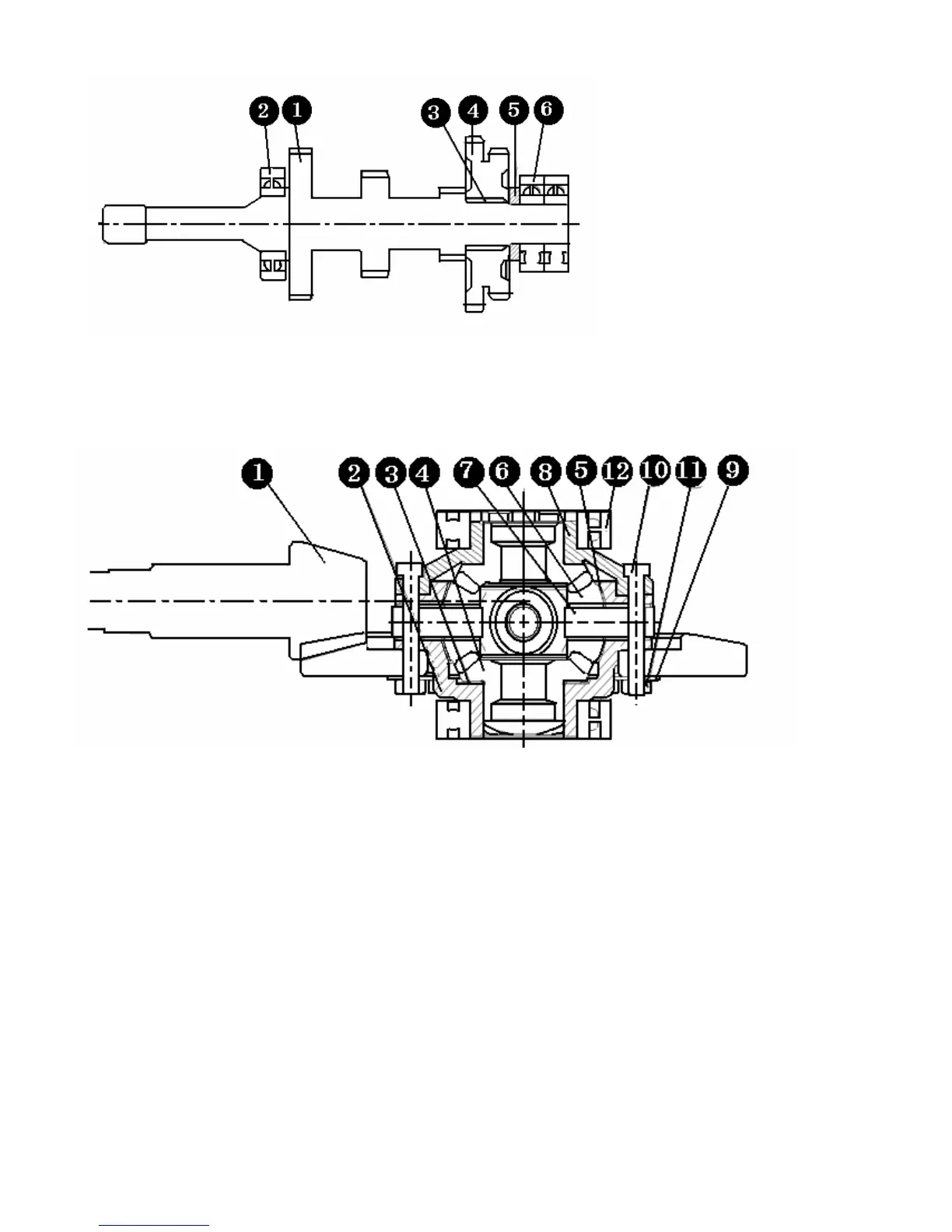

(8). Sub change counter shaft

1.Gear range(13X20X29T)

2.Ball bearing(6207)

3.Needle bearing

4.Gear spur(30X35T)

5.Washer(25X46X07)

