4.2. INSPECTION

Before and after disassembly,inspect each part

for the items mentioned below.Parts which

deviate from the specified values should be

replaced.

-Wash clean all disassembled parts and check them for

wear,damage,deformation,Burning ,etc. Defective parts

should be corrected or replaced.

-As the drive pinion and the ring gear make a pair,they

should be replaced together even if only one is found to

be defective.

-Backlash between the drive pinion and the ring gear

0.1-0.2 mm

(0.004-0.008 in)

Backlash

-Backlash between the diff-pinion and the dif-side gear.

0.1-0.2 mm

(0.004-0.008 in)

Backlash

-When the backlash exceeds 0.5mm,also inspect the

thrust collar for wear,defective collars should be

replaced.

-Disengaging the resistance of PTO shifters.

17 Kgf (38 lbs)Usable limit

18-22 Kgf (40-49lbs)Standard Value

* Measured at the shifter

4.3. REASSEMBLY

Reassemble the parts in reverse order of disassembly,

following these instructions.

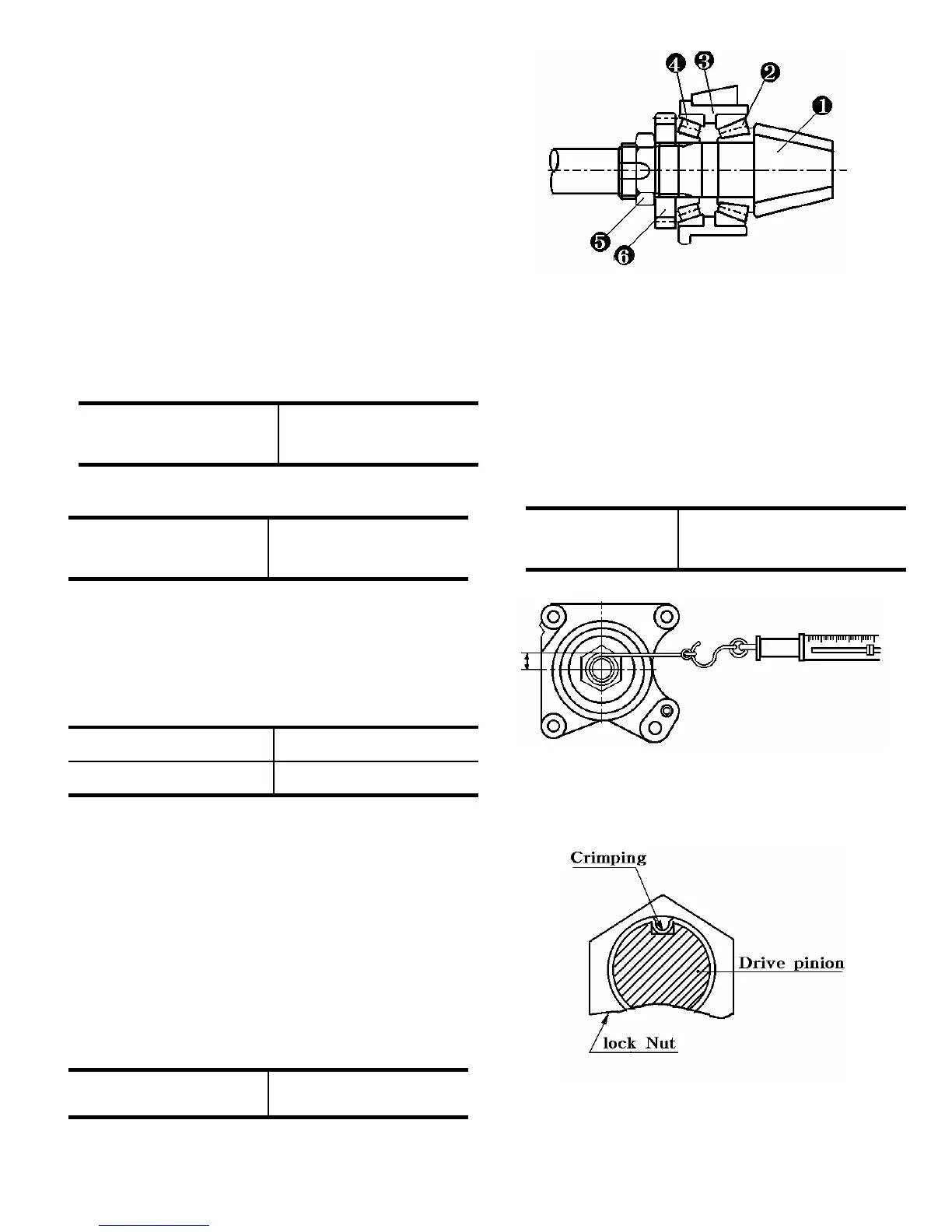

(1) Ring gear,Drive pinion,and related parts.

a. Apply oil to the drive pinion and related parts

ahead of time.Then install them and tighten the

assembly to the specified torque.

