Adjusting the Accelerator

Pedal

1. Park the machine on a level surface, engage the

parking brake, shut of f the engine, and remove

the key .

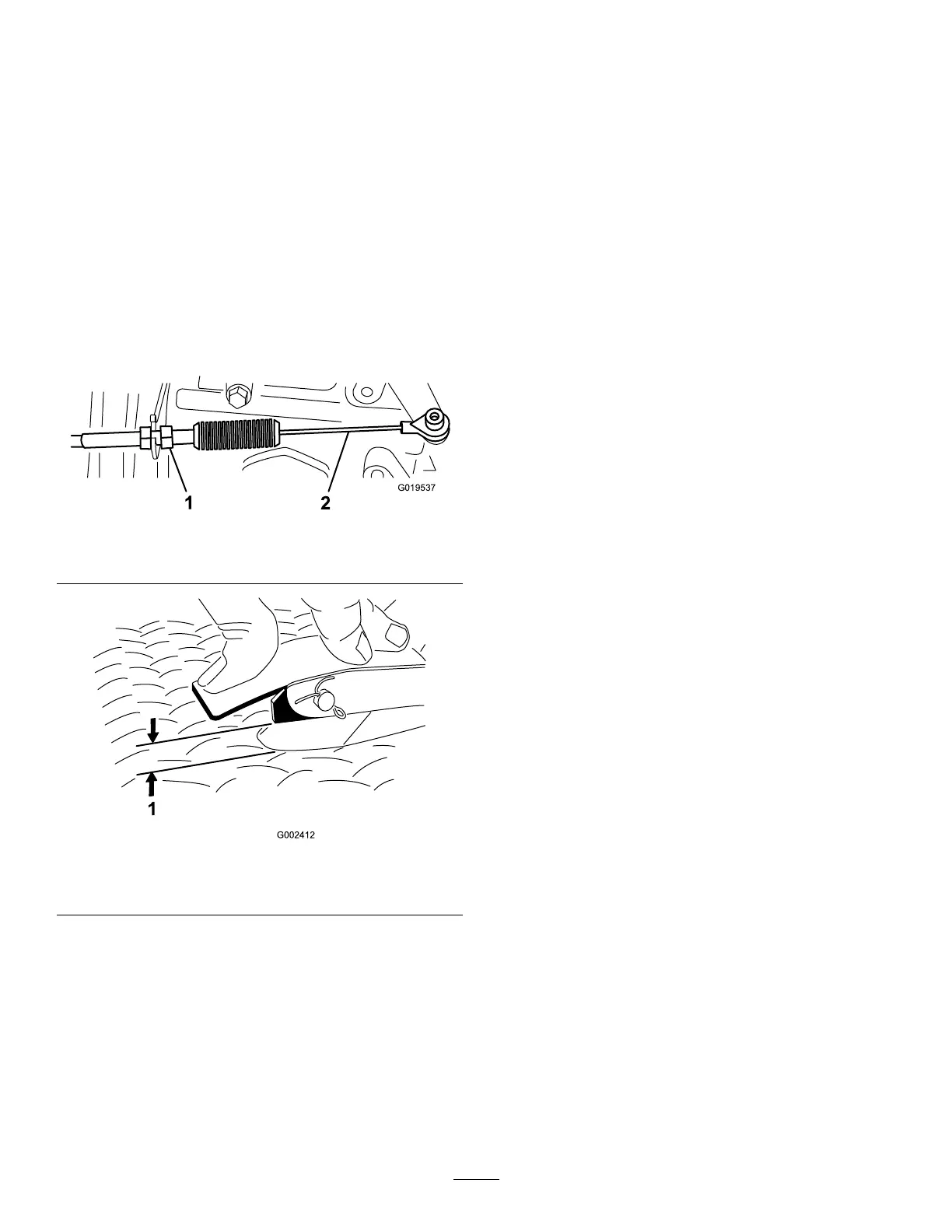

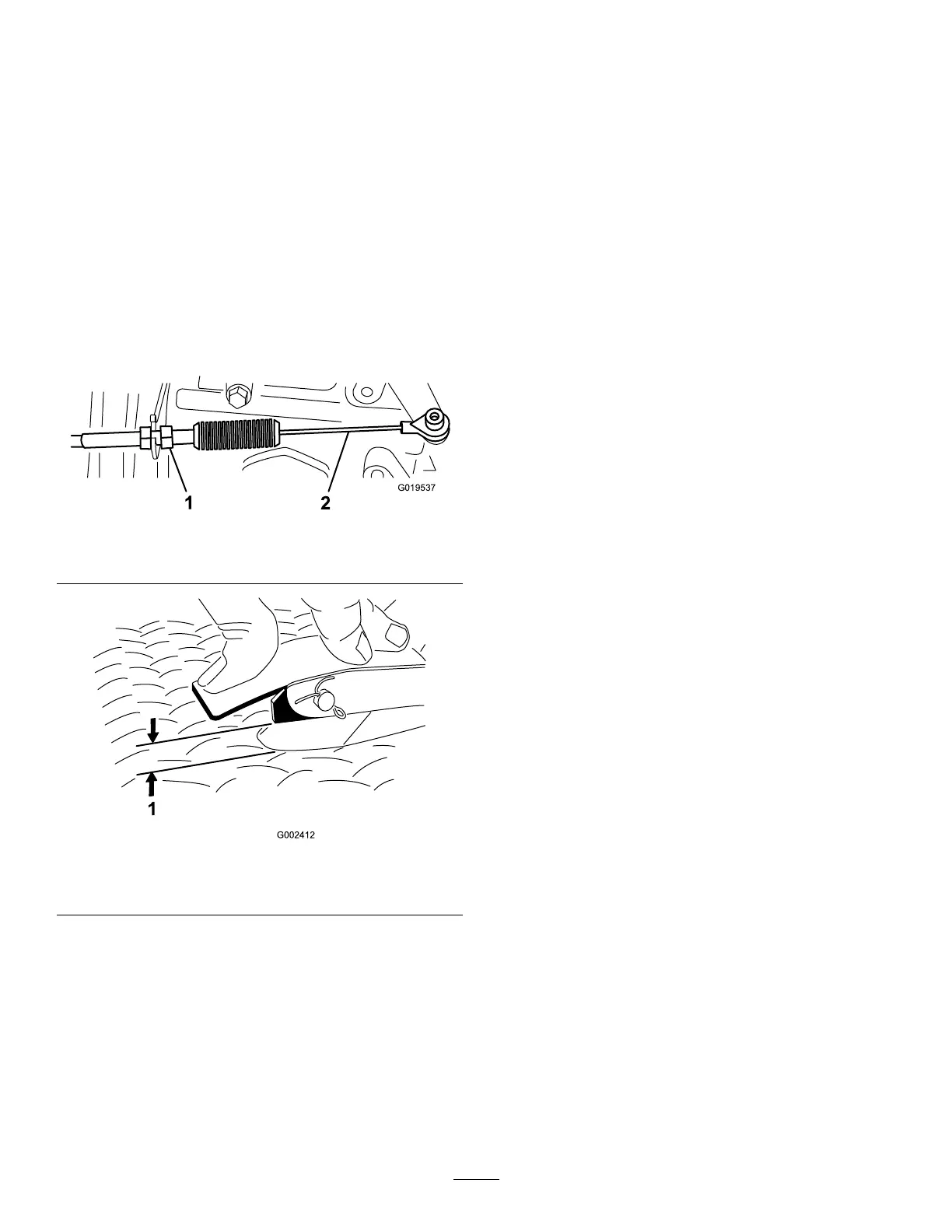

2. Adjust the ball joint on the accelerator cable

( Figure 64 ) to allow 2.54 to 6.35 mm (0.100 to

0.250 inch) of clearance between the accelerator

pedal arm and the top of the diamond tread oor

plate ( Figure 65 ), when you apply 1 1.3 kg (25 lb)

of force to the center of the pedal.

Note: The engine must not be running and the

return spring must be attached.

3. T ighten the locknut ( Figure 64 ).

g019537

Figure 64

1. Locknut 2. Accelerator cable

g002412

Figure 65

1. 2.54 to 6.35 mm (0.100 to 0.250 inch) clearance

Important: The maximum high-idle speed is 3,650

rpm. Do not adjust the high-idle stop.

Hydraulic System

Maintenance

Hydraulic System Safety

• Seek immediate medical attention if uid is injected

into skin. Injected uid must be surgically removed

within a few hours by a doctor .

• Before disconnecting or performing any work on

the hydraulic system, relieve all pressure in the

system by shutting of f the engine, cycling the

dump valve from raise to lower , and/or lowering

the cargo bed and attachments. Place the remote

hydraulics lever in the oat position. Do not work

under a raised bed without the proper bed safety

support in place.

• Ensure that all hydraulic-uid hoses and lines are

in good condition and that all hydraulic connections

and ttings are tight before applying pressure to

the hydraulic system.

• Keep your hands and body away from pinhole

leaks or nozzles that eject high-pressure hydraulic

uid.

• Use cardboard or paper to nd hydraulic leaks.

Servicing the

T ransaxle/Hydraulic

System

T ransaxle/Hydraulic Fluid

Specications

T ransaxle-uid type: Dexron III A TF

Checking the

T ransaxle/Hydraulic-Fluid Level

Service Interval : Before each use or daily —Check

the transaxle/hydraulic-uid level.

(Check the uid level before the

engine is rst started and every 8

hours or daily , thereafter .)

1. Park the machine on a level surface.

2. Engage the parking brake.

3. Shut of f the engine and remove the key .

4. Clean the area around the dipstick ( Figure 66 ).

57

Loading...

Loading...