ServicingtheEngine-Cooling

System

ServiceInterval:Every100hours—Inspectthe

cooling-systemhoses.

Every2years—Flushthecoolingsystemandreplace

uid.

Beforeeachuseordaily(moreoftenindustyordirty

conditions).

1.Shutofftheengineandraisethehood.

2.Cleantheengineareathoroughlyofalldebris.

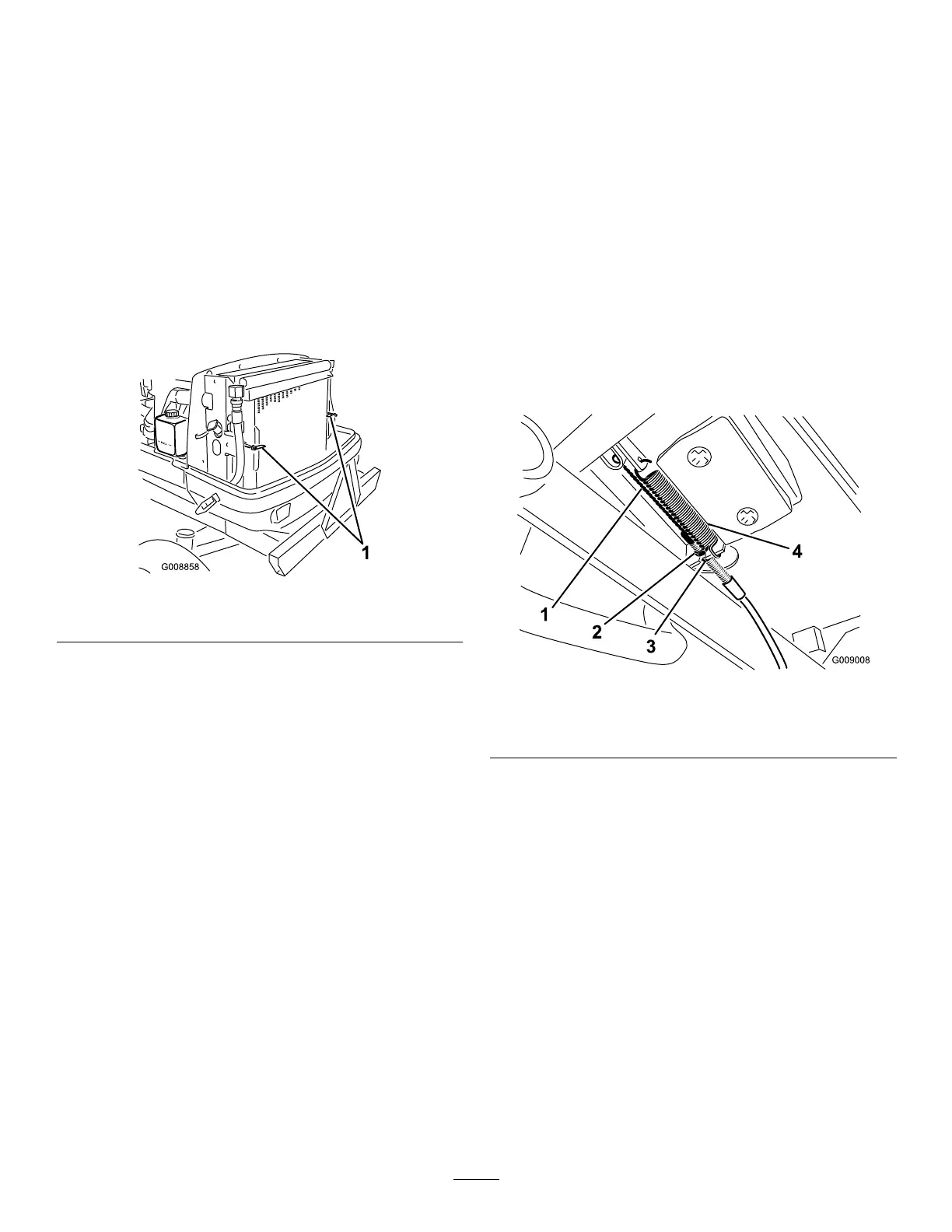

3.Rotatethelatchessecuringtheoilcoolertotheframe

(Figure78).

Figure78

1.Latches

4.Pivottheoilcoolerrearward.

5.Cleanbothsidesoftheoilcoolerandradiatorarea

thoroughlywithcompressedair.

Note:Startfromthefansideandblowthedebrisout

towardstheback.Thencleanfromthebacksideand

blowtowardsthefront.Repeatprocedureseveraltimes

untilallchaffanddebrisisremoved.

Important:Cleaningtheradiatororoilcooler

withwatercanpromoteprematurecorrosionand

damagetocomponents.

6.Pivottheoilcoolerbackintoposition.

7.Securetheoilcoolertotheframewiththelatchesand

closethehood.

