Servicing the High-Flow

Hydraulic System

TC Models Only

Hydraulic Fluid Specications

The reservoir is lled at the factory with high-quality

hydraulic uid. Check the level of the hydraulic uid

before you rst start the engine and daily thereafter;

refer to Checking the High-Flow Hydraulic-Fluid Level

( page 60 ) .

Recommended replacement uid: T oro PX

Extended Life Hydraulic Fluid; available in 19 L (5 US

gallon) pails or 208 L (55 US gallon) drums.

Note: A machine using the recommended

replacement uid requires less frequent uid and lter

changes.

Alternative uids: If T oro PX Extended Life

Hydraulic Fluid is not available, you may use another

conventional, petroleum-based hydraulic uid having

specications that fall within the listed range for all the

following material properties and that it meets industry

standards. Do not use synthetic uid. Consult with

your lubricant distributor to identify a satisfactory

product.

Note: T oro does not assume responsibility for

damage caused by improper substitutions, so use

products only from reputable manufacturers who will

stand behind their recommendation.

High V iscosity Index/Low Pour Point

Anti-wear Hydraulic Fluid, ISO VG 46

Material Properties:

V iscosity , ASTM D445 cSt @ 40°C (104°F)

44 to 48

V iscosity Index ASTM D2270

140 or higher

Pour Point, ASTM D97 -37°C to -45°C (-34°F

to -49°F)

Industry Specications: Eaton V ickers 694 (I-286-S,

M-2950-S/35VQ25 or

M-2952-S)

Note: Many hydraulic uids are almost colorless,

making it dif cult to spot leaks. A red dye additive for

the hydraulic uid is available in 20 ml (0.67 oz)

bottles. A bottle is suf cient for 15 to 22 L (4 to 6 US

gallons) of hydraulic uid. Order Part No. 44-2500

from your authorized T oro distributor .

Checking the High-Flow

Hydraulic-Fluid Level

TC Models Only

Service Interval : Before each use or daily —Check

the high-ow hydraulic-uid level

(TC models only). (Check the level

of hydraulic uid before the engine

is rst started, and daily thereafter)

