Adding Fuel

Use only clean, fresh diesel fuel or biodiesel fuels with

low (<500 ppm) or ultra-low (<15 ppm) sulfur content.

The minimum cetane rating should be 40. Purchase

fuel in quantities that can be used within 180 days

to ensure fuel freshness.

• Use summer grade diesel fuel (No. 2-D) at

temperatures above -7°C (20°F) and winter

grade (No. 1-D or No. 1-D/2-D blend) below that

temperature.

• Using winter-grade fuel at lower temperatures

provides lower ash point and cold-ow

characteristics, which eases starting and reduces

fuel-lter plugging.

Note: Using of summer-grade fuel above -7°C (20°F)

contributes toward longer fuel pump life and increased

power compared to winter-grade fuel.

Important: Do not use kerosene or gasoline

instead of diesel fuel. Failure to observe this

caution will damage the engine.

Using Biodiesel Fuel

This machine can also use a biodiesel blended fuel

of up to B20 (20% biodiesel, 80% petrodiesel). The

petrodiesel portion should be low or ultra-low sulfur .

Observe the following precautions:

• The biodiesel portion of the fuel must meet

specication ASTM D6751 or EN14214.

• The blended fuel composition should meet ASTM

D975 or EN590.

• Painted surfaces may be damaged by biodiesel

blends.

• Use B5 (biodiesel content of 5%) or lesser blends

in cold weather .

• Monitor seals, hoses, gaskets in contact with fuel

as they may degrade over time.

• Fuel lter plugging may be expected for a time

after converting to biodiesel blends.

• Contact your distributor for more information on

biodiesel.

Filling the Fuel T ank

Fuel-tank capacity: 22 L (5.85 US gallons).

