Workman MDX--D Page 6 -- 41 Chassis

Bleed Brake System

IMPORTANT: To prevent contamination of t he brake

system, make sure to clean components before dis-

assembly.

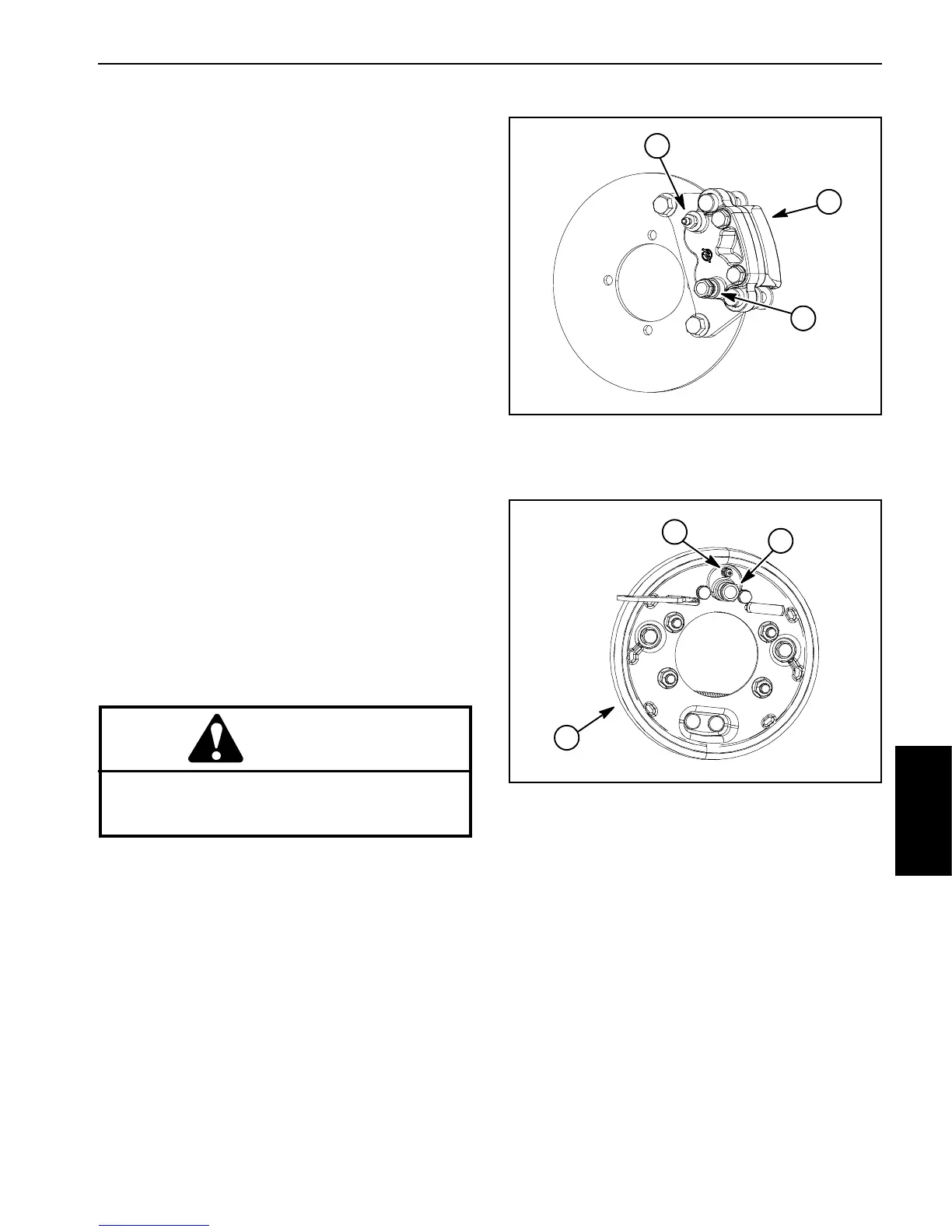

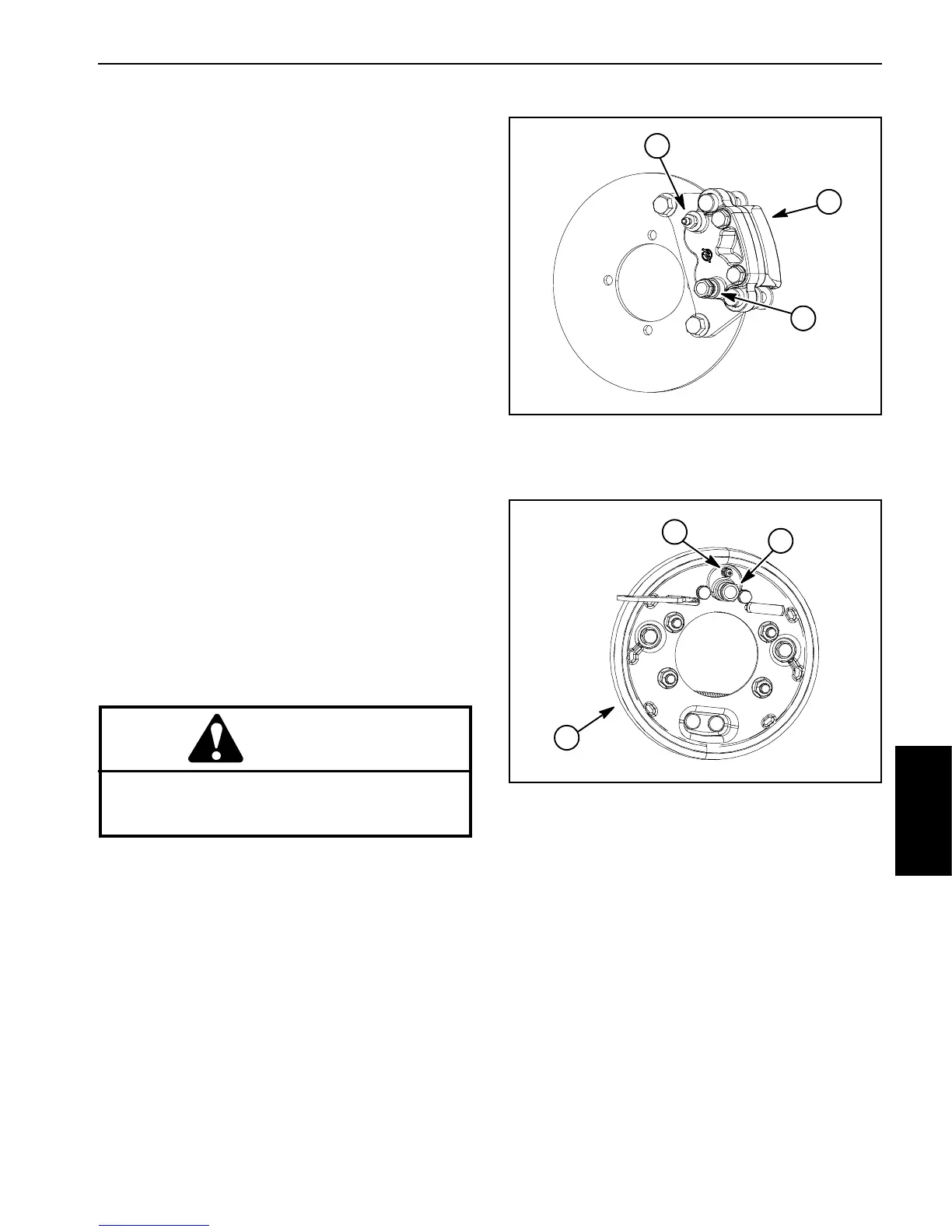

1. Connect a suitable transparent hose to bleeder valve

on front brake caliper (Fig. 31) or rear wheel brake cylin-

der (Fig. 32). Submerge other end of hose in a glass

container partially filled with clean brake fluid.

2. Have a second person pump brake pedal several

times, then hold pedal down firmly.

3. With pedal firmly depressed, open bleeder valve of

brake until pedal fades to floor. Close bleeder valve be-

fore releasing pedal.

4. Repeat procedure until a continuous flow of brake

fluid, with no air bubbles, is released from bleeder valve.

Make sure fluid level is maintained in brake fluid res-

ervoir at all times.

5. When brake bleeding is completed, torque caliper

bleed valve as follows:

A. Torque caliper bleed valve on front brakes from

54 to 66 in--lb (6.2 to 7.4 N--m).

B. Torque caliper bleed valve on rear brakes to 38

in--lb (4.3 N--m).

6. Repeat steps 1 to 4 for other front calipers and rear

brake cylinders.

CAUTION

After servicing the brakes, always check the

brakes in a wide open, level area that is free of

other persons and obstructions.

7. After bleeding of b rakes is completed, test vehicle to

make sure brakes are operating correctly and brake

pedal is solid.

1. Front caliper (LH shown)

2. Banjo bolt

3. Bleed valve

Figure 31

1

2

3

1. Rear brake (LH shown)

2. Banjo bolt

3. Bleed valve

Figure 32

1

2

3

Chassis

Loading...

Loading...