3. Pivot the top of the hood forward and unplug the

wire connectors from the headlights ( Figure 28 ).

4. Remove the hood.

Installing the Hood

1. Connect the lights.

2. Insert the top mounting tabs into the frame slots

( Figure 28 ).

3. Insert the lower mounting tabs into the frame

slots ( Figure 28 ).

4. Ensure that the hood is fully engaged in the top,

sides, and bottom grooves.

Lubrication

Greasing the Bearings and

Bushings

Service Interval : Every 100 hours (lubricate

more frequently in heavy-duty

applications).

Grease T ype: No. 2 lithium grease

1. Use a rag to wipe the grease tting clean so that

foreign matter cannot be forced into the bearing

or bushing.

2. With a grease gun, apply grease into the grease

ttings on the machine.

3. Wipe any excess grease of f the machine.

Important: When greasing the drive shaft

universal shaft bearing crosses, pump grease

until it comes out of all 4 cups at each cross.

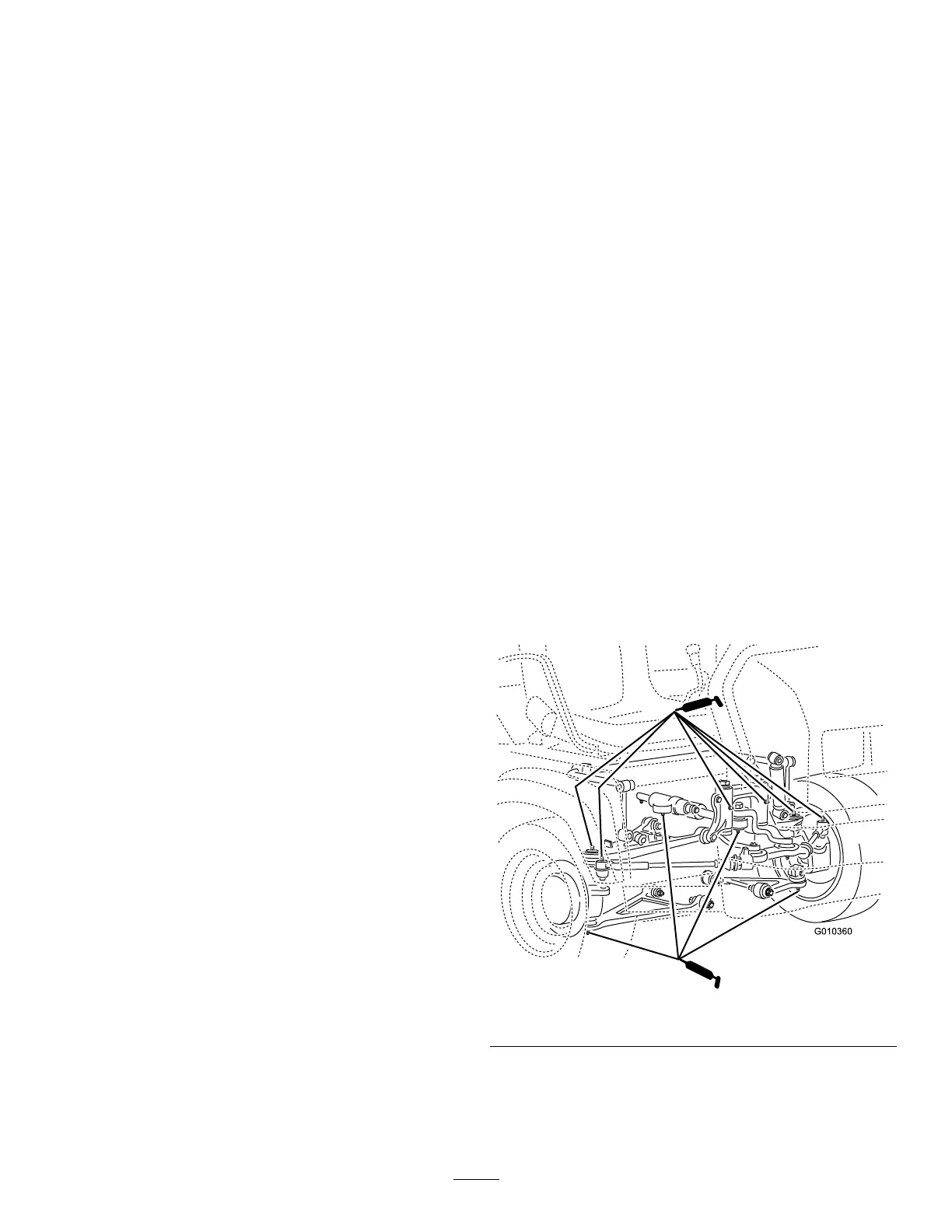

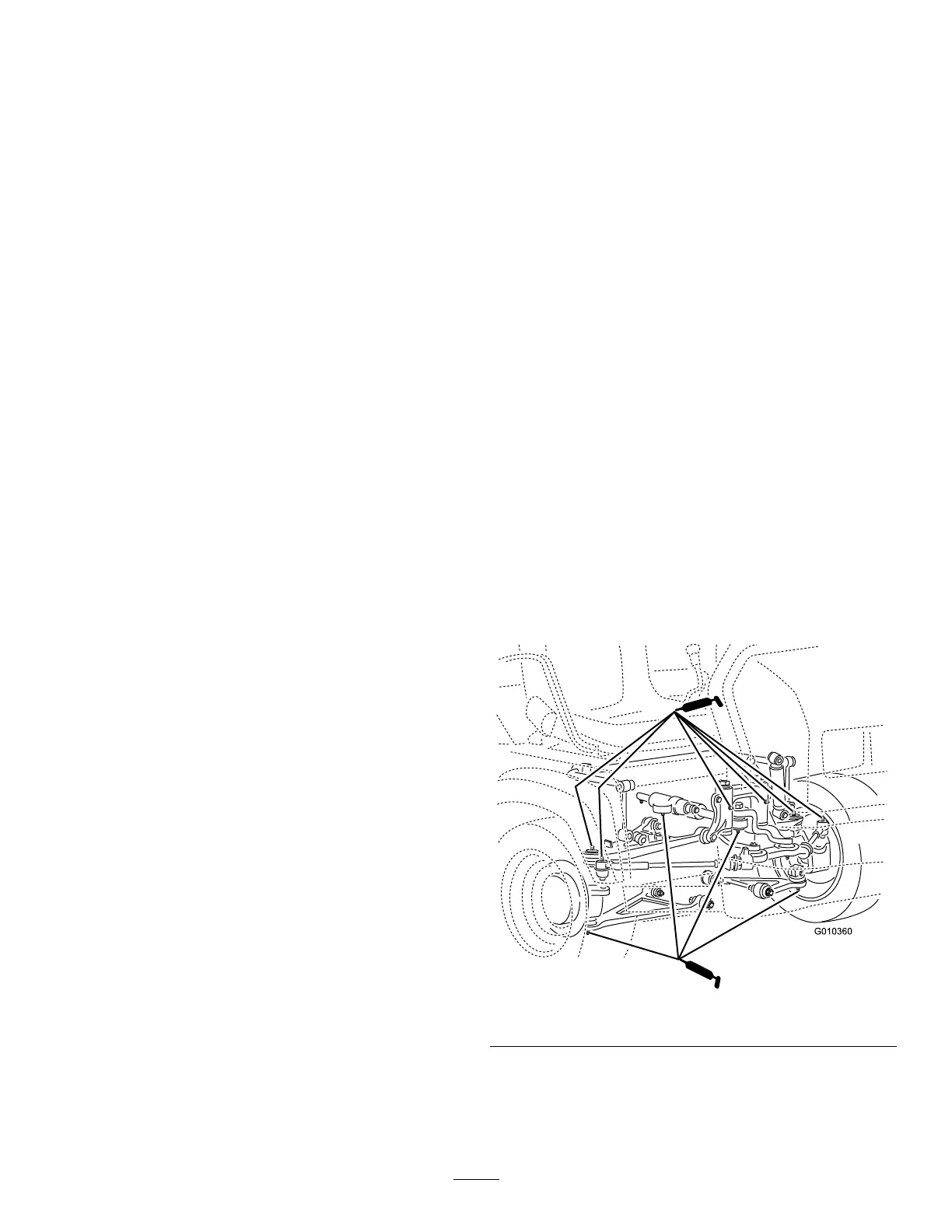

The grease tting locations and quantities are as

follows:

• Ball joints (4) ; refer to Figure 29

• T ie rods (2) ; refer to Figure 29

• Pivot mounts (2) ; refer to Figure 29

• Steering cylinder (2) ; refer to Figure 29

g010360

Figure 29

• Spring tower (2) ; refer to Figure 30

39

Loading...

Loading...