1. Clean the area around the fuel-tank cap.

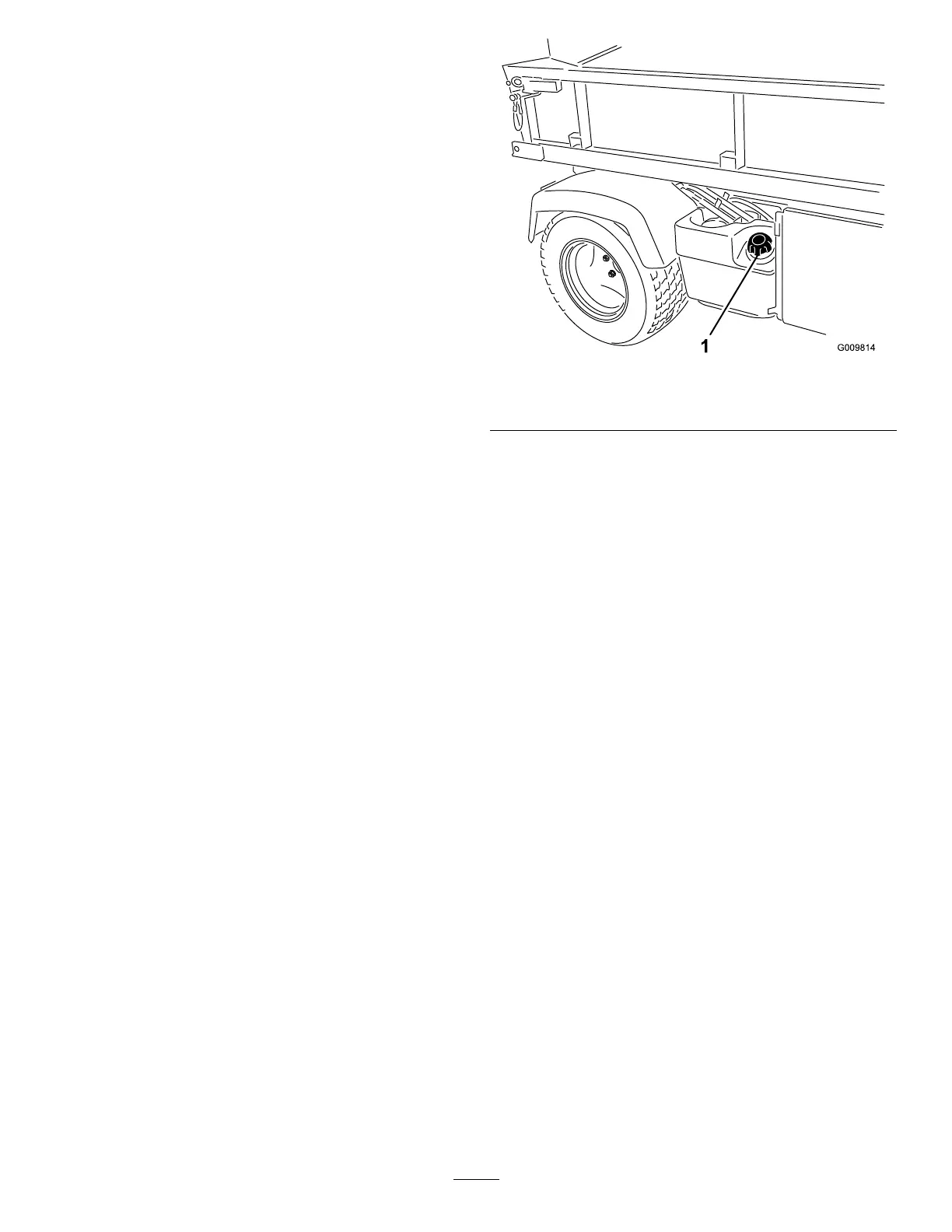

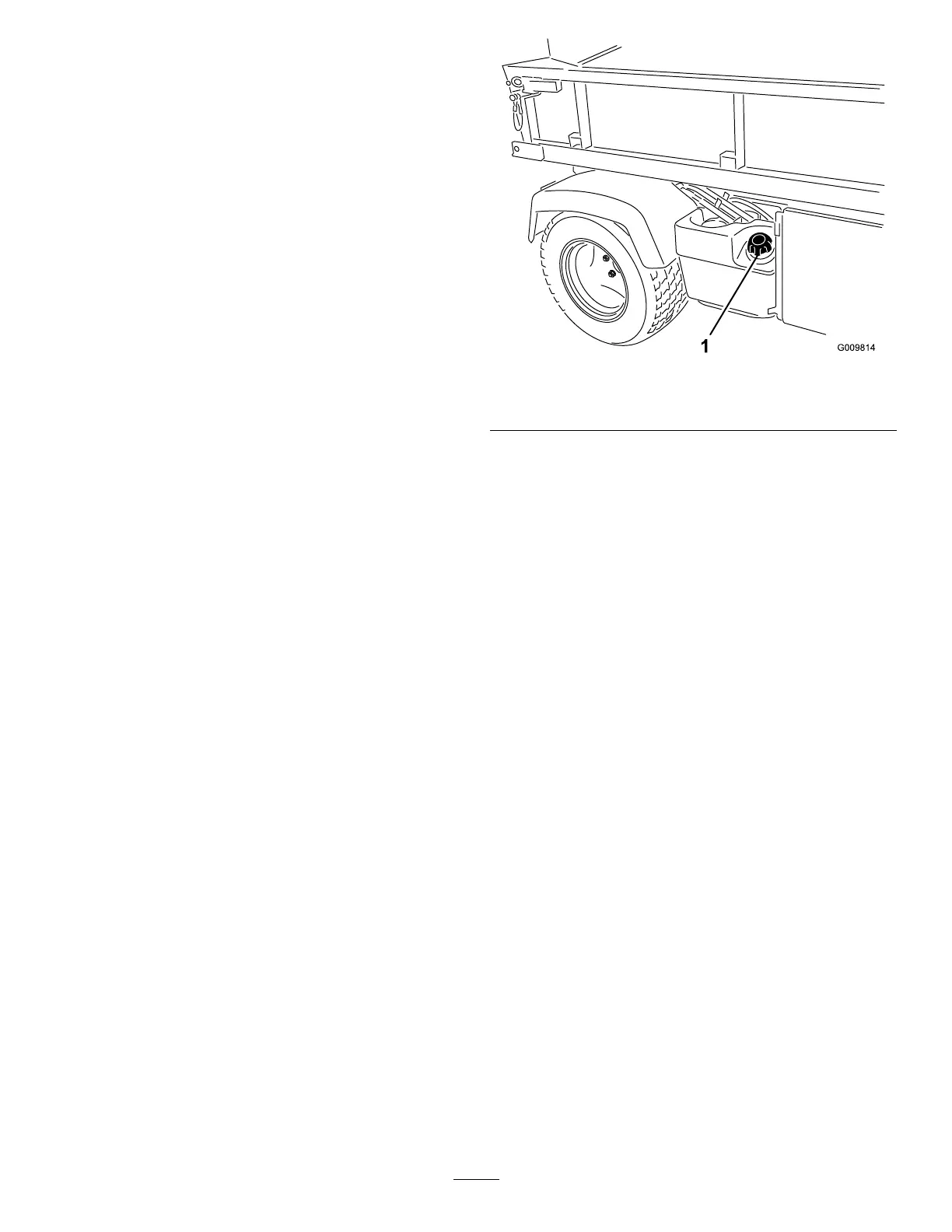

2. Remove the fuel-tank cap ( Figure 14 ).

g009814

Figure 14

1. Fuel-tank cap

3. Fill the tank slightly below the top of the tank,

(bottom of the ller neck), then install the cap.

Note: Do not overll the fuel tank with fuel.

4. Wipe up any spilled fuel to prevent a re hazard.

Breaking in a New Machine

Service Interval : After the rst 100 hours —Perform

the guidelines for breaking in a new

machine.

Perform the following to provide proper performance

for the machine:

• Ensure that the brakes are burnished; refer to 4

Burnishing the Brakes ( page 13 ) .

• Check the uid and engine-oil levels regularly .

Remain alert for signs that the machine or its

components are overheating.

• After starting a cold engine, let it warm up for about

15 seconds before using the machine.

Note: Allow more time for the engine to warm up

when operating in cold temperatures.

• V ary the machine speed during operation. A void

fast starts and quick stops.

• A break-in oil for the engine is not required.

Original engine oil is the same type specied for

regular oil changes.

• Refer to Maintenance ( page 32 ) for any special,

low-hour checks.

22

Loading...

Loading...