Setup

MediaandAdditionalParts

Description

Qty.

Use

Starterkey

2

Operator'sManual

1

Engineowner'smanual1

PartsCatalogInstructionCard

1

Operatortrainingmaterials

1

Screenlter

2

Readthemanualsandwatchthetrainingmaterialsbefore

operatingthemachine.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Ifyouhavequestionsorneedadditionalinformationregardingthespraycontrolsystem,refertothe

Operator’sManualsuppliedwiththesystem.

Important:Thissprayerissoldwithoutspraynozzles.

Tousethesprayer,youmustobtainandinstallthenozzles.ContactyourauthorizedTorodistributorfor

informationontheavailablesectionkitandaccessories.

Afteryouinstallyournozzlesandbeforeusingthesprayerforthersttime,adjustthesectionbypass

valvessothatthepressureandapplicationrateremainsthesameforallsectionswhenyouturn1or

moresectionsoff.RefertoCalibratingtheSection-BypassValves(page28).

1

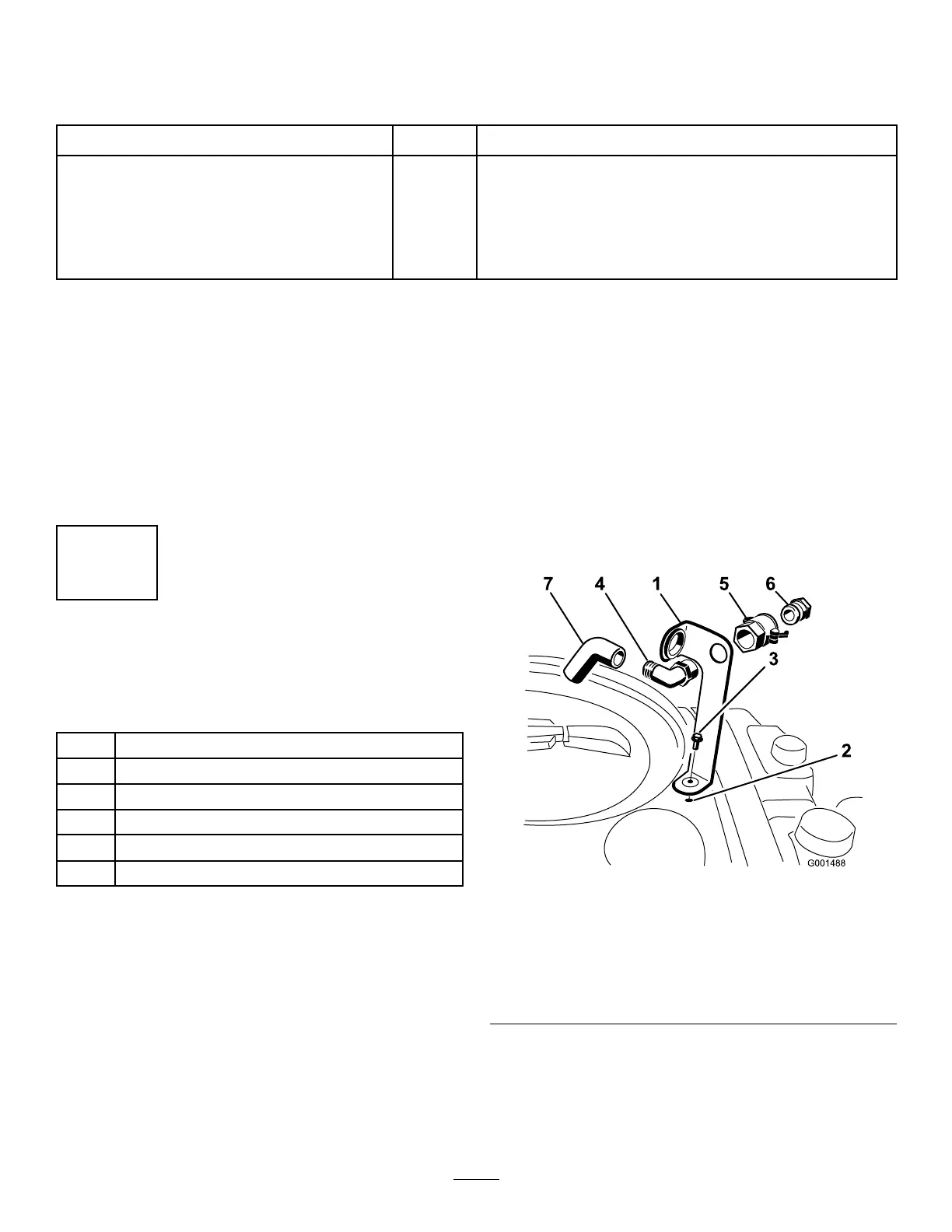

InstallingtheAnti-Siphon

FillReceptacle

Partsneededforthisprocedure:

1

90°tting

1

Quickcoupler

1Hoseadapter

1Fill-receptaclebracket

1

Flange-headbolt(5/16x3/4inch)

1Anti-siphonhose

Procedure

1.Placethell-receptaclebracketoverthe

threadedholeinthetankandsecureitwitha

ange-headbolt(5/16x3/4inch)asshownin

Figure3.

g001488

Figure3

1.Fill-receptaclebracket

5.Quickcoupler

2.Threadedholeinthetank6.Hoseadapter

3.Flangebolt(5/16x3/4

inch)

7.Anti-siphonhose

4.90°elbowtting

2.Placethethreadedendofthe90°elbowtting

throughthebracketandthreadthequickcoupler

ontoit,securingittothebracket(Figure3).

Note:Installthettingwiththeopenend

pointingtowardthelargeopeninginthebracket

12

Loading...

Loading...