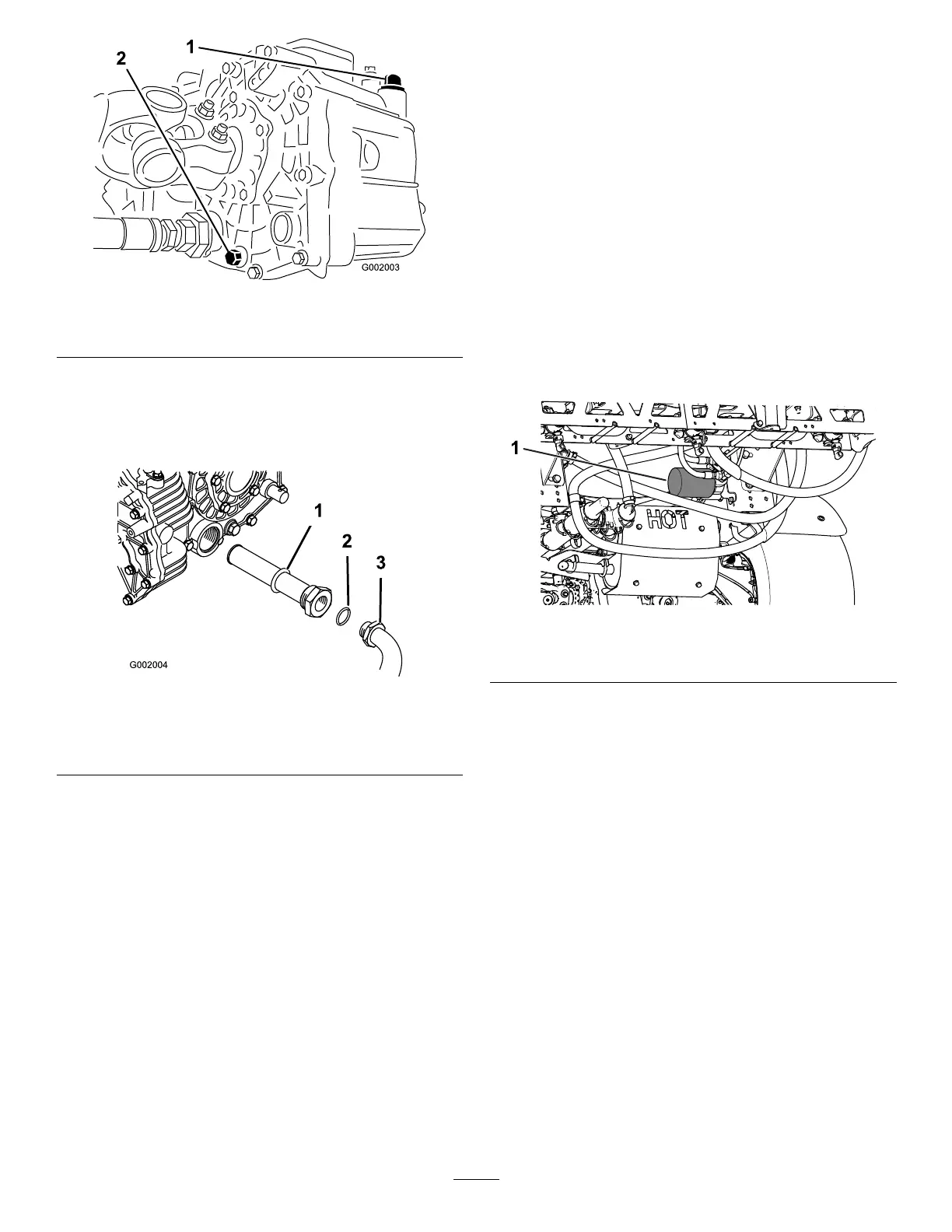

g002003

Figure55

1.Hydraulicdipstick2.Drainplug

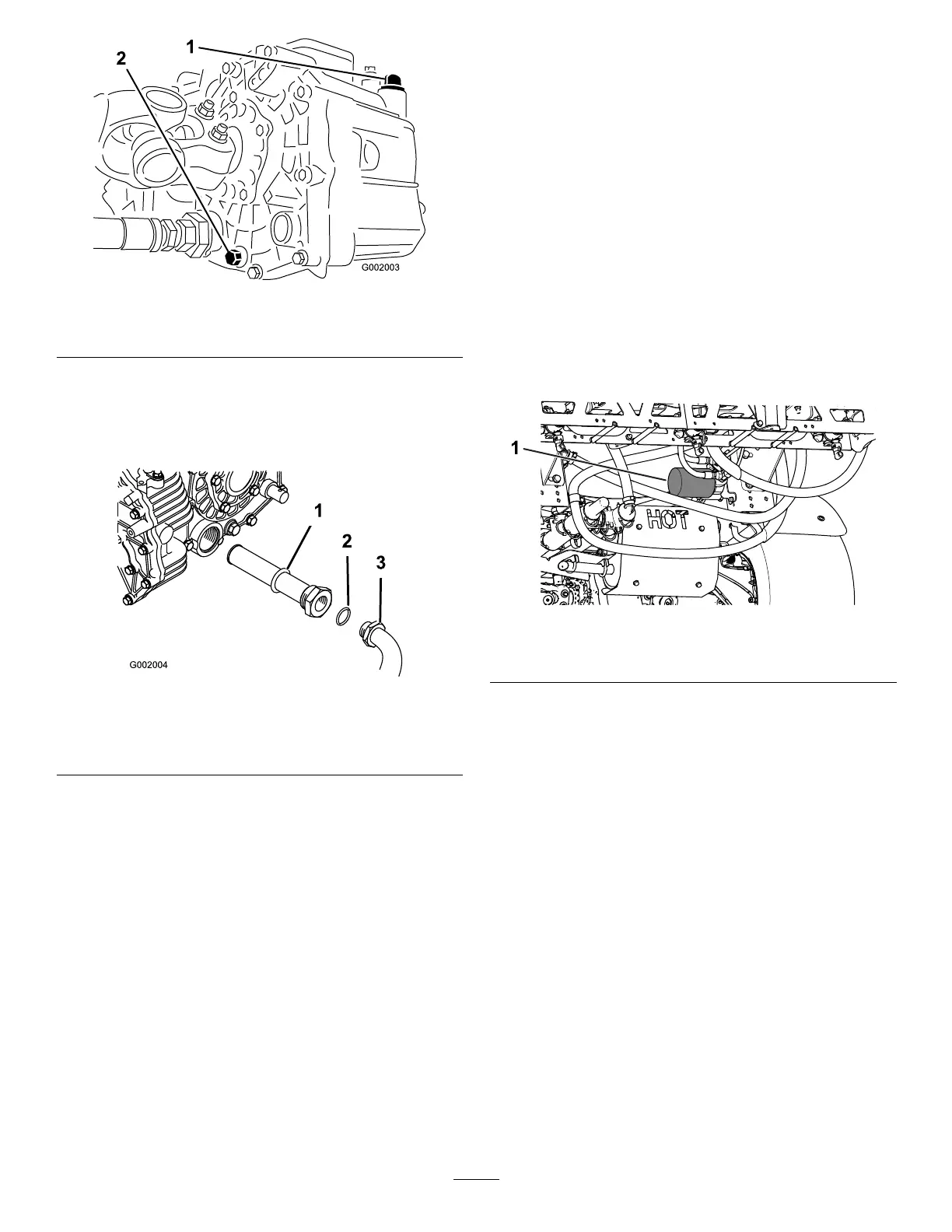

4.Notetheorientationofthehydraulichoseand

90°ttingconnectedtothestrainer.

5.Removethehydraulichoseand90°tting

(Figure56).

g002004

Figure56

1.Hydraulicstrainer

3.90°tting

2.O-ring

6.Removethestrainerandcleanitbyback

ushingitwithacleandegreaser.

7.Allowthestrainertoairdry.

8.Installthestrainerwhentheoilisdraining.

9.Installthehydraulichoseand90°ttingtothe

strainer.

10.Installandtightenthedrainplug.

11.Fillthereservoirwithapproximately7L(7.5US

qt)ofDexronIIIATF.

Important:Useonlythehydraulicuids

specied.Otheruidscouldcausesystem

damage.

12.Starttheengineanddrivethesprayertollthe

hydraulicsystem.

13.Checktheoillevelandreplenishit,ifrequired.

ReplacingtheHydraulic

Filter

ServiceInterval:Aftertherst8hours

Every800hours/Yearly(whichevercomesrst)

UsetheTororeplacementlter(PartNo.54-0110).

Important:Useofanyotherltermayvoidthe

warrantyonsomecomponents.

1.Positionthesprayeronalevelsurface,set

theparkingbrake,stopthepump,shutoffthe

engine,andremovetheignitionkey.

2.Cleantheareaaroundtheltermountingarea.

3.Placeadrainpanunderthelter.

4.Removethelter(Figure57).

g204330

Figure57

1.Hydrauliclter

5.Lubricatethenewltergasket.

6.Ensurethattheltermountingareaisclean.

7.Screwthelteronuntilthegasketcontactsthe

mountingplate,thentightenthelter1/2turn.

8.Starttheengineandletitrunforabout2minutes

topurgeairfromthesystem.

9.Shutofftheengineandcheckthehydraulic-uid

levelandforleaks;refertoCheckingthe

Transaxle/HydraulicFluid(page56).

CheckingtheHydraulic

LinesandHoses

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

57

Loading...

Loading...