unlessfounddefectiveandarenotcoveredbythe

warrantyassociatedwiththismachine.

HaveanauthorizedT orodistributorcheckfollowing

internalpumpcomponentsfordamage:

•Pumpdiaphragms

•Pumpcheckvalvesassemblies

Replaceanycomponents,ifnecessary.

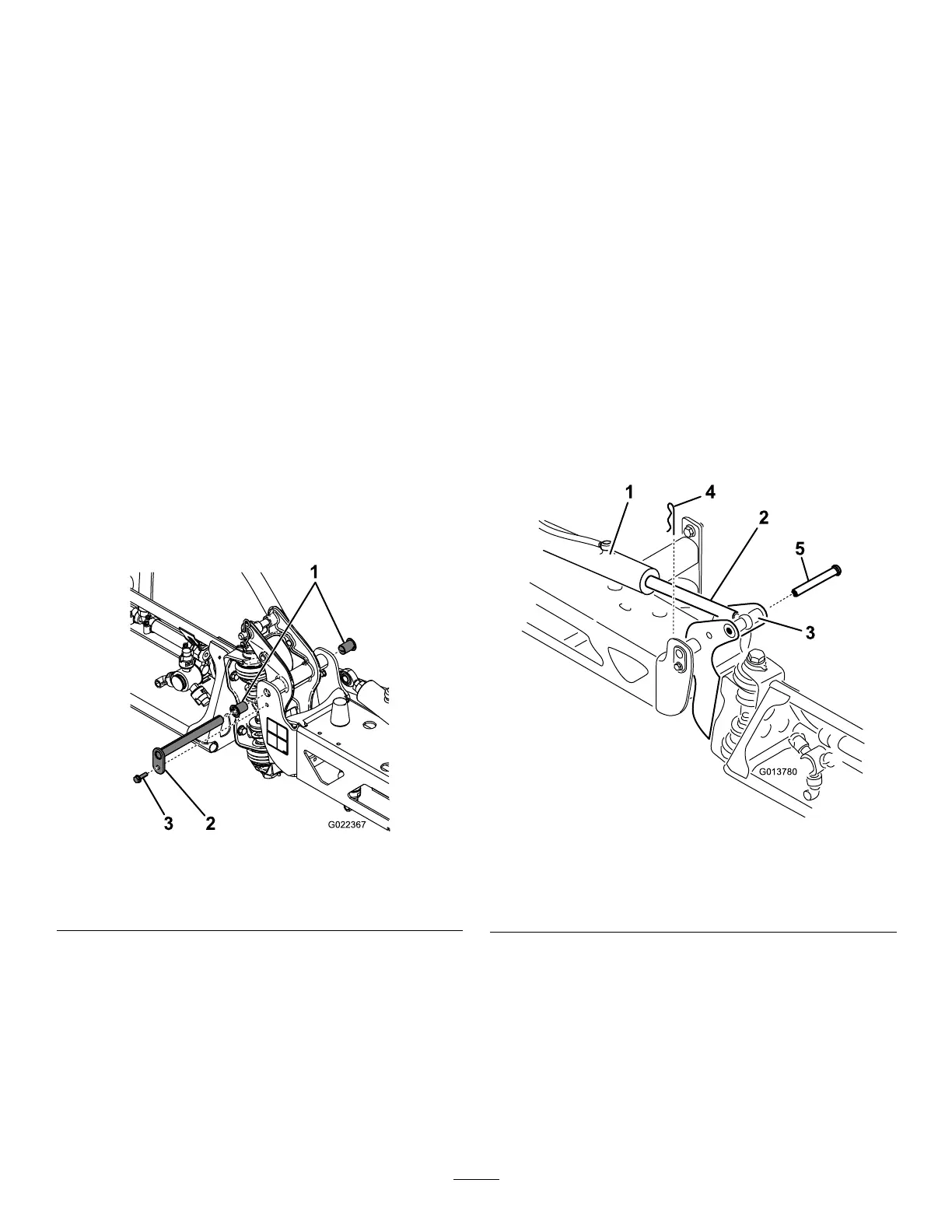

InspectingtheNylonPivot

Bushings

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutoffthepump,shutoffthe

engine,andremovethekey.

2.Extendtheouter-boomsectionstothespray

positionandsupporttheboomsusingstandsor

strapsandliftingequipment.

3.Withtheweightoftheboomsupported,remove

theboltandnutsecuringthepivotpintothe

boomassembly(Figure62).

g022367

Figure62

1.Nylonbushings3.Bolt

2.Pivotpin

4.Removetheboltandnutthatsecurethepivot

pin,andremovethepin(Figure62).

5.Removetheboomandpivotbracketassembly

fromthecenterframetoaccessthenylon

bushings.

6.Removeandinspectthenylonbushingsfrom

thefrontandbacksidesofthepivotbracket

(Figure62).

Note:Replaceanywornordamagedbushings.