6. Ball bearing(6305)

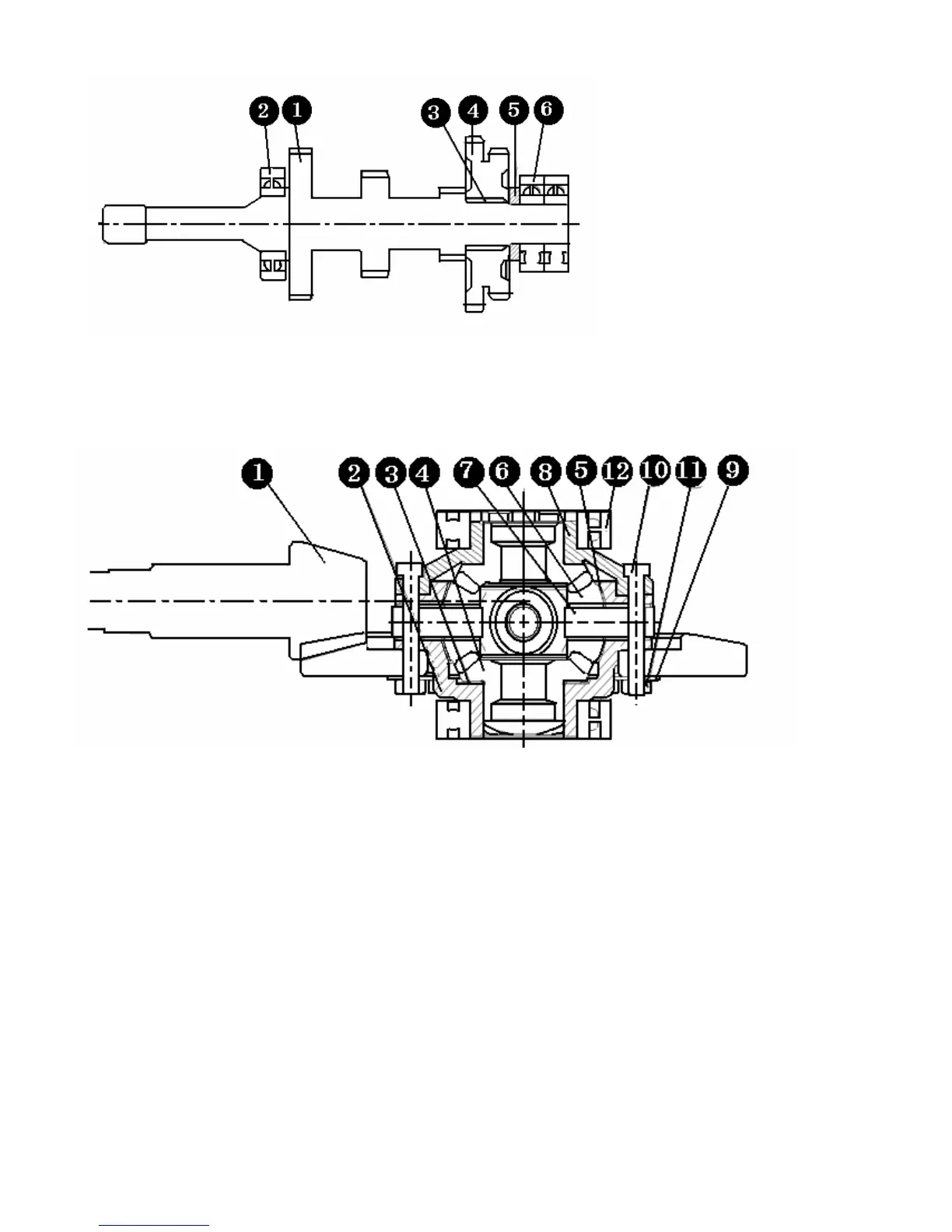

8.Differential gears.

Note:

1.Apply grease when installing Needle bearing

2.pay attention to the installed direction of gear(spur/30-35)

3.After installation,be sure to slide smoothly

1.Bevel 10X51 2.Case Diff(L) 3.Gear bevel(20) 5.Thrust collar,pinion

6.pinion Diff(12) 7.Shaft diff pinion 8.Case Diff (R) 9.plate lock

10.Bolt,differential 11.Nut 12.Ball bearing(6011)

Note:

1.When assembling without replacing the pinion gear and ring gear with new ones,provide the

same shimming thickness as that provided before disassembly.

2.Backlash between dif-pinion and dif-side gear should be within as range of 0.1 to 0.2mm

(0.004-0.008 in) and these parts should turn smoothly.

3.When reassembling the used pinion and ring gear,reinstall the same thickness of shims as was

installed before disassembly in each shimming position.

4.Backlash adjustment between the drive pinion and the ring pair(Fig5-8) i.As the drive pinion

and the ring gear make a pair,be sure not to mate them with other parts from differential

tractors.

5.Adjust the shimming to backlash of 0.1-0.2 mm (0.004-0.008 in). The standard shimming is

0.4mm (0.016 in) on both sides.

5-44

Fig.5-85

Loading...

Loading...