CVHE-SVX005C-EN

89

Table 21. Recommended maintenance (continued)

(b)

Contact a qualified service organization to determine when to conduct a complete examination of the unit to discern the condition of the compressor and internal

components. Check the following: chronic air leaks (which can cause acidic conditions in the compressor oil and result in premature bearing wear) and evaporator or

condenser water tube leaks (water mixed with the compressor oil can result in bearing pitting, corrosion, or excessive wear).

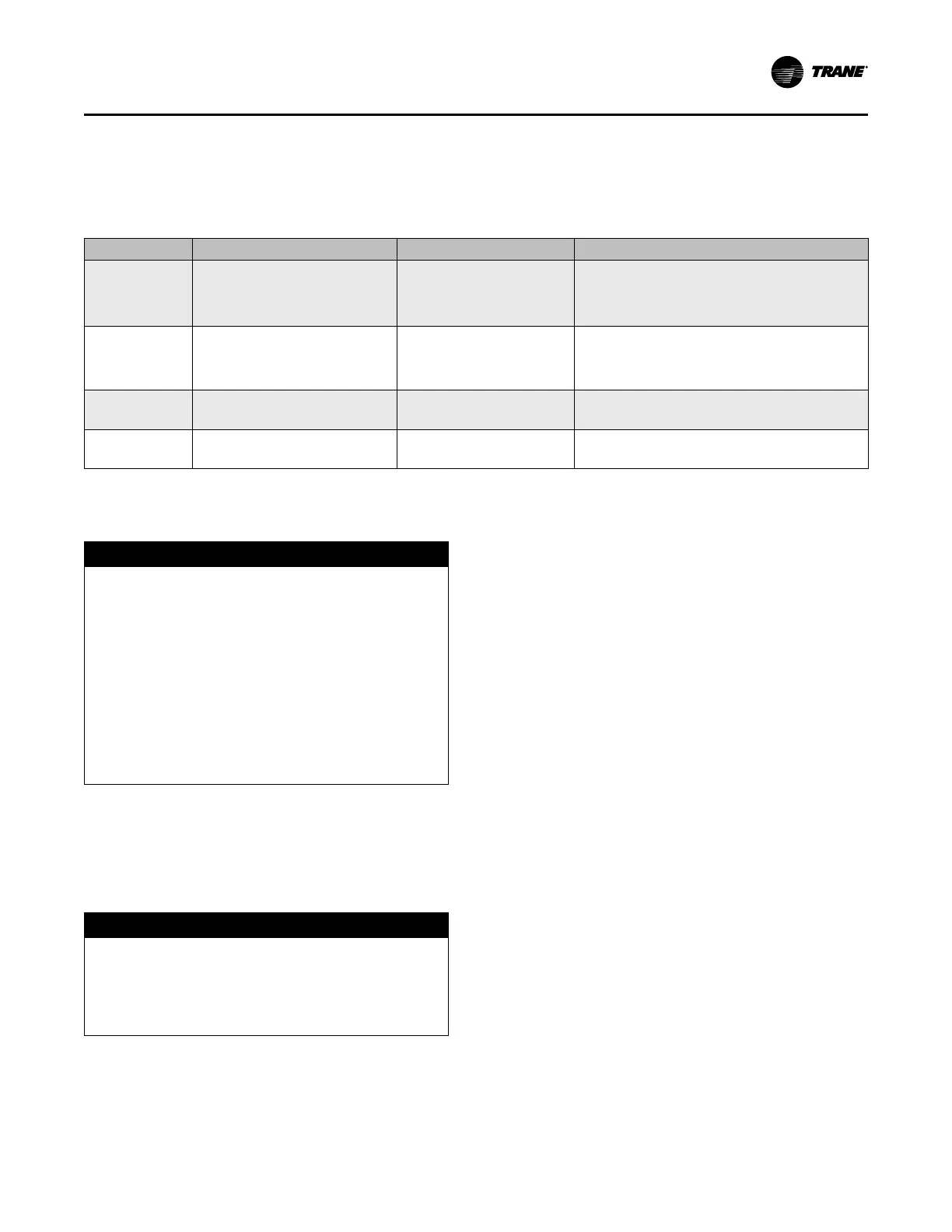

Table 22. Recommended maintenance of optional features

Feature

Every 3 months Every 6 months Annually

Waterbox Coatings

Inspect waterbox coatings within the first 1–

3 months to determine a required

maintenance schedule for your job site. Refer

to “Waterbox and Tubesheet Protective

Coatings,” p. 92 for more information.

Waterbox Anodes

Inspect waterbox anodes within the first 1–

3 months to determine a required

maintenance schedule for your job site. Refer

to “Sacrificial Anodes,” p. 92 for more

information.

Gantries

Lubricate the gantries annually. Use ConocoPhillips MegaPlex®

XD3 (gray in color), LPS® MultiPlex Multi-Purpose (blue in color),

or equivalent.

Hinges

Lubricate the hinges annually. Use ConocoPhillips MegaPlex®

XD3 (gray in color), LPS® MultiPlex Multi-Purpose (blue in color),

or equivalent.

Recommended Compressor Oil

Change

NOTICE

Equipment Damage!

Mixing refrigerants or oils could result in equipment

damage including bearing damage, introduction of

acids into the chiller, or continuous purge pump-out

in high-head/high ambient applications.

CenTraVac™ chillers are manufactured with different

refrigerant/oil systems: 1) chillers using R-123

refrigerant and OIL00022 compressor oil, and 2)

chillers using R-514A refrigerant and various Trane

POE-based compressor oils.

Always verify proper refrigerant and oil for your

chiller. Do NOT mix refrigerants and oils.

This Installation, Operation, and Maintenance manual

applies to CenTraVac™ chillers with two different

refrigerant and compressor oil systems:

• R-123 refrigerant and OIL00022 compressor oil.

• R-514A refrigerant and Trane OIL00379/OIL00380

compressor oil.

NOTICE

Equipment Damage!

Failure to follow instructions below could result in

equipment damage.

Follow oil use instructions for post-service

compressor air-run procedures.

For post-service compressor air-run procedures on

CenTraVac™ chillers that use R-514A refrigerant and POE

oil:

1. Use Trane OIL00381/OIL00382 compressor oil for the

air-run procedure.

2. Upon completion of the air-run procedure, drain the

OIL00381/OIL00382 from the sump.

3. After unit final assembly and evacuation, refill the sump

with Trane OIL00379/OIL00380.

Important: Verify proper refrigerant and compressor oil for

your chiller before proceeding!

After the first six months of accumulated operation or after

1000 hours operation—whichever comes first—it is

recommended to change the oil and filter. After this oil

change, it is recommended to subscribe to the Trane

annual oil analysis program rather than automatically

change the oil as part of scheduled maintenance. Change

the oil only if indicated by the oil analysis. Using an oil

analysis program will reduce the chiller’s overall lifetime

waste oil generation and minimize refrigerant emissions.

The analysis determines system moisture content, acid

level, and wear metal content of the oil, and can be used as

a diagnostic tool. The oil analysis should be performed by a

qualified laboratory that is experienced in refrigerant and oil

chemistry and in the servicing of Trane® centrifugal

chillers.

In conjunction with other diagnostics performed by a

qualified service technician, oil analyses can provide

valuable information on the performance of the chiller to

help minimize operating and maintenance costs and

maximize its operating life. A valve is installed next to the

oil filter for the purpose of obtaining oil samples.

Recommended Maintenance

Loading...

Loading...