86

Joining Crankcase Halves

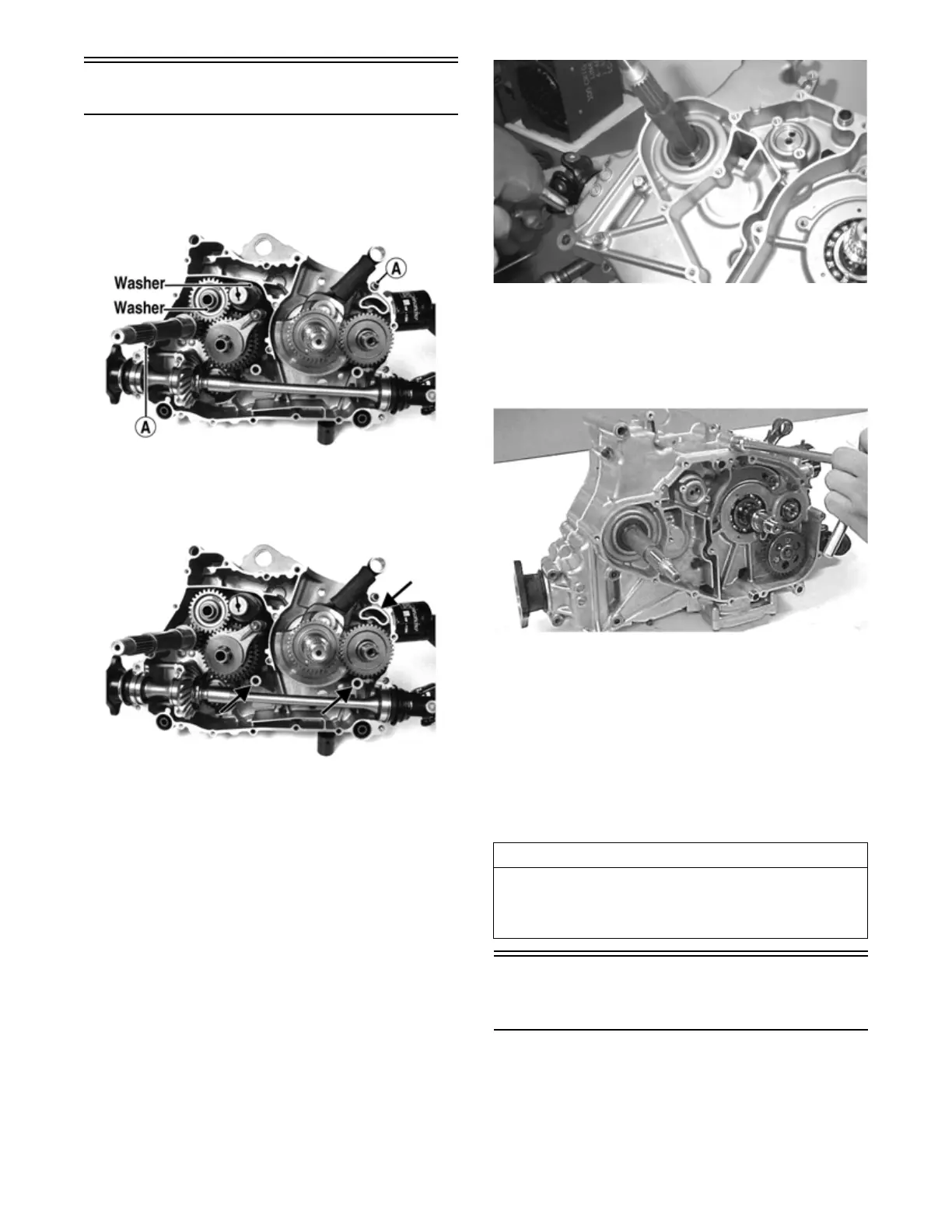

1. Verify that the two alignment pins (A) are in place

and that both case halves are clean and grease free.

Apply Loctite #5900 or suitable substitute sealant to

the mating surfaces. Place the left-side half onto the

right-side half.

FI639B

NOTE: Be sure to apply silicone to the inside radius

of all cap screw locations and the entire surface of the

internal cap screw bosses.

