CVHE-SVX005C-EN

65

10 to 13.8kV Medium Voltage Motor

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury.

Disconnect all electric power, including remote

disconnects before servicing. Follow proper lockout/

tagout procedures to ensure the power can not be

inadvertently energized. Verify that no power is

present with a voltmeter.

All electrical circuits shall be treated as energized until all

lockout/tagout procedures are in place and the circuit has

been tested to verify that it is de-energized. The medium-

voltage motor terminal box cover must NOT be removed if

power is present, or if there is a possibility that power may

be present. Working on energized medium-voltage circuits

is not an approved practice for normal HVAC maintenance

or service.

The motor is suitable for remote-mounted across-the-line

(including circuit breaker starting), primary reactor,

autotransformer, or solid-state starting. Refer to the unit

nameplate for motor data including RLA, LRA, etc.

In all cases of non-Trane supplied starters, a disconnecting

means and short-circuit protection must be installed ahead

of the starter, unless they are included as part of the starter.

Note: Trane assumes no responsibility for the design,

documentation, construction, compatibility,

installation, start-up, or long term support of starters

provided by others.

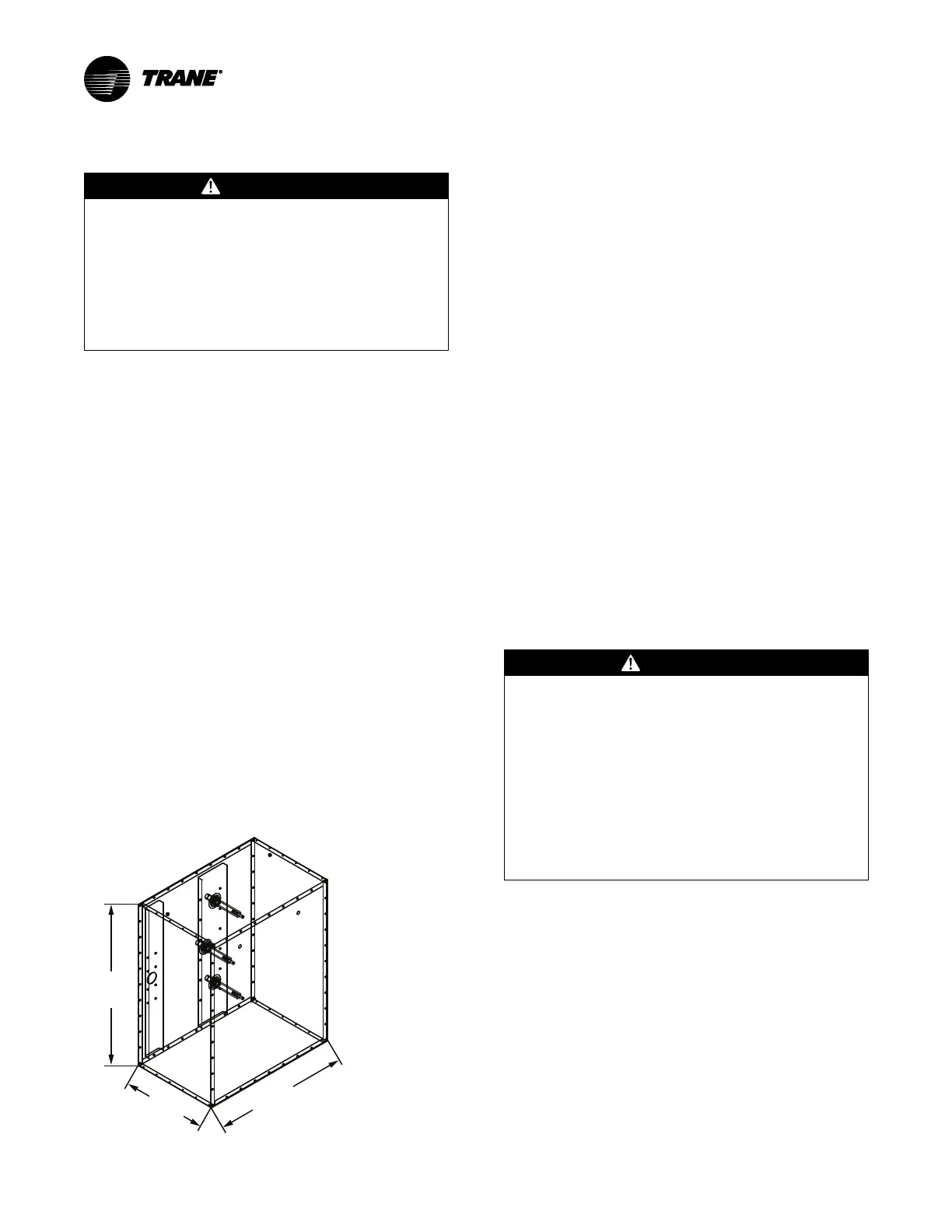

Motor Terminal Box

A large steel motor terminal box is provided to allow for the

field connection of the motor power supply wire to the

motor.

Figure 44. Motor terminal box dimensions, in. (mm)

• Motor terminal box cover-only weight is 55 lb (25 kg).

• Two 7/8-in. (22.225 mm) lifting holes are provided in

the cover.

• Motor terminal box weight without the cover is 215 lb

(97.5 kg).

• Two 3/8-in.–16 weld nuts are provided on the top of the

terminal box to allow the use of properly rated lifting D-

rings if removal is needed for clearance purposes.

Note: If the box is removed for installation purposes,

the motor terminals MUST be protected against

impact or stress damage. Field fabrication of a

cover or guard is required.

• The motor terminal box is large enough to

accommodate the use of stress cones.

• If conduit is applied, a flexible connection of the conduit

to the box should be made to allow for unit

serviceability and for vibration isolation. The cable

should be supported or protected against abrasion and

wear on any edges or surfaces. Cable or conduit

openings can be cut at any location in the box sides,

top, or bottom for cable entry. Always ensure that NO

debris remains in the box after cutting cable entry

holes.

Motor Supply Wiring

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury.

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements

for field wiring installation and grounding as

described in NEC and your local/state/national

electrical codes.

Motor circuit wire sizing by the installer must be made in

accordance with the National Electric Code (NEC) or any

other applicable codes. All wiring to the CenTraVac™

chiller motor must be shielded copper, with insulation rated

to a minimum of 15kV.

Three terminals are provided on the chiller for the

connection of power to the motor from the starter. Power

leads to motors must be in multiples of three, with equal

phase representation in all conduits or wire trays. To limit

the effects of corona or ionization with cables carrying more

than 2000V, Trane requires that the power cable have a

metallic shield, unless the cable is specifically listed or

approved for non-shielded use. If the cable is shielded, the

shielding must be grounded at one end (grounding is

typically done at the starter or supply end).

Loading...

Loading...