BreakinginaNewMachine

ServiceInterval:Aftertherst100hours—Toprovide

properperformanceandlong

sprayerlife,followtheseguidelines

fortherst100operatinghours:

•Checktheengine-oilanduidlevelsregularly

andbealertforindicationsofoverheatinginany

componentofthesprayer.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeaccelerating.

•Tooptimizethebrakesystem,burnish(breakin)

thebrakesasfollows:

1.Load454L(120USgallons)ofwaterinto

thetank.

2.Movethemachinetoanopen-levelarea.

3.Drivethemachineatfullspeed.

4.Applythebrakesrapidly.

Note:Stopthemachineinastraightline

withoutlockingupthetires.

5.Wait1minutetoallowthebrakestocool.

6.Repeatsteps3through5anadditional9

times.

•Avoidracingtheengine.

•Varythesprayerspeedduringoperation.Avoid

faststartsandquickstops.

•RefertoMaintenance(page41)foranyspecial,

low-hourchecks.

PreparingtheSprayer

SelectingaNozzle

Note:Refertothenozzle-selectionguidethatis

availablethroughyourauthorizedTorodistributor.

Theturretbodiescanacceptupto3differentnozzles.

Toselectthedesirednozzle,performthefollowing:

1.Stopthesprayeronalevelsurface,shutoffthe

engine,andengagetheparkingbrake.

2.SetthemastersectionswitchtotheOFFposition

andsetthespray-pumpswitchtotheOFF

position.

3.Rotatetheturretofthenozzlesineitherdirection

tothecorrectnozzle.

4.Performaowcalibration;refertoCalibrating

theSprayerFlow(page27).

SelectingaSuctionFilter

StandardEquipment:50meshsuctionlter(blue)

Usethesuctionltertabletoidentifythescreen

meshforthespraynozzlesyouareusingbased

onchemicalsproductsorsolutionswithaviscosity

equivalenttowater.

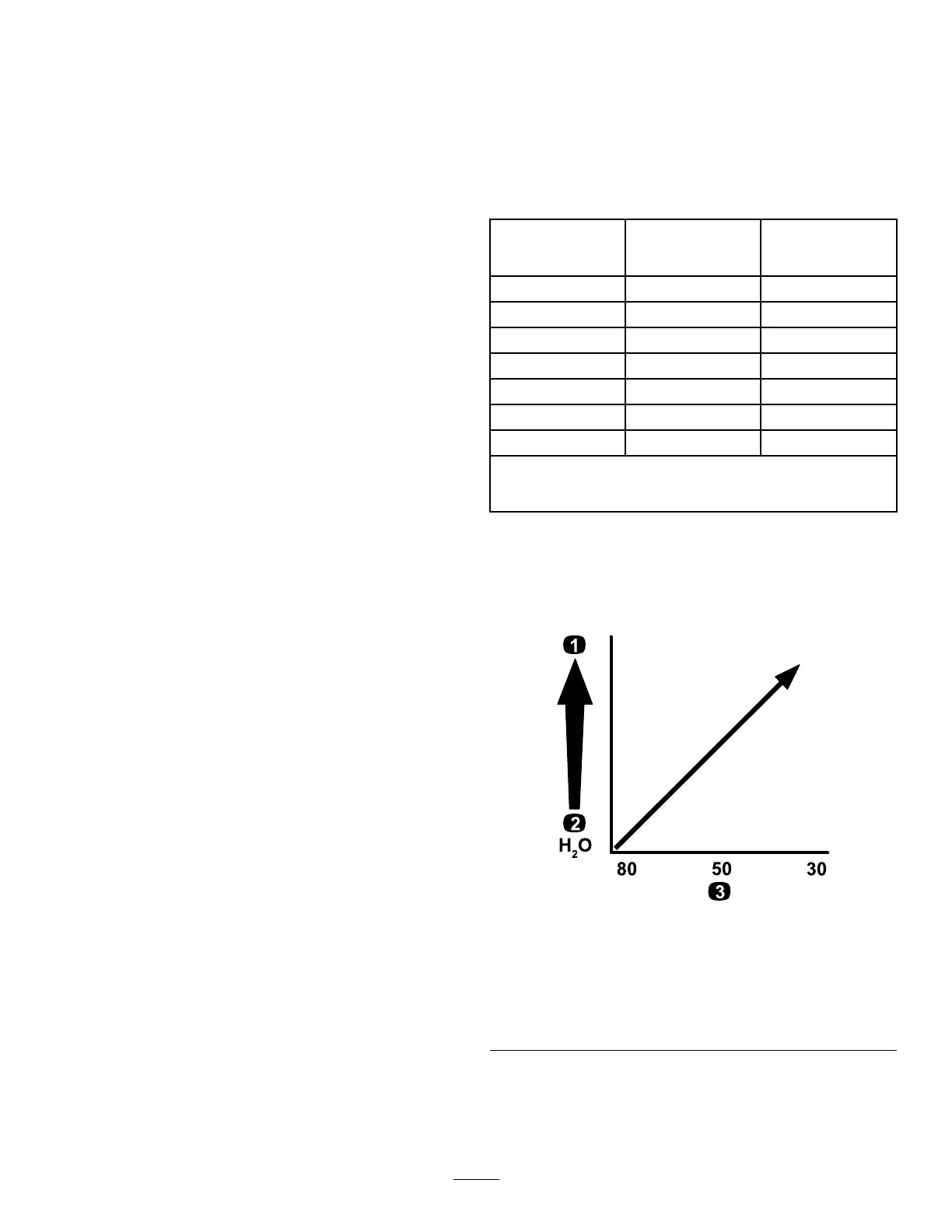

SuctionFilterTable

SprayNozzle

ColorCode(ow

rate)

