Note:

Be sure to replace any clutch disc which has

0.2mm (0.008in) or less in rivet suppression.Use of

a insufficient rivet depression disc will result in

serious damage to the flywheel and the pressure

plate.

2) Any oil stained clutch disc must be replace.

However,a very small oil stain may simply be

removed by use of a volatile solvent.

Note:

The causes of oil stains must be located and

necessary corrective measures must be taken.

3) Hardened lining surfaces must be repaired by

use of a sandpaper,or be replaced with a new

ones.

4) When loose rivets are found,replace the clutch

disc assembly because those of rivets will loosen

again even if they are retightened.

5) Install the disc on the input gear and inspect the

rotational play.If the measurement deviates from

the specified value,replace the disc.

0.3mm(0.012in)

Usable limitRotational play of

the hub spline

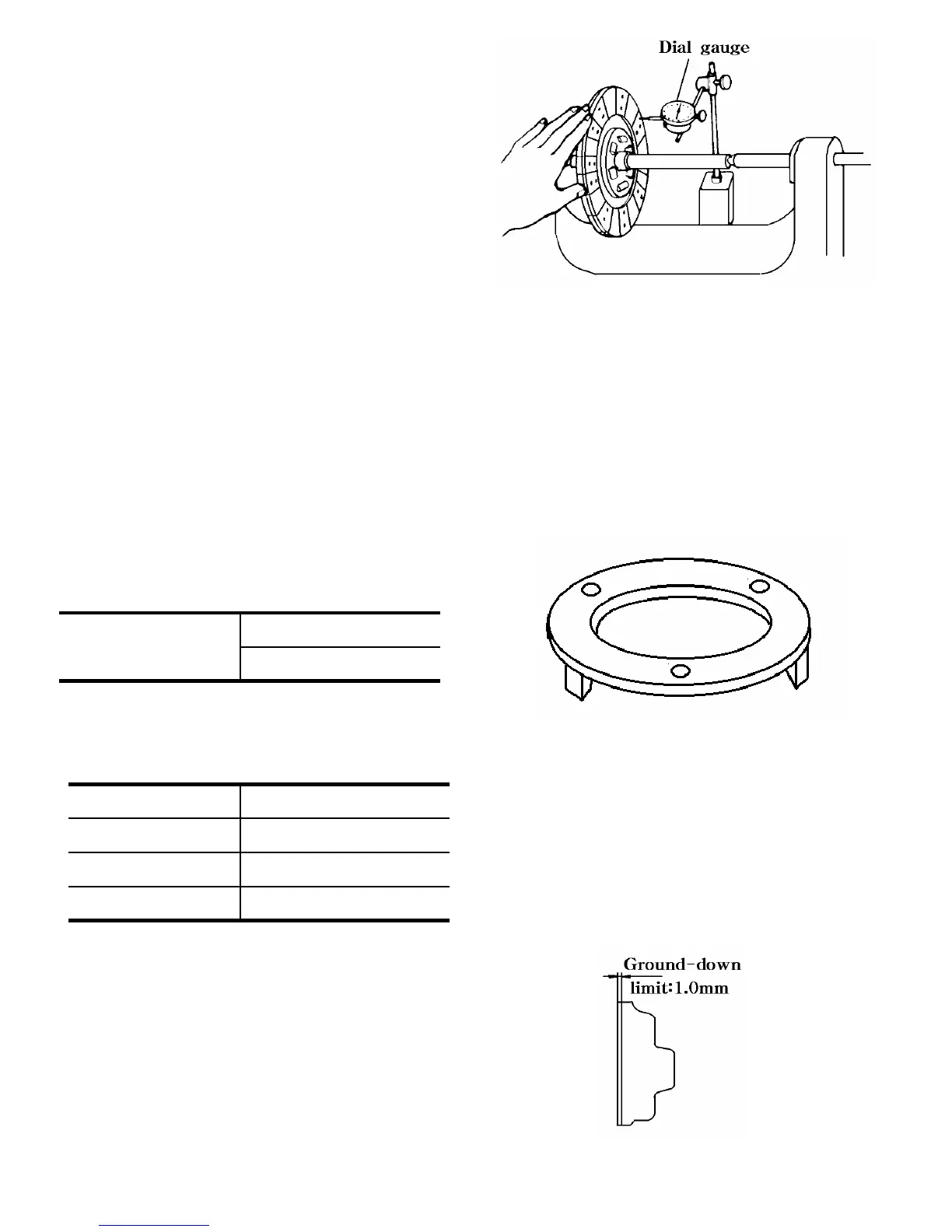

6) Measure the deviations of the clutch disc.If the

measurements are beyond the usable

limits,replace the clutch disc assembly.(Fig4-9)

