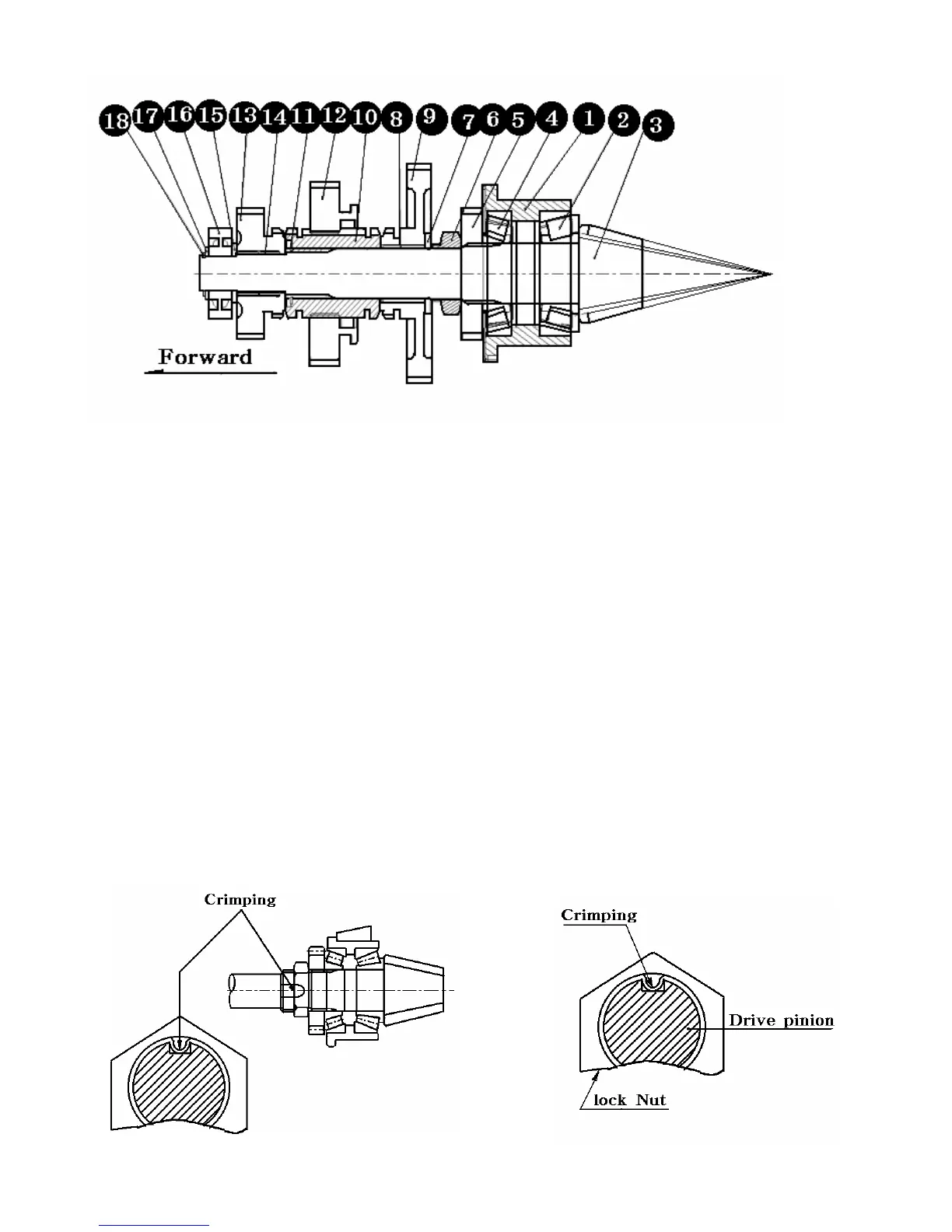

(7) Drive pinion Sub assembly

Note:

a.Apply oil to the drive pinion and related parts ahead of time.Then install them and tighten the

assembly to the specified torque.

b.Be sure that the starting torque of the drive pinion meets the specified level.

