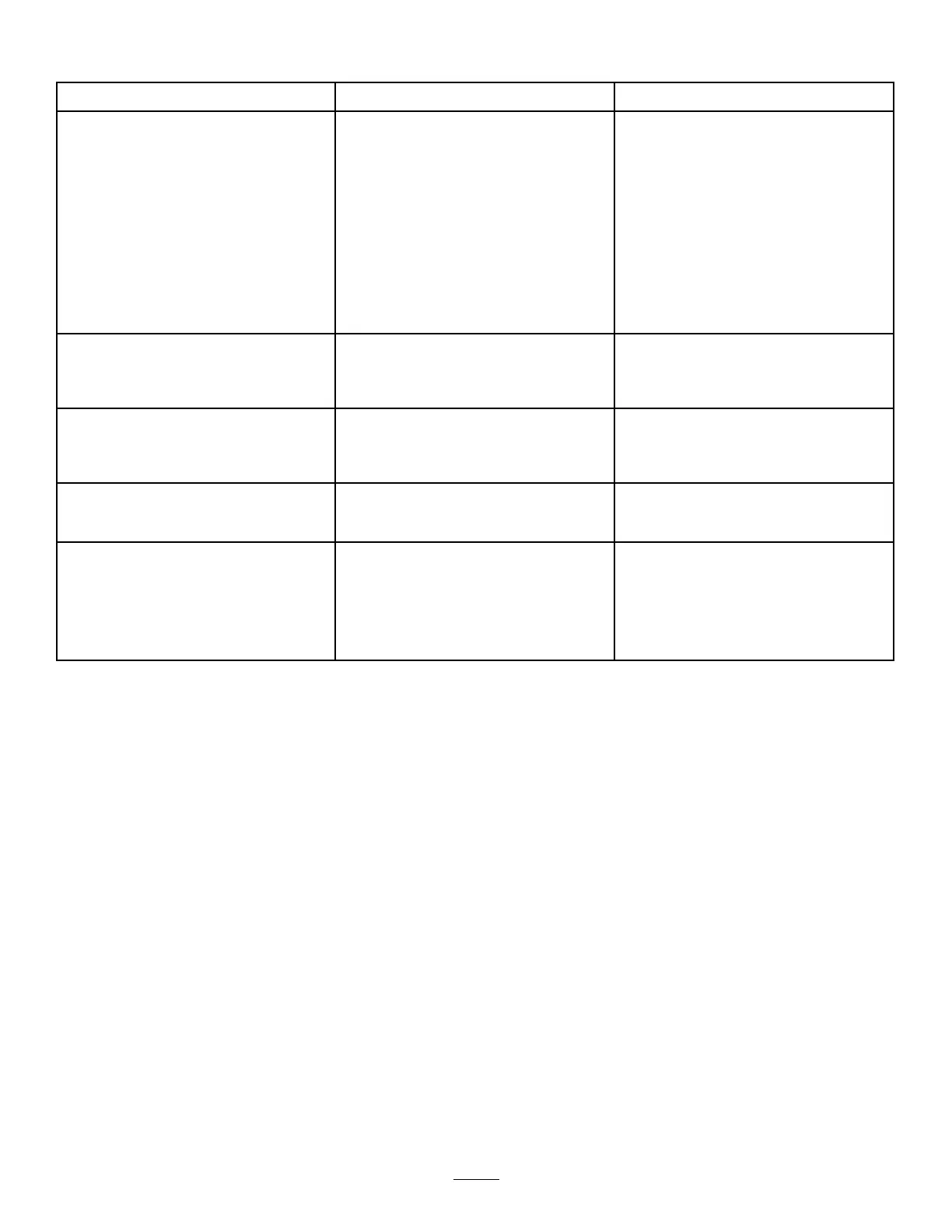

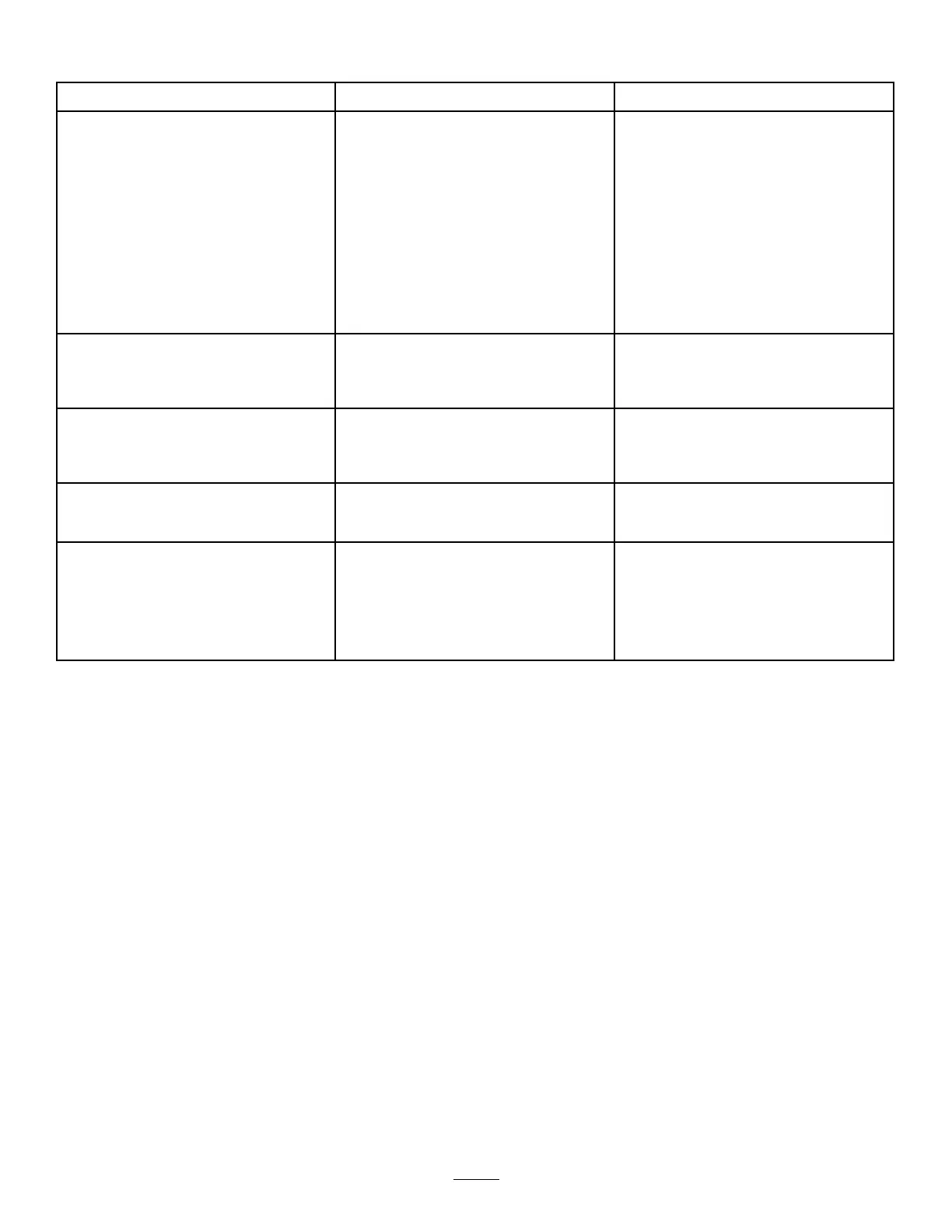

TroubleshootingtheSpraySystem

Problem

PossibleCauseCorrectiveAction

1.Theelectricalconnectiononthe

sectionvalveisdirtyordisconnected.

1.Turnthevalveoffmanually.Disconnect

theelectricalconnectoronthevalve

andcleanallleads,thenconnectit.

2.Thereisablownfuse.2.Checkthefusesandreplacethemas

necessary.

3.Thereisapinchedhose.3.Repairorreplacethehose.

4.Asectionbypassisimproperly

adjusted.

4.Adjustthesectionbypass.

5.Therearedamagedsectionvalve.

5.ContactyourauthorizedT oro

distributor.

Asectiondoesnotspray.

6.Theelectricalsystemisdamaged.

6.ContactyourauthorizedT oro

distributor.

Asectiondoesnotturnoff.

1.Thesectionvalveisdamaged.

1.Disassemblethesectionvalve;refer

tothesectionCleaningtheSprayer

Valves.Inspectallofthepartsand

replaceanythataredamaged.

Asectionvalveisleaking.1.Asealorvalveseatiswornor

damaged.

1.Disassemblethevalveandreplace

thesealsusingtheValveRepair

Kit;contactyourauthorizedT oro

distributor.

Thespraynozzle(s)dripwhenthesection

switch(es)isshutoff

1.Debrishasaccumulatedbetween

thenozzlebodyandthecheck-valve

diaphragm.

1.Cleanthenozzlebodyanddiaphragm;

refertoCleaningtheNozzleBodyand

Check-ValveDiaphragm.

1.Thesectionbypassisimproperly

adjusted.

1.Adjustthesectionbypass.

2.Thereisanobstructioninthesection

valvebody.

2.Removetheinletandoutlet

connectionstothesectionvalve

andremoveanyobstructions.

Apressuredropoccurswhenyouturnon

asection.

3.Anozzlelterisdamagedorclogged.

3.Removeandinspectallnozzles.

75

Loading...

Loading...