2

Installing the Roll Bar

Parts needed for this procedure:

1 Roll bar

6

Flange-head bolt (1/2 x 1-1/4 inches)

Procedure

1. Apply medium-grade (service-removable)

thread-locking compound to the threads of the 6

ange-head bolts (1/2 x 1-1/4 inches).

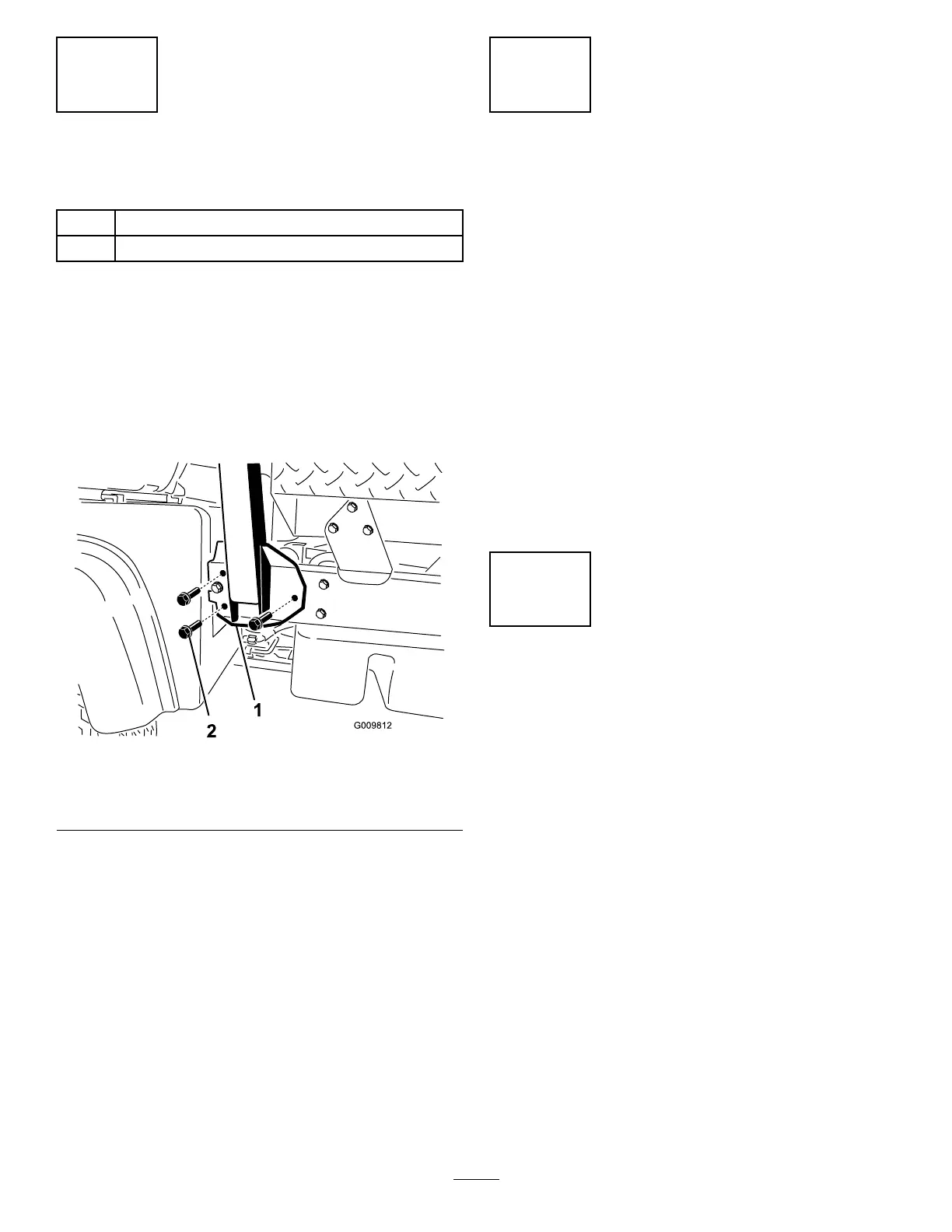

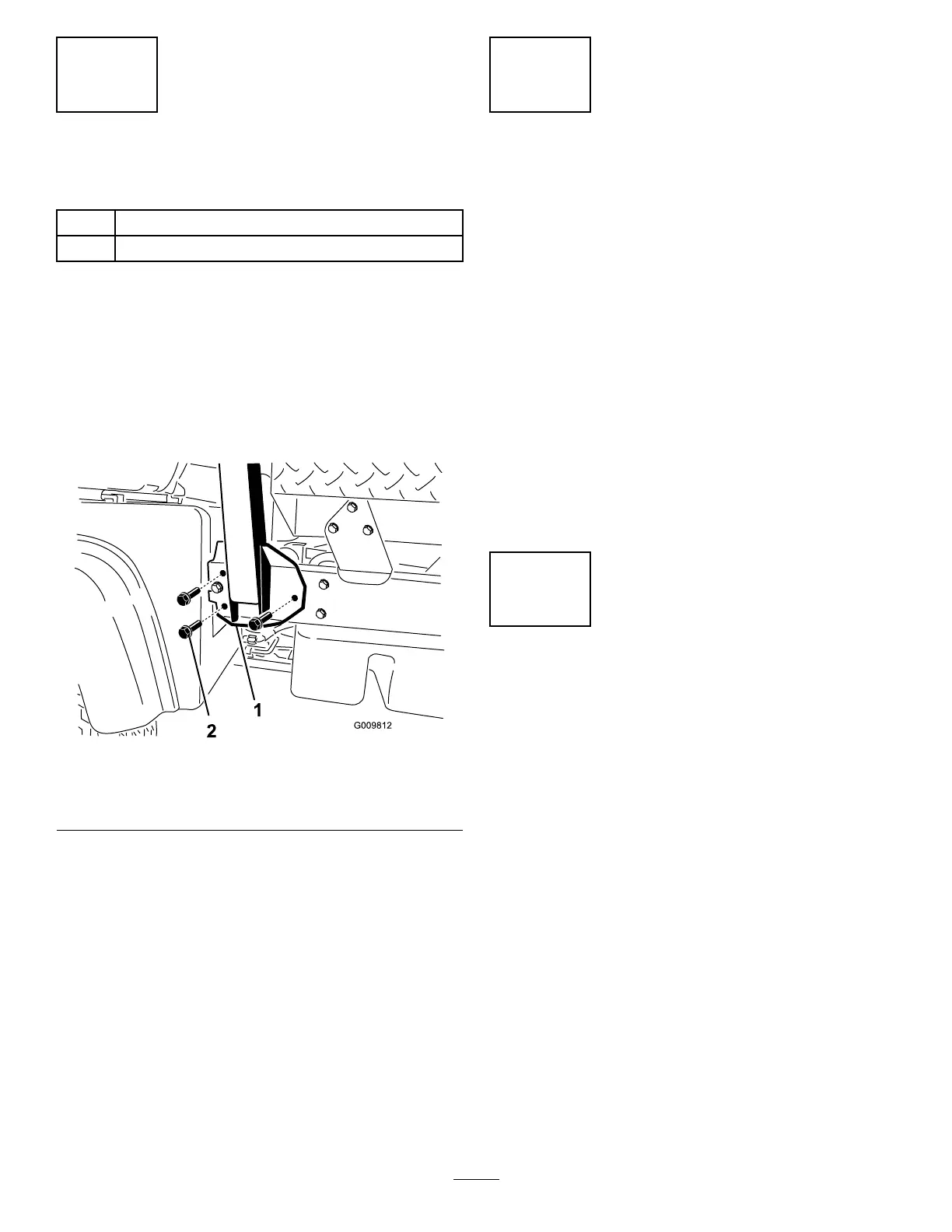

2. Align each side of the roll bar with the mounting

holes on each side of the machine frame ( Figure

4 ).

g009812

Figure 4

1. Roll bar mounting bracket

2. Flange-head bolt (1/2 x

1-1/4 inches)

3. Secure the roll bar mounting bracket to the

machine frame using 3 ange-head bolts (1/2 x

1-1/4 inches) on each side ( Figure 4 ).

4. T orque the ange-head bolts (1/2 x 1-1/4 inches)

to 1 15 N∙m (85 ft-lb).

3

Checking the Fluid Levels

and T ire Pressure

No Parts Required

Procedure

1. Check the engine-oil level before and after

you rst start the engine; refer to Checking the

Engine-Oil Level ( page 42 ) .

2. Check the transaxle/hydraulic-uid level before

you rst start the engine; refer to Checking the

T ransaxle/Hydraulic-Fluid Level ( page 57 ) .

3. Check the brake-uid level before you rst start

the engine; refer to Checking the Brake-Fluid

Level ( page 53 ) .

4. Check the air pressure in the tires; refer to

Checking the T ire Pressure ( page 21 ) .

4

Burnishing the Brakes

No Parts Required

Procedure

T o ensure optimum performance of the brake system,

burnish the brakes before use.

1. Bring the machine up to full speed, apply the

brakes to rapidly stop the machine without

locking up the tires.

2. Repeat this procedure 10 times, waiting 1 minute

between stops, to avoid overheating the brakes.

Important: This procedure is most effective

if the machine is loaded with 454 kg (1,000

lb).

13

Loading...

Loading...