Starting torque is 0.11-0.13 Kgf.m (0.792-0.936ft.lbs)

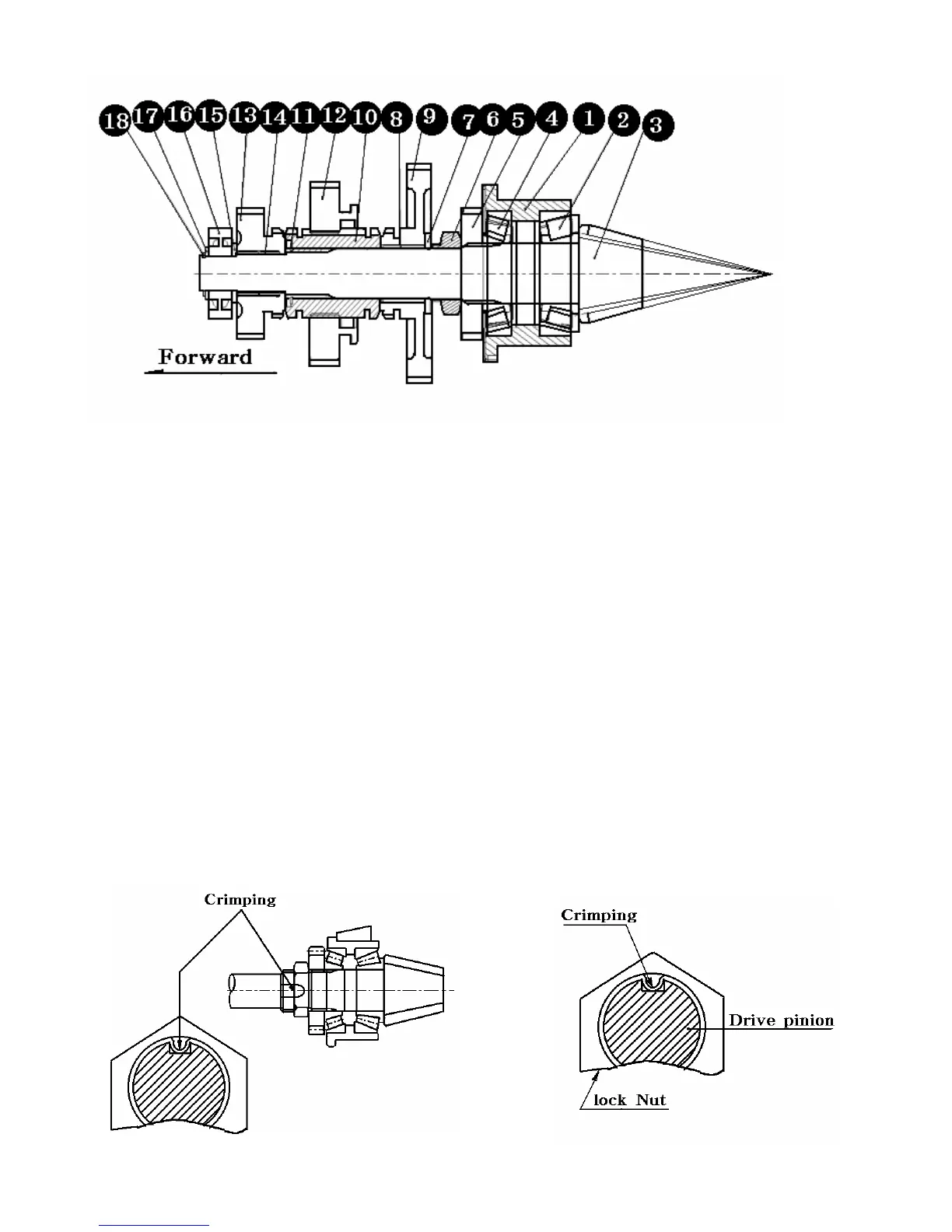

c.After the starting torque has been adjusted to the specified level,crimp the lock of the nut at one

point as illustrated.

d. Be sure that these parts should turn smoothly

When the drive pinion or the ring gear has been replaced, the proper number of shims to be installed

should be determined based upon the following procedure:

1.Metal pinion 2.Taper roller bearing 3.pinion drive 10 4.Taper roller bearing

5.Gear spur 23T 6.Nut(M30X1.5) 7.Washer(28X46X03) 8.Needle bearing

9.gear spur 40T 10.Hub(28X51X59) 11.Snap ring (shaft) 12.Gear spur 33T

13.gear helical 22T 14.needle bearing 15.Washer(20X34X03) 16.Ball bearing

17.Washer(20X30X1.8) 18.Snap ring (shaft)

5-43

Fig.5-83

Fig.5-84

Loading...

Loading...