ScreenMesh

Size*

FilterColorCode

Yellow(0.2gpm)

50Blue

Red(0.4gpm)

50Blue

Brown(0.5gpm)50(or30)Blue(orgreen)

Gray(0.6gpm)

30

Green

White(0.8gpm)

30

Green

Blue(1.0gpm)

30

Green

Green(1.5gpm)

30

Green

*Themeshsizeofthesuctionltersinthistable

arebasedonspraychemicalsorsolutionswiththe

viscosityequivalenttowater.

Important:Whenyouspraywithhigherviscosity

(thicker)chemicalproductsorsolutionswith

wettablepowders,youmayneedtouseancoarser

screenmeshfortheoptionalsuctionlter;refer

toFigure13.

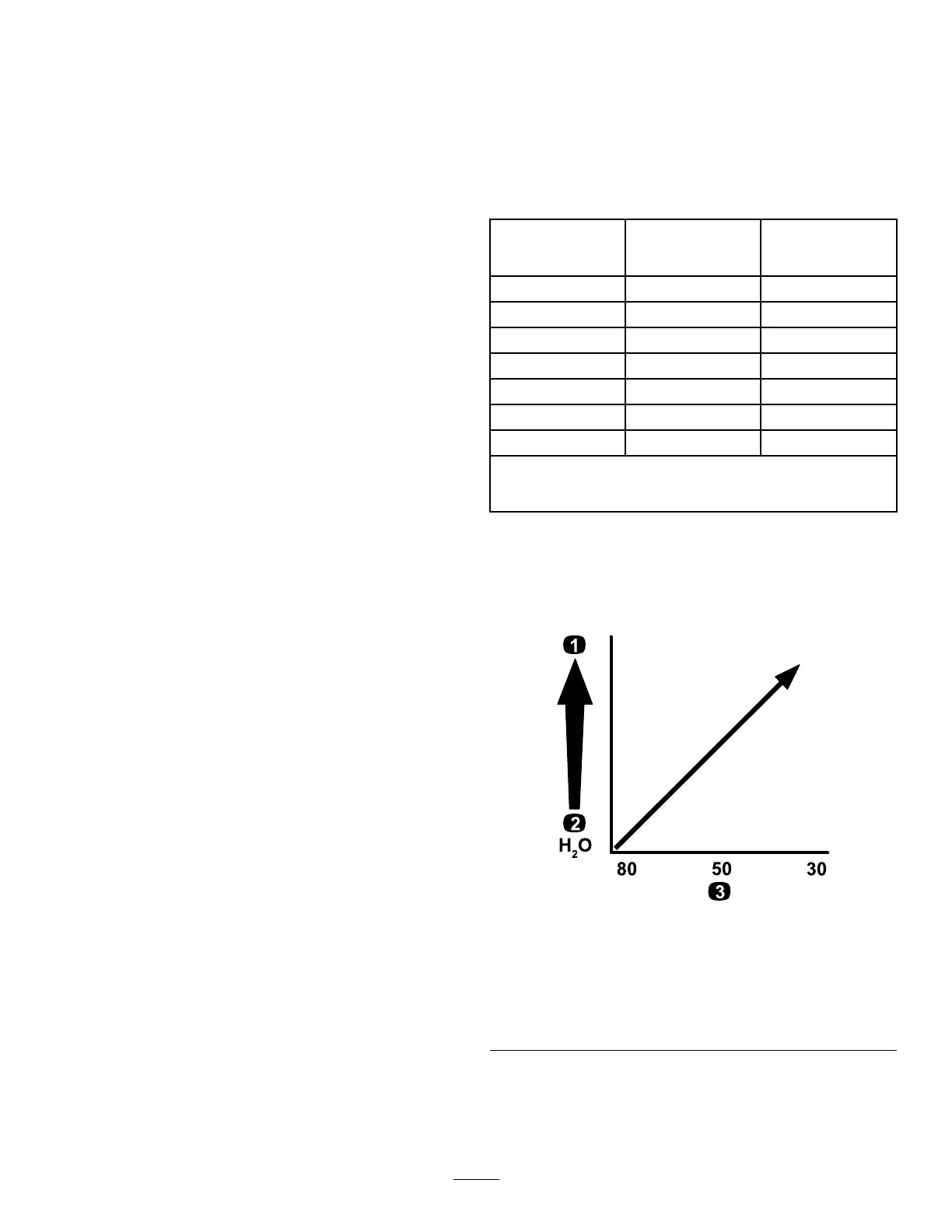

g214212

Figure13

Meshsize—chemicalorsolutionviscosity

1.Higher-viscositychemicals

orsolutions

3.Screenmeshsize

2.Lower-viscositychemicals

orsolutions

Whenyousprayatahigherapplicationrate,consider

usingacourseroptionalsuction-ltermesh;referto

Figure14.

23

Loading...

Loading...