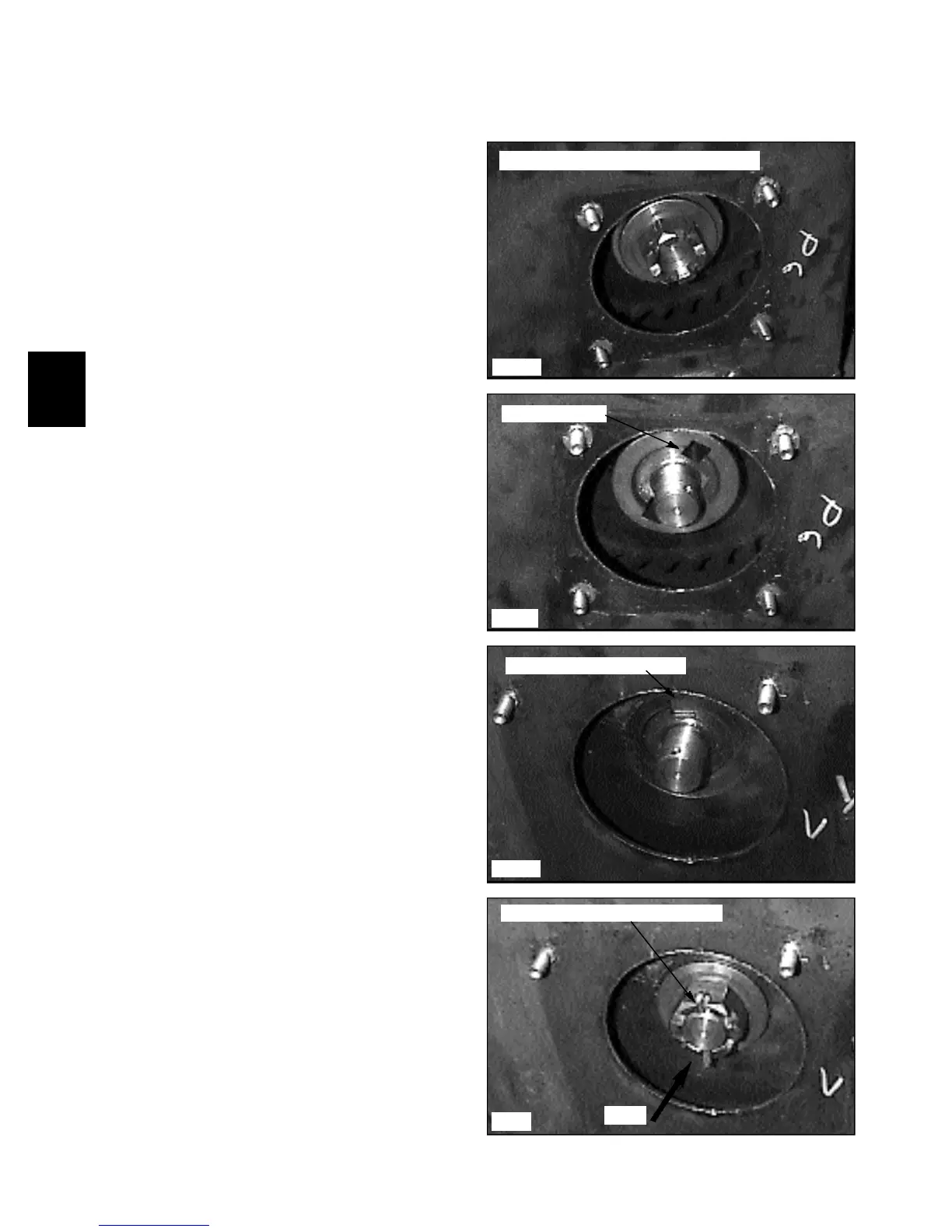

14 Place the axle washer and castle nut onto the threaded

end of the axle. (fig. C2434) Lightly tap the face of the

axle flange, while holding the sprocket in position, if nec-

essary to get the axle washer on and the castle nut started.

15 Hold the axle from rotating and tighten the castle nut

and guide the axle into the final drive housing as straight

as possible to prevent damaging the seal. Tap the axle

flange with a hammer if necessary to assist the installa-

tion.

As the castle nut is being tightened the rear (inside)

bearing is being pressed into place and the axle oil seal

is simultaneously pulled into the proper location into

the final drive housing.

16 When the castle nut will not turn on any further tap

the face of the axle flange with a hammer to ensure the

seal, bearings and races have seated into place.

17 Remove the castle nut, axle washer and remove the

axle oil seal installation tools.