FI639D

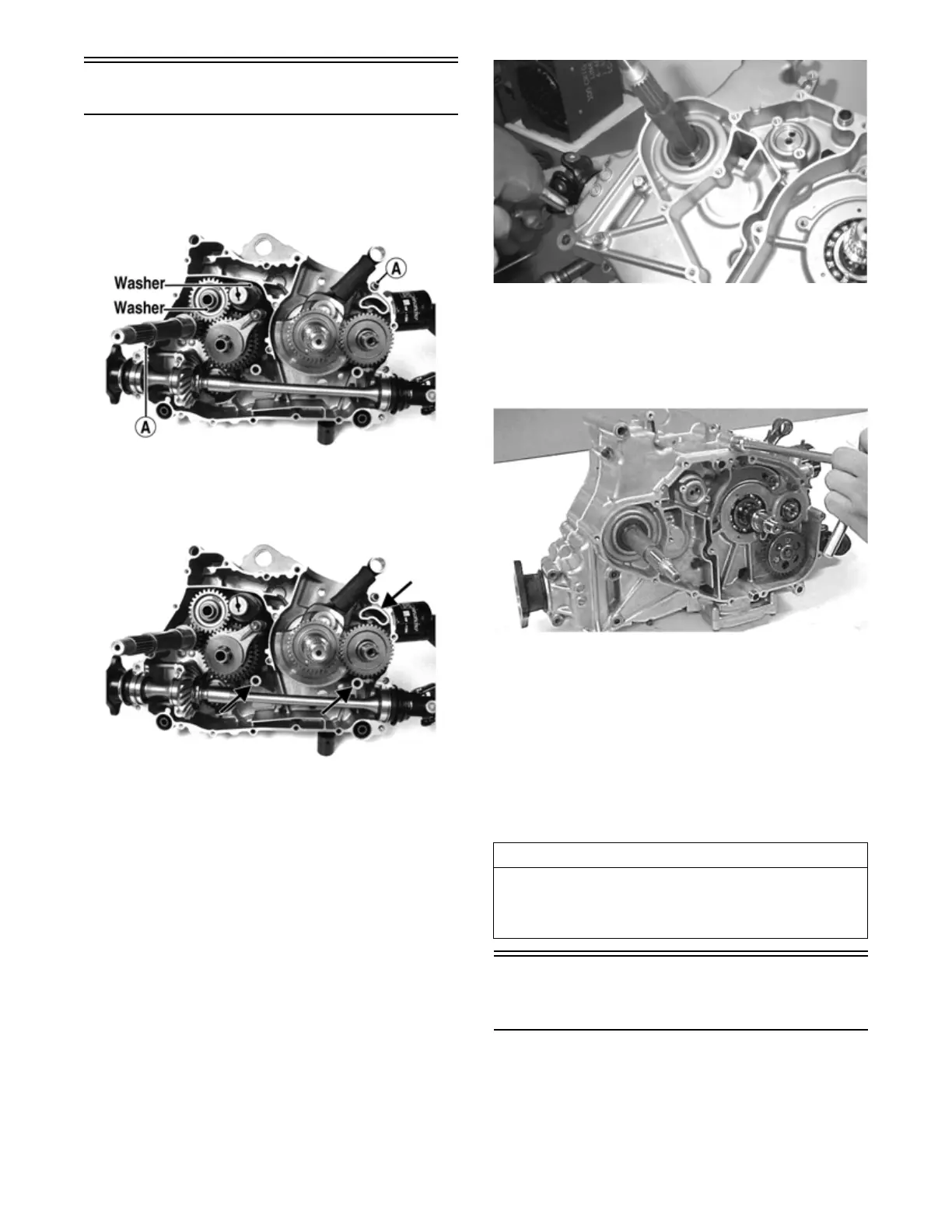

2. Using a plastic mallet, lightly tap the case halves

together until cap screws can be installed.

3. From the right side, install the crankcase cap screws

noting the location of the different-sized cap screws;

then tighten only until snug.

NOTE: Rotate the shafts back and forth to ensure

no binding or sticking occurs while tightening the cap

screws.

MD1008

4. From the left side, install the remaining crankcase

cap screws; then tighten only until snug.

NOTE: Rotate the shafts back and forth to ensure

no binding or sticking occurs while tightening the cap

screws.

CC871

5. In a crisscross pattern, tighten the 8 mm cap screws

until the halves are correctly joined; then tighten to

21 ft-lb (28.6 N-m).

NOTE: Rotate the shafts back and forth to ensure

no binding or sticking occurs.

6. In a crisscross pattern, tighten the 6 mm cap screws

to 10 ft-lb (13.6 N-m).

NOTE: Rotate the shafts back and forth to ensure

no binding or sticking occurs.

Installing Engine/

Transmission

NOTE: The manufacturer recommends new gas-

kets, patch-lock cap screws, lock nuts, and O-rings be

installed whenever servicing the vehicle.

AT THIS POINT

After completing center crankcase components, pro-

ceed to Installing Right-Side Components, to Installing

Left-Side Components, and to Installing Top-Side Com-

ponents.

Loading...

Loading...