0.7mm(0.028in) or lessLateral deviation

1.0mm(0.039in) or lessVertical deviation

Surface deviation 0.4mm(0.016in) or less

Usable limit

Fig.4-9

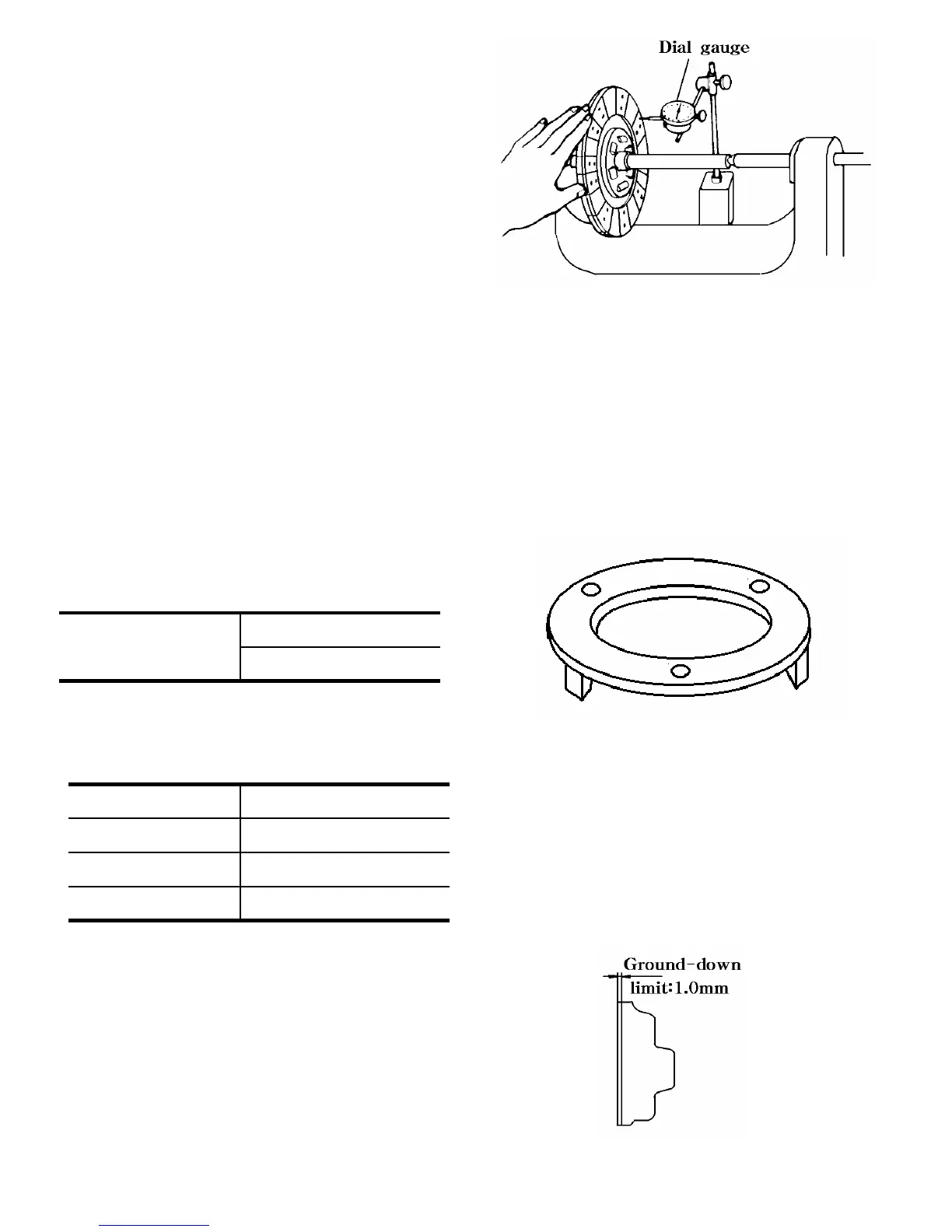

(2) Inspection of pressure plate

Inspect the pressure plate friction surface for up-

and down,scratches,stepped wear,or oil stains.

1) Shallow scratches may be repaired with a sand

paper,but excessive wear or damage must be

repaired by machining the friction surface.

Fig.4-10

2) Repair of friction surface.

The friction surface should be ground down or

machined to finish it to 12 ㎛(4.7X10¯4) to 25 ㎛

(9.8X10 ¯4) in surface smoothness.

The machining limit of the pressure plate surface

in thickness is 1.0mm(0.039in)

Fig.4-11

4-5

Loading...

Loading...