CheckingforBentBlades

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKEDposition,andset

theparkingbrake.

2.MovethethrottlelevertotheSLOWposition,

stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingthe

operatingposition.

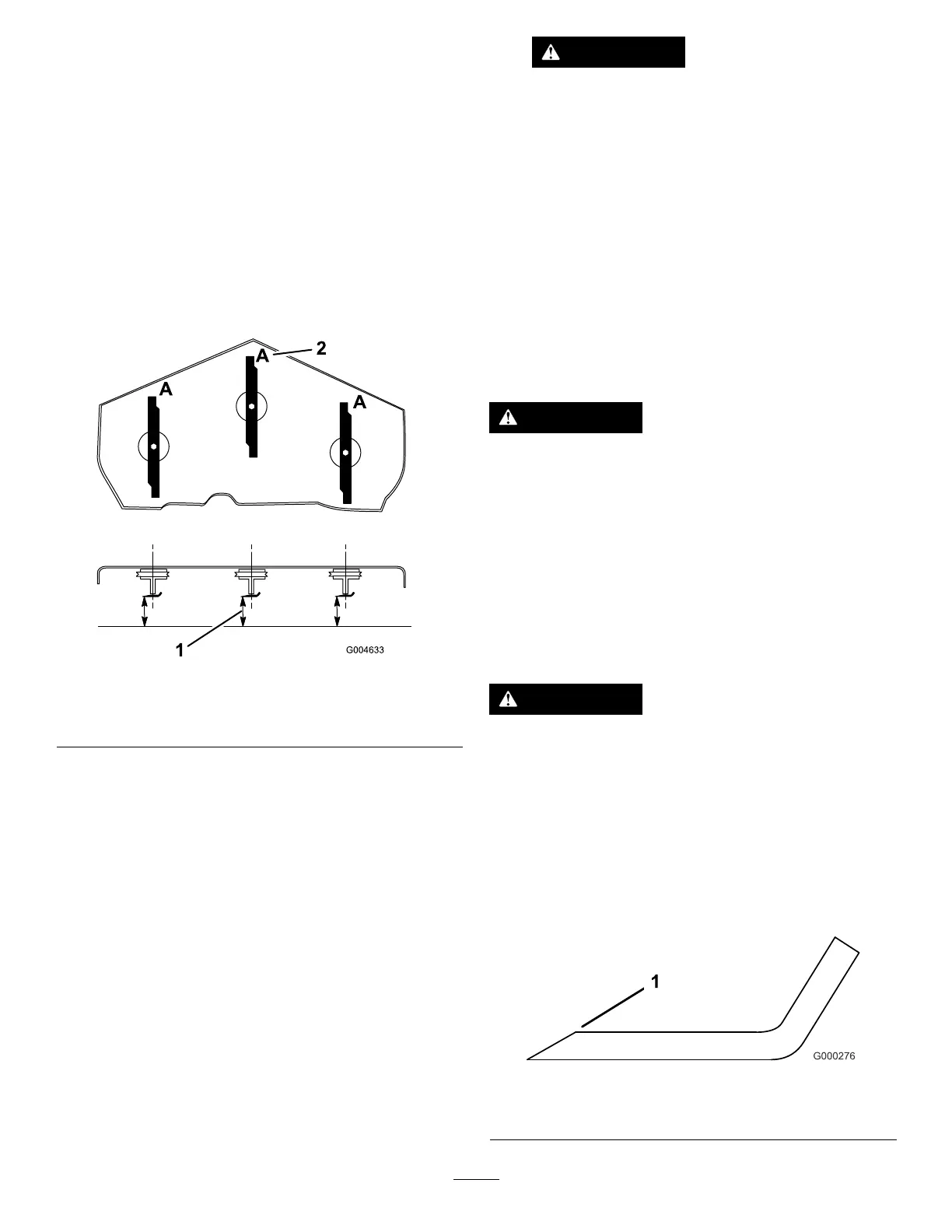

3.Rotatethebladesuntiltheendsfaceforward

andbackward(Figure94).

Note:Measurefromalevelsurfacetothe

cuttingedge,positionA,oftheblades(Figure

94).Notethisdimension.

g004633

Figure94

1.Measureherefromblade

tohardsurface.

2.PositionA

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedge

ofthebladesatthesamepositionasinstep3

above.

Note:Thedifferencebetweenthedimensions

obtainedinsteps3and4mustnotexceed

3mm(1/8inch).Ifthisdimensionexceeds

3mm(1/8inch),thebladeisbentandmustbe

replaced;refertoRemovingtheBlades(page

70)andInstallingtheBlades(page71).