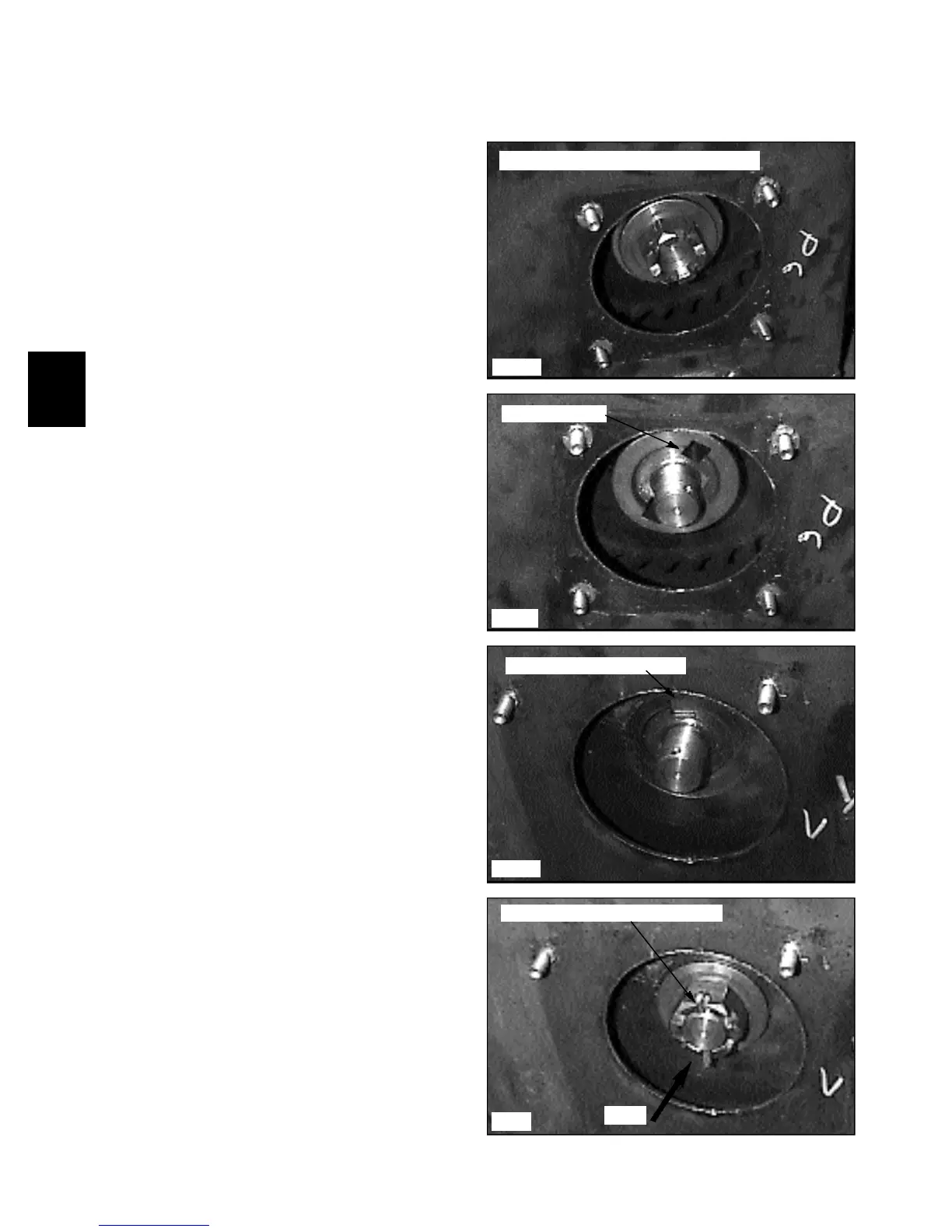

18 Line up the axle and sprocket key ways and install

the keys into the key way slots. (fig. C2435) Use a brass

drift punch and hammer if necessary to install the keys

into the key way slots. (fig. C2436).

19 Install the axle washer and castle nut. Tighten the

castle nut to remove all axle bearing end play. (Zero pre-

load). Continue tightening until the split pin hole in the

axle will align with the castle nut slot.

20 Install the split pin. Bend both ends of the split pin

straight back against the axle washer. (fig. C2431).

21 Install the axle cover using silicone to seal the mat-

ting surfaces. Do not over tighten the retaining nuts. 12

lbs/ft maximum. (16.5 nm).

22 Install the drive chain. Refer to Section 3.3.

23 Fill the final drive housing to the correct level using

10W30 API classification SE/ CD oil. Refer to Section

3.2 for procedure.

24 Install the inspection cover using silicone to seal the

matting surfaces. Do not over tighten the retaining nuts.

12 lbs/ft maximum. (16.5 nm).

25 Install the wheels. Torque the wheel nuts to 100 to

110 lbs/ft. (135 to 149 nm).

AXLE ASSEMBLY 3.5

C2434

C2435

C2436

C219

Place washer on axle and start castle nut

Align key ways

Axle sprocket keys installed

Bend split pin against axle washer

Bend

Loading...

Loading...