7.Placeasmallamountofoilonthenylon

bushings,andinstallthemintopivotbracket

(Figure62).

8.Installtheboomandpivotbracketassemblyinto

thecenterframe,aligningtheholes(Figure62).

9.Installthepivotpinandsecureitwiththebolt

andnutremovedinstep4.

10.Repeatsteps2through9fortheother

outer-boomsection.

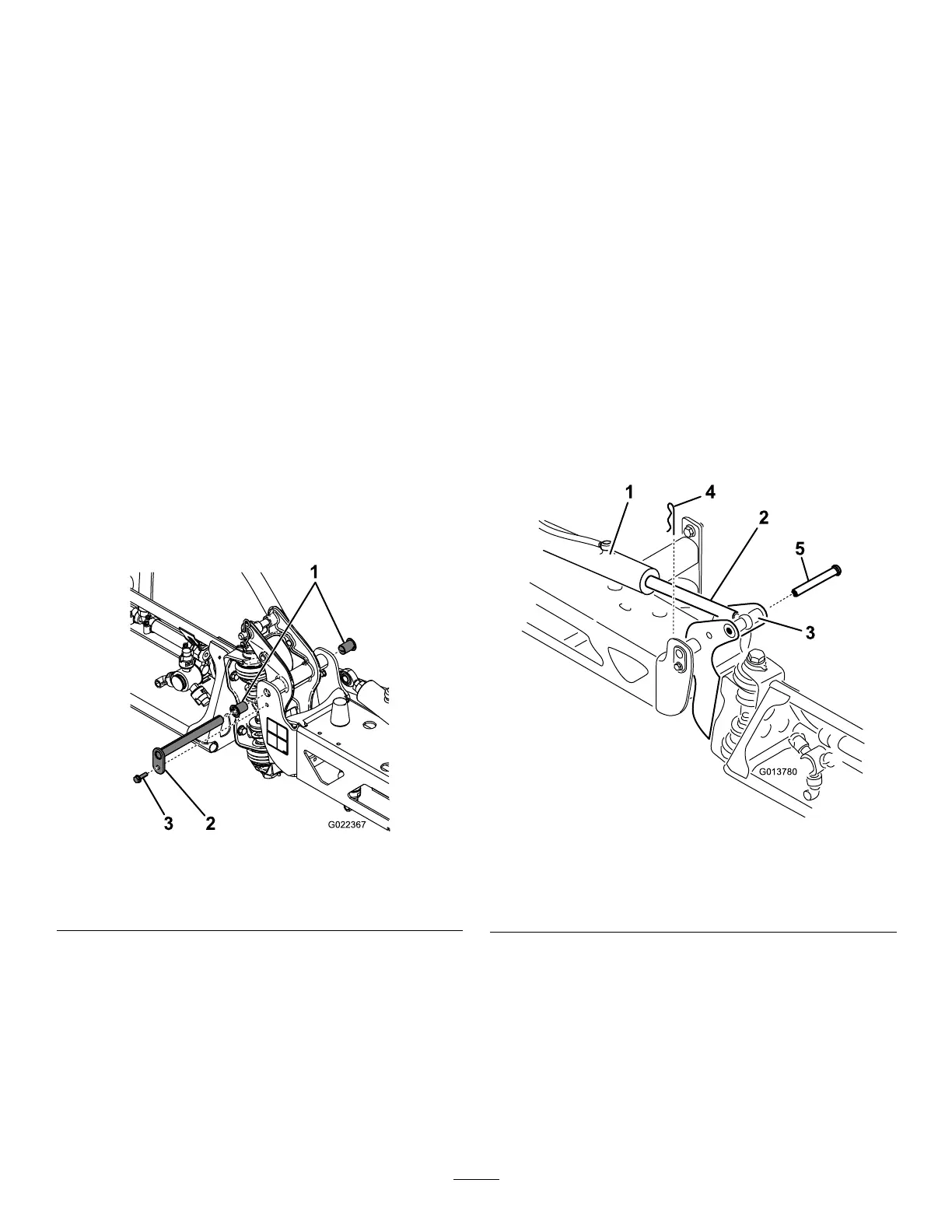

AdjustingtheBoomsto

Level

Usethefollowingproceduretoadjustthelevelofthe

leftandrightboomssectionswhentheyareinthe

sprayposition.

1.Extendtheboomstothesprayposition.

2.Removethecotterpinfromthepivotpin(Figure

63).

g013780

Figure63

1.Actuator

4.Cotter

2.Actuatorrod5.Pin

3.Boom-pivotpinhousing

3.Liftupontheboomandremovethepin(Figure

63),andslowlylowertheboomtotheground.

4.Inspectthepinforanydamageandreplaceit

ifnecessary.

5.Useawrenchontheatsidesoftheactuator

rodtoimmobilizeit,thenloosenthejamnutto

allowtheeyeletrodtobeadjusted(Figure64).

60

Loading...

Loading...