WARNING

Abladethatisbentordamagedcould

breakapartandcouldseriouslyinjureor

killyouorbystanders.

•Alwaysreplacebentordamaged

bladewithanewblade.

•Neverleorcreatesharpnotchesin

theedgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.Toensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

WARNING

Contactwithasharpbladecancauseserious

injury.

Wearglovesorwrapsharpedgesoftheblade

witharag.

1.Holdthebladeendusingaragorthickly-padded

glove.

2.Removethebladebolt,anti-scalpplate,and

bladefromthespindleshaft(Figure97).

SharpeningtheBlades

WARNING

Whensharpeningablade,piecesoftheblade

couldbethrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

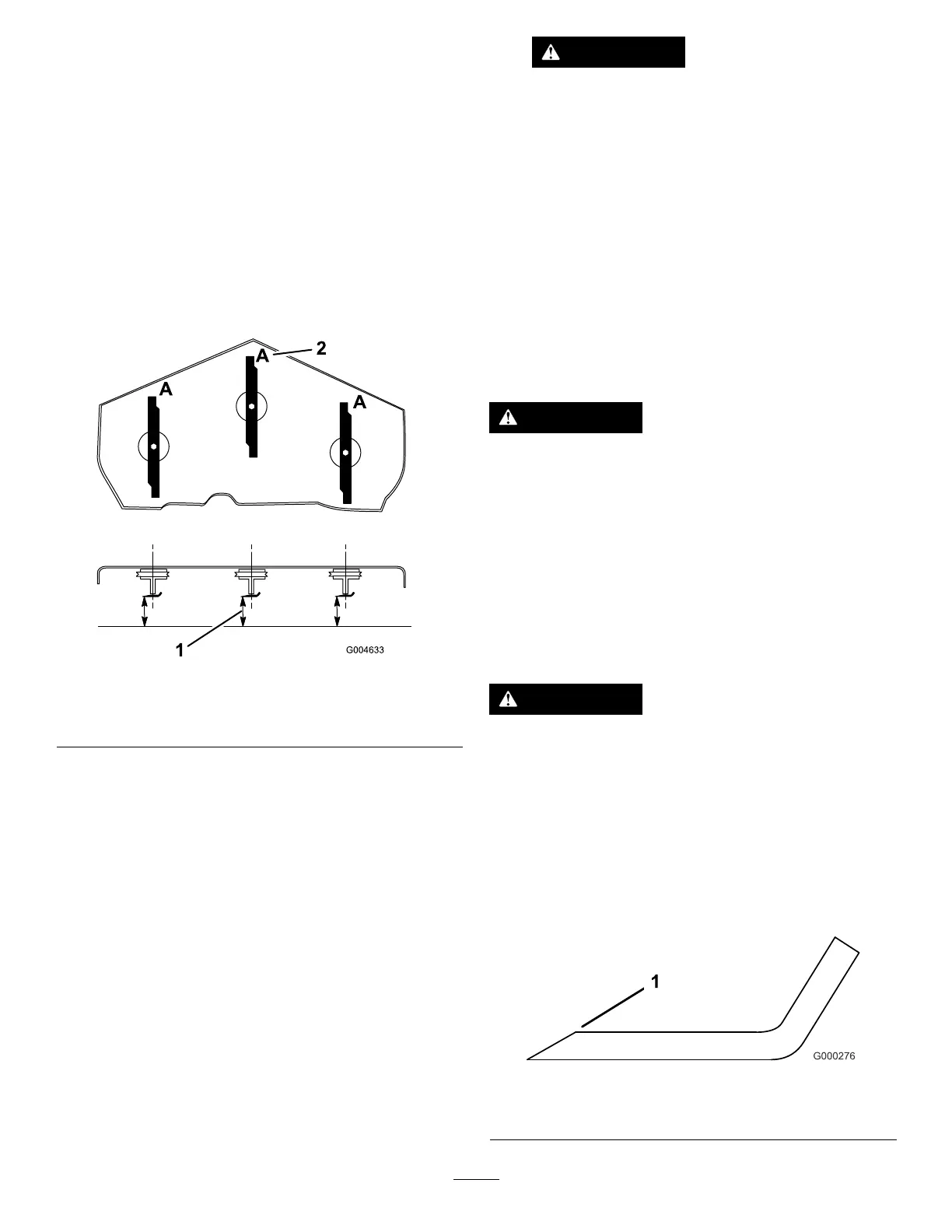

1.Sharpenthecuttingedgeatbothendsofthe

blade(Figure95).

Note:Maintaintheoriginalangle.Theblade

retainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

g000276

Figure95

1.Sharpenattheoriginalangle

70

Loading...

Loading...