DriveSystem

Maintenance

CheckingtheAirPressurein

theTires

ServiceInterval:Every50hours

Note:Boththefrontandreartiresneedtobeinated.

1.Stoptheengine,settheparkingbrake,removethekey,

andwaitforallmovingpartstostopbeforeleavingthe

operatingposition.

2.Checktirepressureinfrontandreartires.

3.Ifnecessary,adjusttheairpressureinthetiresto83

to97kPa(12to14psi).

TorquingtheAxleBolts

ServiceInterval:Yearly

1.Torquethe4axleboltsonbothfrontandrearwheels

(Figure76)to48N∙m(35ft-lb).

2.Torquethe2setscrewsoneachrearwheelsto12N∙m

(105in-lb).

Important:Ifyouremovethewheel(s)formaintenance,

applymedium-gradethread-lockingcompoundtothe

threadsoftheboltsbeforeinstallingthewheel(s)

Important:Ifyouremovetherearwheel(s)for

maintenance,applyacopper-based,anti-seizing

compoundontherear-axleshafts.

Important:Donotuseanti-seizecompoundonthe

wheelbolts.

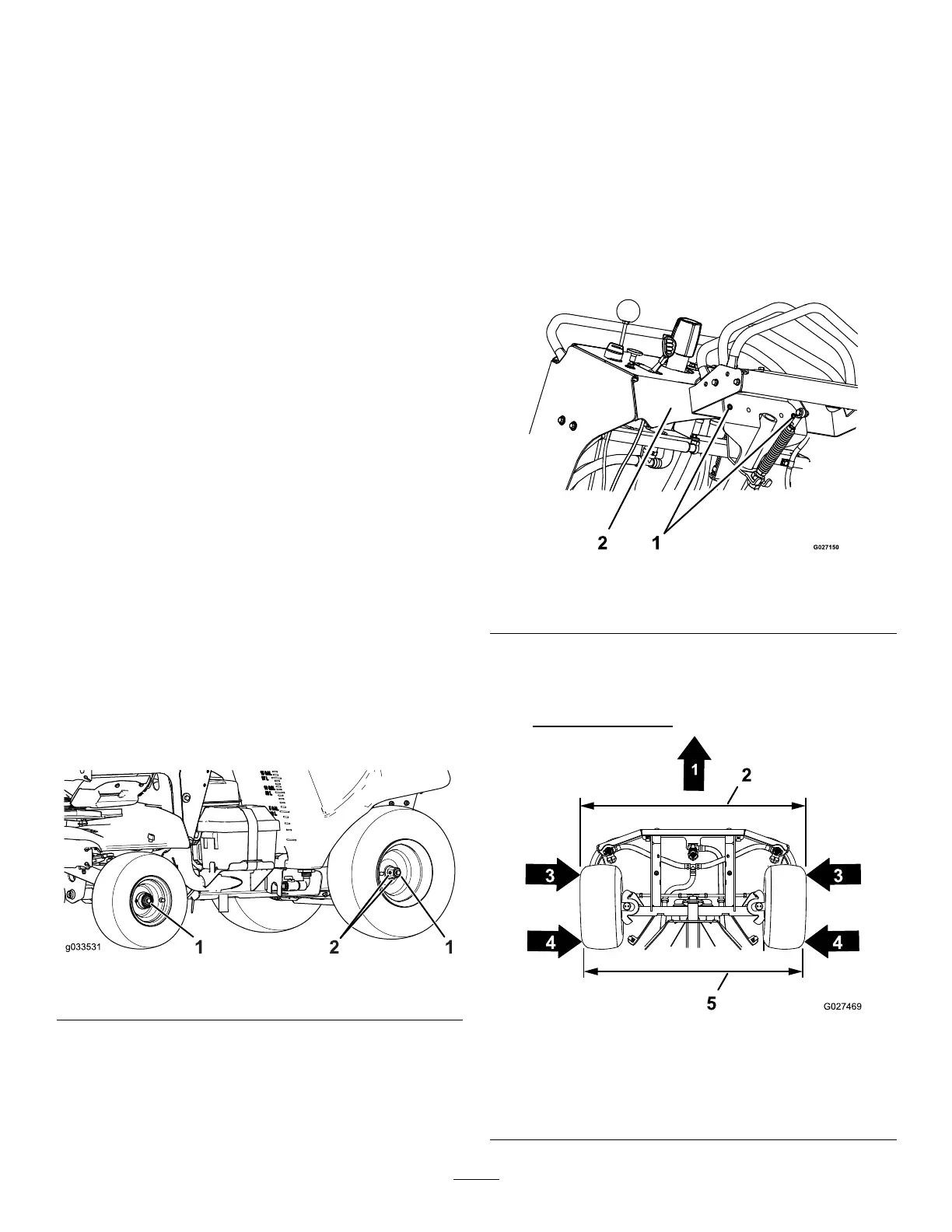

Figure76

1.Axlebolts

2.Setscrews

AligningtheFrontWheels

Operatorsuppliedequipment:2bolts9x76mm(5/16x

3inch)orlonger

1.Shutofftheengine,settheparkingbrake,removethe

key,andwaitforallmovingpartstostopbeforeleaving

theoperatingposition.