1.4 Kgf.m (9.36 ft.lbs)Tightening torque

(1) Drive pinion

(2) Tapered roller bearing

(3) Drive pinion metal

(4) Tapered roller bearing

(5) Nut (M30X1.0)

(6) Gear

b.Be sure that the starting torque of the

drive pinion meets the specified level.

0.11-0.13 Kgf.m

(0.792-0.936 ft.lbs)

Starting torque

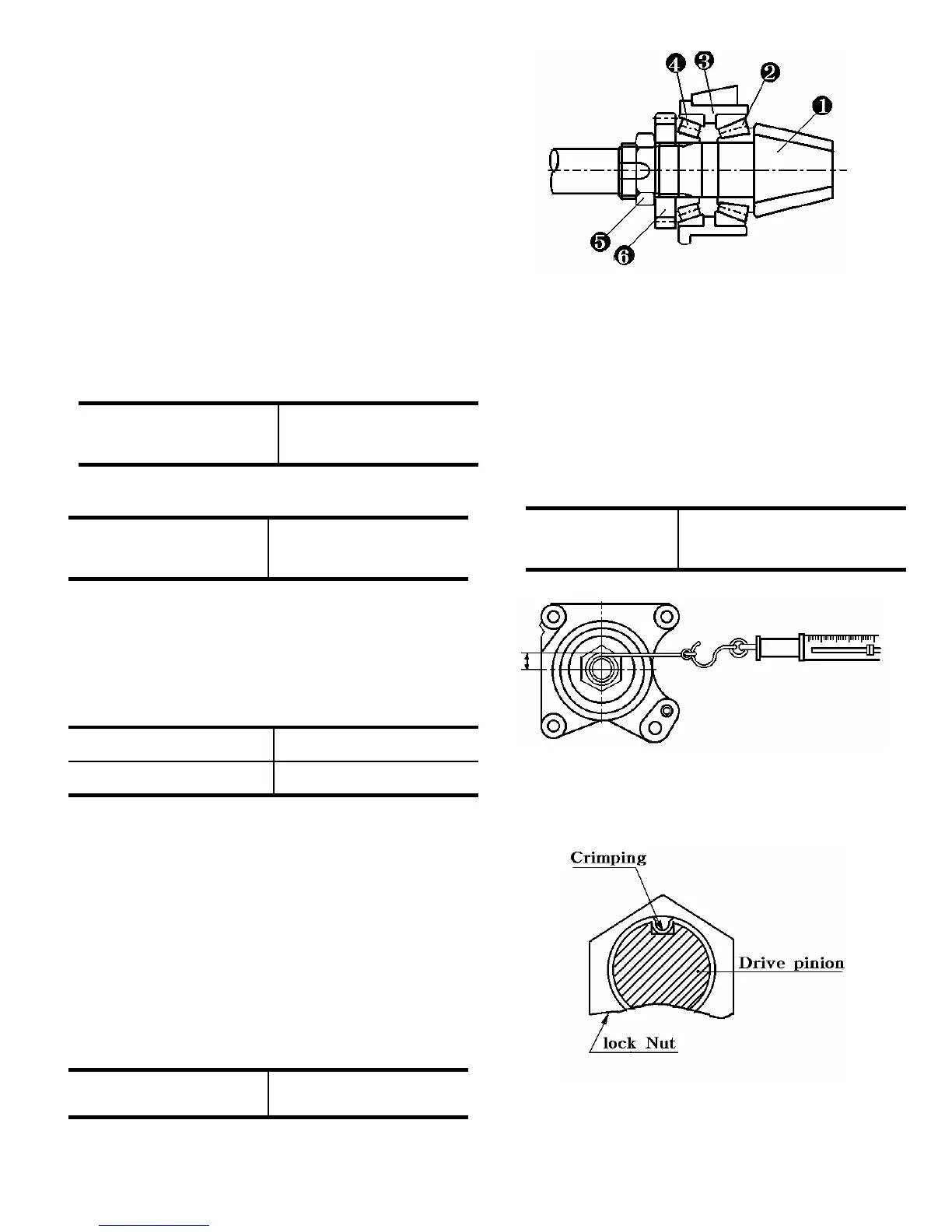

c. After the starting torque has been

adjusted to the specified level,crimp the

lock of the nut at one point as illustrated.

d. Tighten the drive pinion metal(support)

by providing it with the same shimming

thickness that it had when it was

disassembled.

5-32

Fig.5-60

Fig.5-61

Fig.5-62

Loading...

Loading...