BrakeMaintenance

AdjustingtheServiceBrakes

Adjusttheservicebrakeswhenthereismorethan50mm(2

inches)of“freetravel”ofthebrakepedalorwhenthebrakes

donotworkeffectively.Freetravelisthedistancethebrake

pedalmovesbeforeyoufeelbrakingresistance.

1.Disengagethelockinglatchfromthebrakepedalsso

thatbothpedalsworkindependentlyofeachother.

2.Toreducethefreetravelofthebrakepedals,adjust

thebrakecablesasfollows:

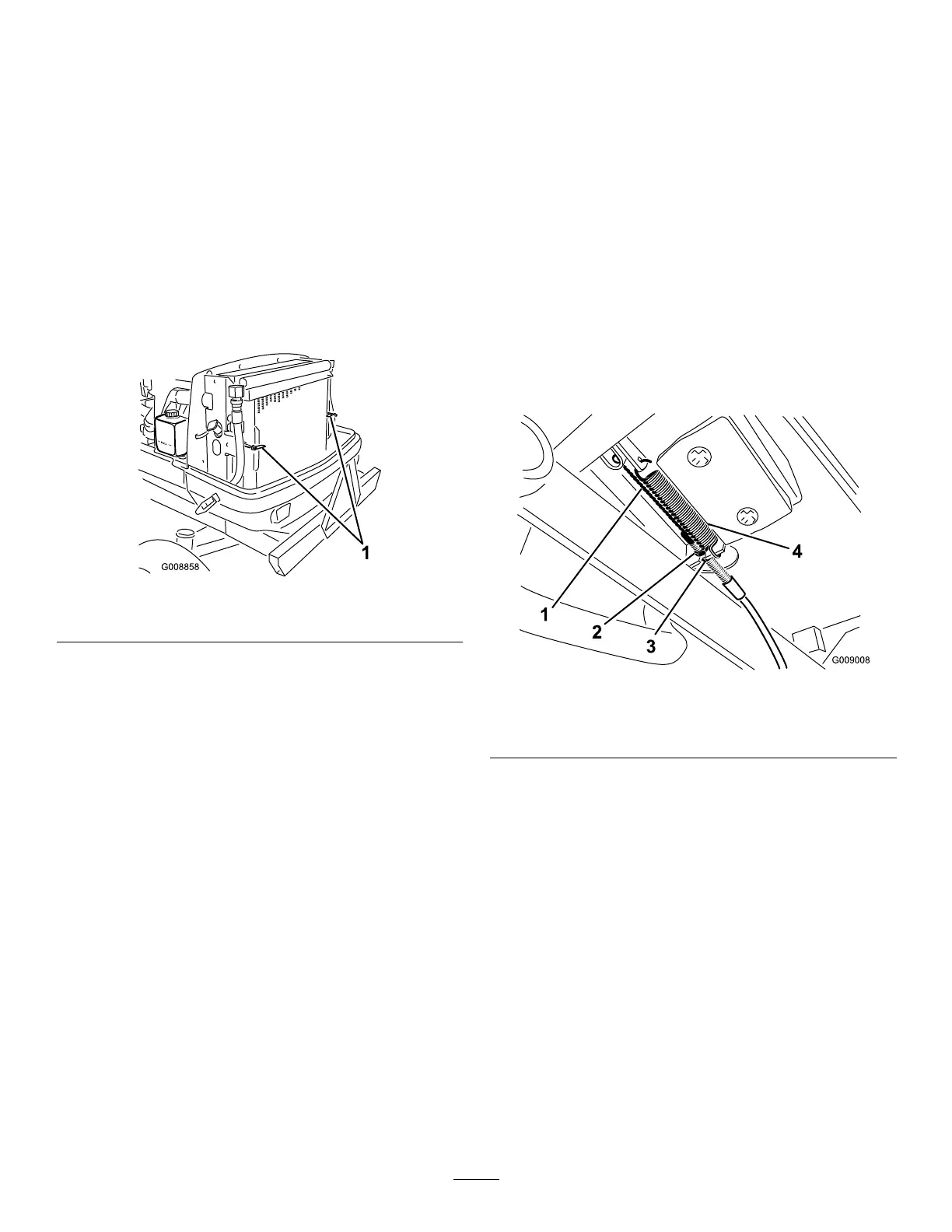

A.Loosenthefrontnutonthethreadedendofthe

brakecable.

Note:Foreasieraccesstotheadjustingnuts,you

mayunhookandremovethespring.

Figure79

1.Brakecable3.Rearnut

2.Frontnut

4.Spring

B.Tightentherearnutuntilthebrakepedalshave

50mm(2inches)offreetravel.

C.Repeattheprocedureontheotherbrakecable.

D.Tightenthefrontnutsafteradjustingthebrakes.

E.Installthesprings,ifremoved.

Important:Adjustingthebraketensiontootight

decreasesthelifeofthefriction-padmaterial.

52

Loading...

Loading...