2.Checkthetirepressure;refertoCheckingtheAir

PressureintheTires(page60).

3.Centerandsecurethesteeringcontrolbyaligning2

bolts(5/16x3inch)throughtheoutsideholesonthe

steeringcontrolandthroughthecontrolcolumn.

Figure77

1.Outsideholes(steering

control)

2.Controlcolumn

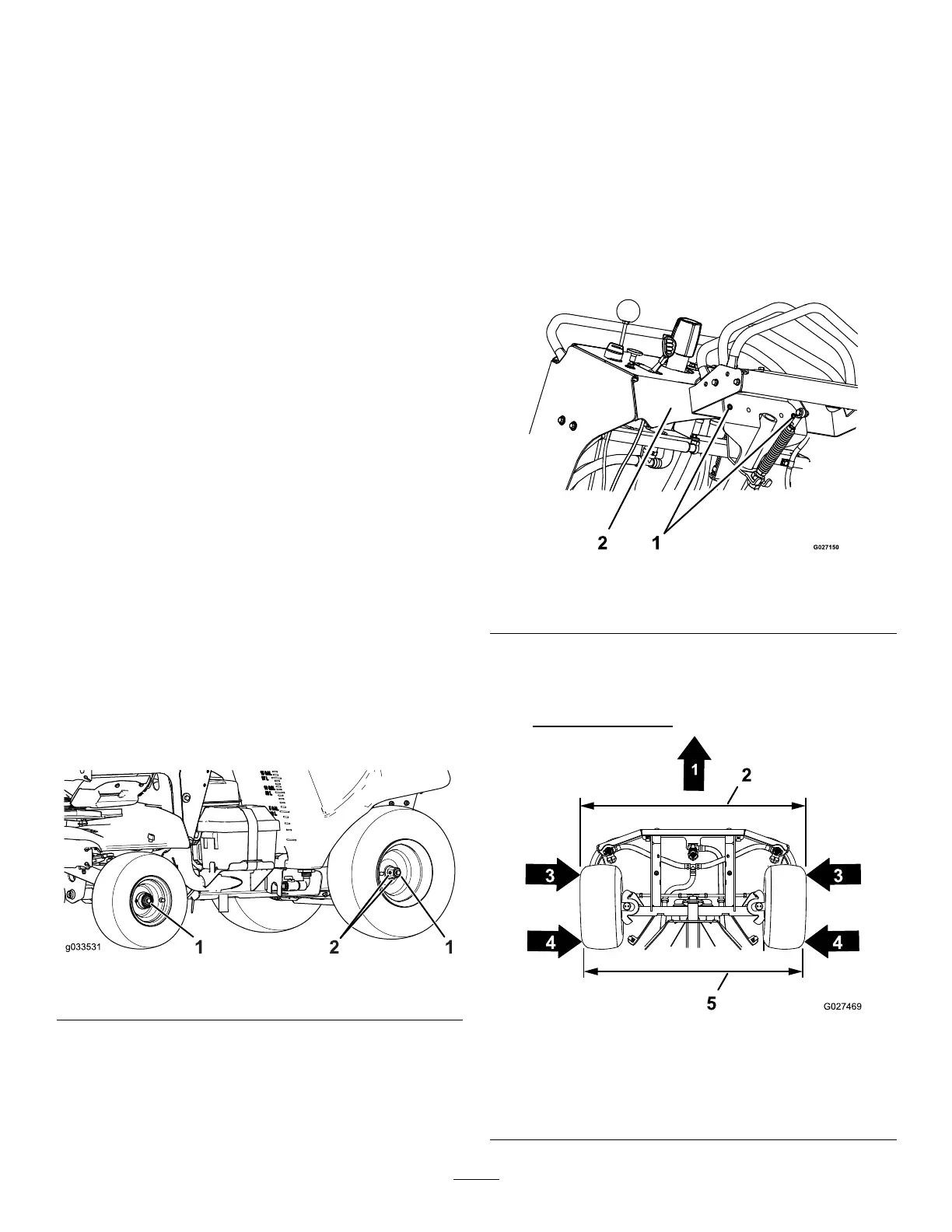

4.Measurethedistancebetweenthe2frontfacesofthe

fronttiresasshowninFigure78.

Recordthefrontmeasurementhere

.

Figure78

Viewedunderneathmachine

1.Frontofthemachine4.Rearfaceofthetire

2.Frontmeasurement5.Rearmeasurement

3.Frontfaceofthetire

60

Loading...

Loading...