Premaintenance

Procedures

CAUTION

Raisingthemachineforserviceormaintenance

relyingsolelyonmechanicalorhydraulicjacks

couldbedangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunctionallowingthemachinetofall,which

couldcauseinjury.

Donotrelysolelyonmechanicalorhydraulicjacks

forsupport.Useadequatejackstandsorequivalent

support.

PreparingfortheMachinefor

Maintenance

Performthefollowingbeforeservicing,cleaning,ormaking

anyadjustmentstothemachine.

1.Movethemachinetoalevelsurface.

2.Shutofftheengine,settheparkingbrake,waitforall

movingpartstostop.

3.Removethekeyfromthekeyswitch.

Lubrication

LubricatingtheGreaseFittings

ServiceInterval:Every100hours

Greasetype:NationalLubricatingGreaseInstitute(NGLI)

grade#2multi-purposegungrease.

Note:Refertothelubricationchartforthegreasepoints

andserviceintervals.

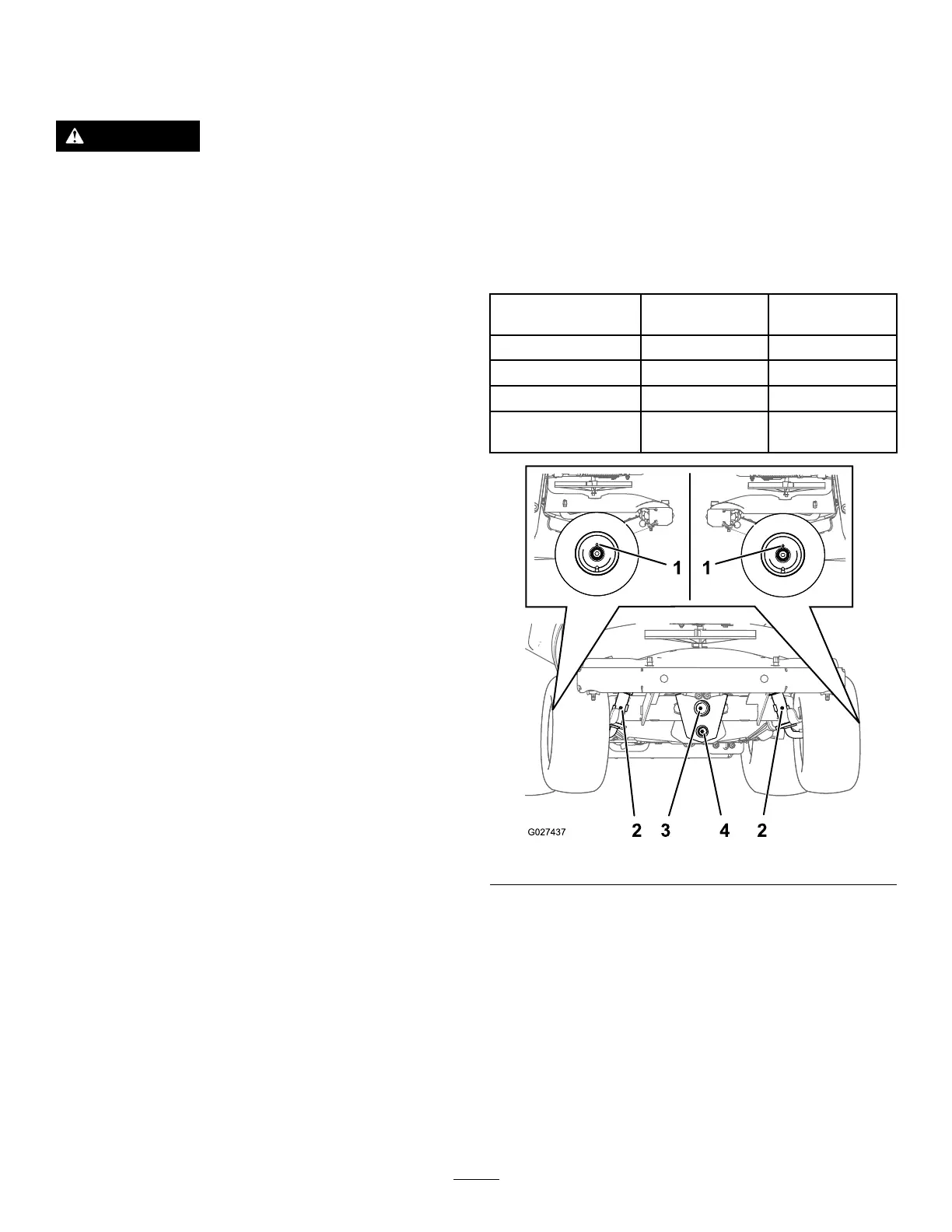

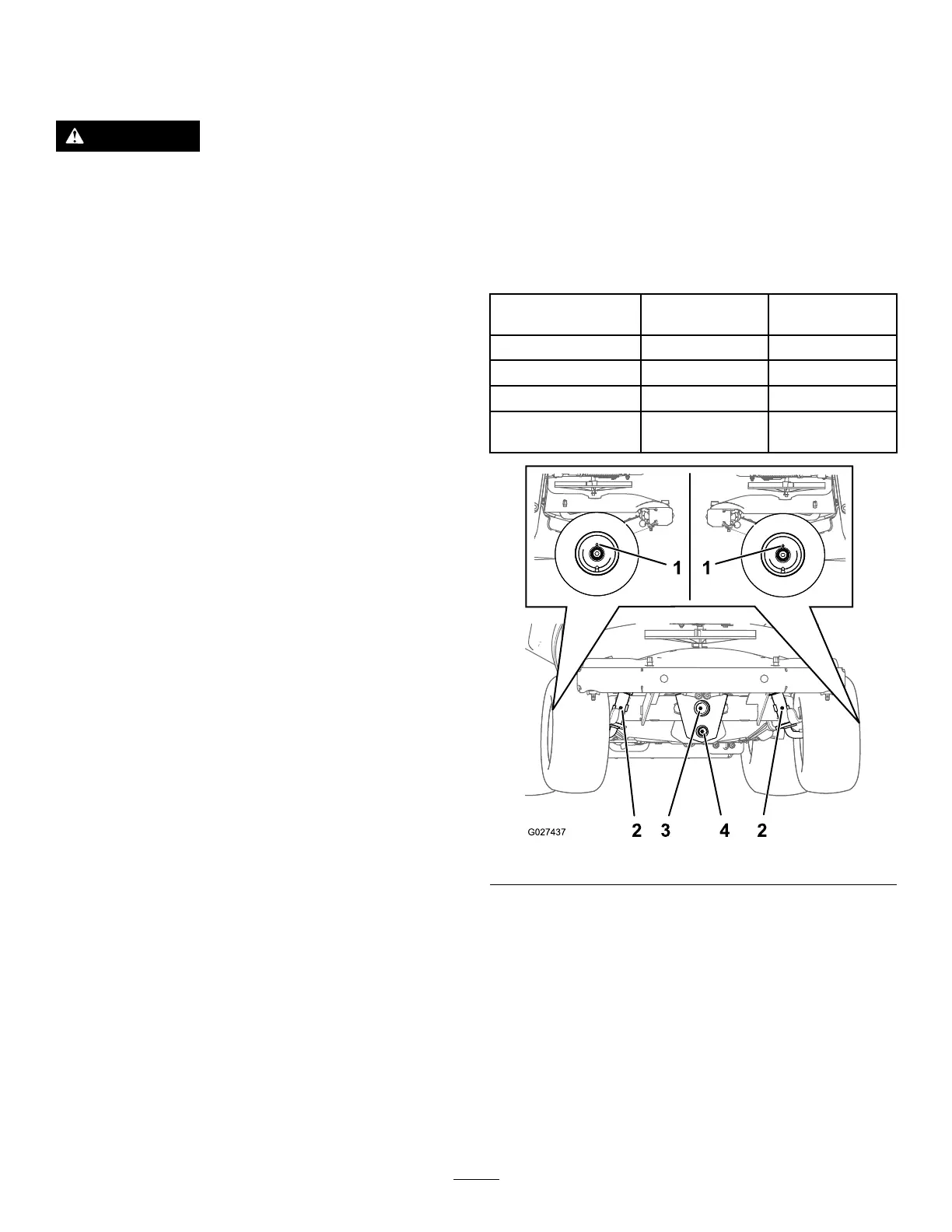

LubricationChart

FittingLocationsInitialPumps

Numberof

Places

1.Wheelbearings1to22

2.Kingpinpivots1to22

2.Frontaxlepivots1to21

3.Steeringcontrol

pivot

1to21

Figure57

1.Shutoffengine,settheparkingbrake,waitforall

movingpartstostop,andremovekey.

2.Wipecleanthegreasettingswitharag(Figure57).

3.Connectagreaseguntothetting(Figure57).

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

49

Loading...

Loading...