1. Park the machine on a level surface.

2. Engage the parking brake.

3. Shut of f the engine and remove the key .

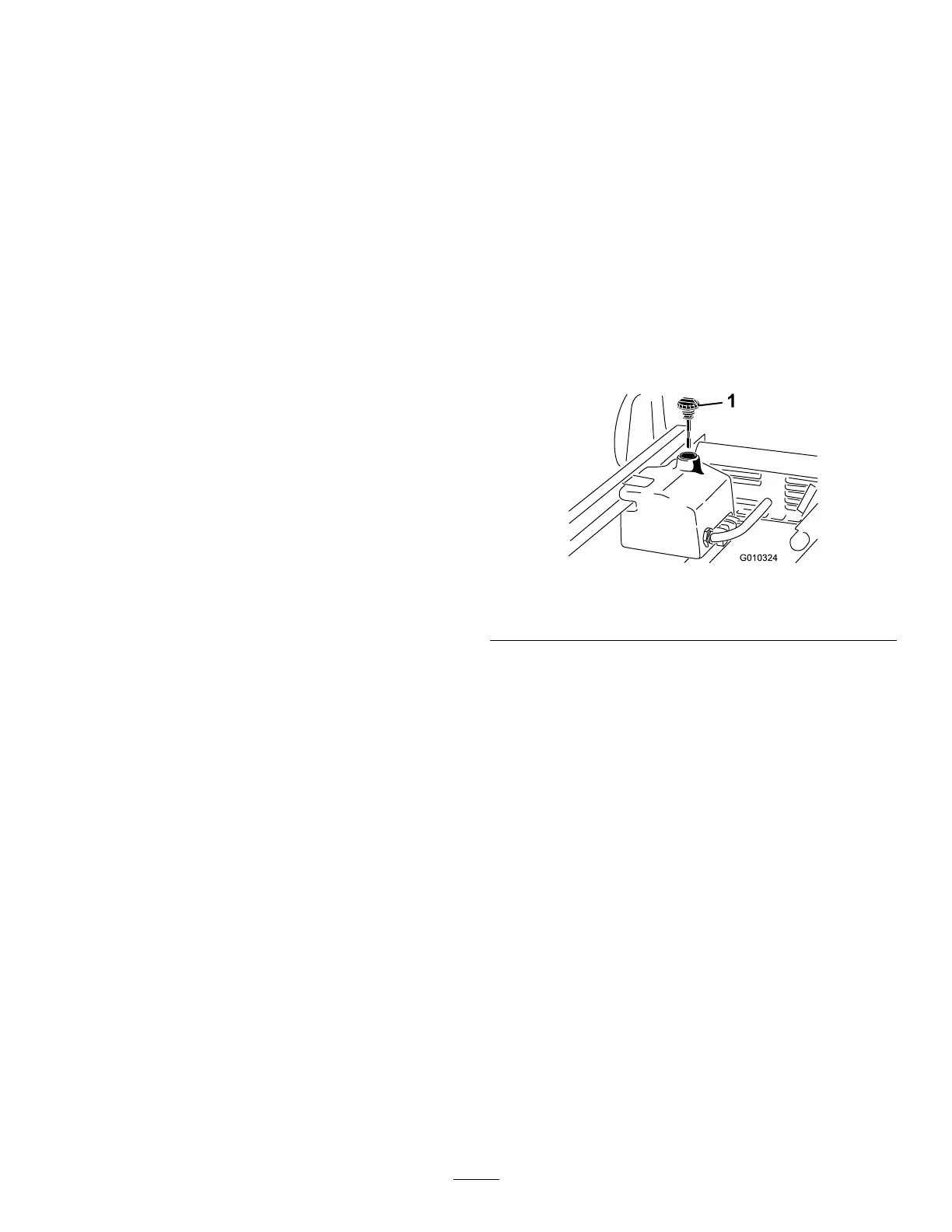

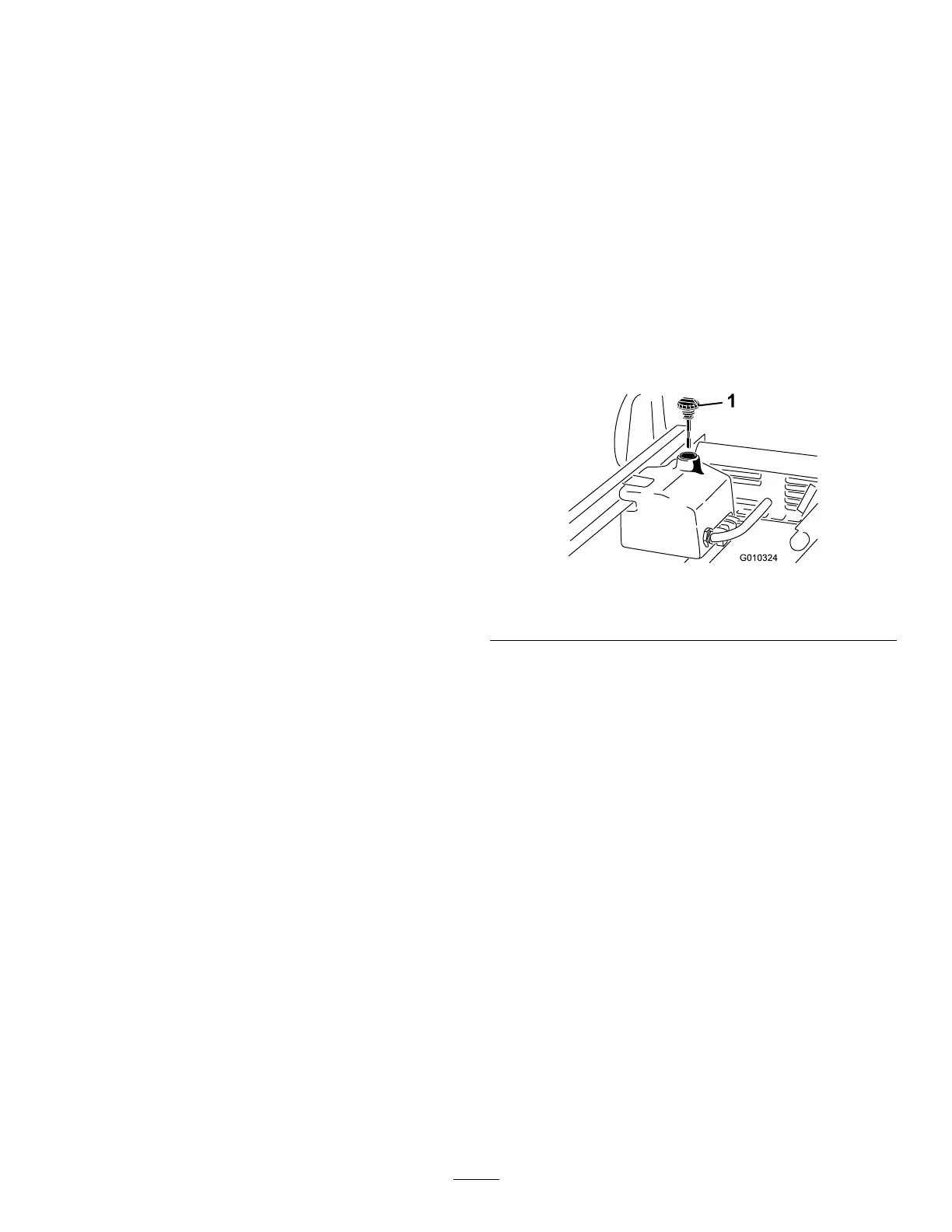

4. Clean the area around the ller neck and the

cap of the hydraulic tank ( Figure 70 ).

5. Remove the cap from the ller neck.

g010324

Figure 70

1. Cap

6. Remove the dipstick ( Figure 70 ) from the ller

neck and wipe it with a clean rag.

7. Insert the dipstick into the ller neck, then

remove it and check the uid level.

Note: The uid level should be between the 2

marks on the dipstick.

8. If the level is low , add the appropriate uid

to raise the level to the upper mark; refer to

Changing the High-Flow Hydraulic Fluid and

Filter ( page 61 ) .

9. Install the dipstick and cap onto the ller neck.

10. Start the engine and turn on the attachment.

Note: Let them run for about 2 minutes to purge

air from the system.

Important: The machine must be running

before starting the high-ow hydraulics.

1 1. Shut of f the engine and attachment and check

for leaks.

60

Loading...

Loading...