149

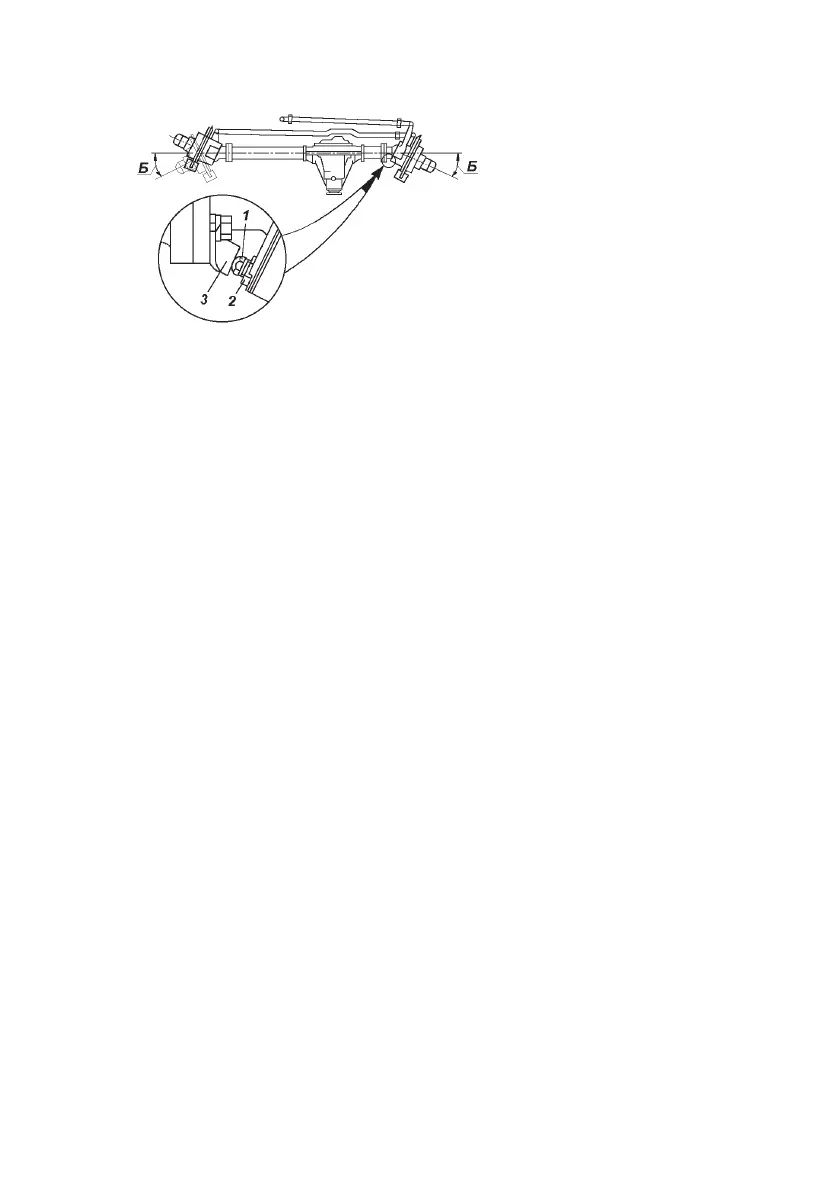

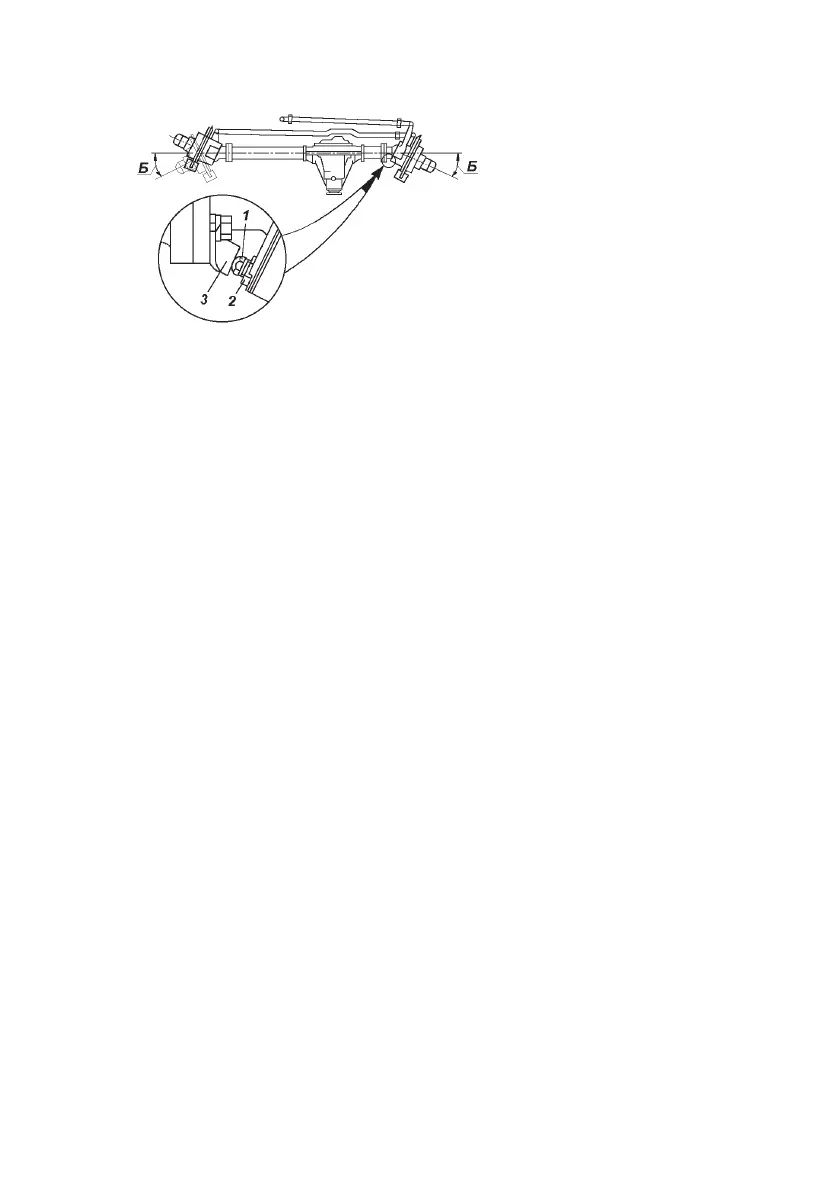

Fig. 9.16. Adjustment of the

wheels steering angle:

1 — steering stop bolt; 2 — lock-nut;

3 — steering stop.

and of the left wheel to the left should be within the limits of

31–32°. The increased steering angle of the wheels results in the

contact of the wheel with the suspension parts.

It is not required to add grease into the spherical pins and into

the ball struts during operation. The grease in the units is replaced

during maintenance.

Adjustment of steering knuckle pins 2 (Fig. 9.17) tightening at

works is carried out at pre-load along the common axle shaft of the pins.

During operation of the vehicle, pay special attention to the

condition of the tightening of the steering knuckle pins. At the

wear of the interacting spherical surfaces of liners 3 or pins 2 the

pre-load disappears and the air gap appears along the common axle

shaft of the pins.To remove the air gap tighten clamping bush 10.

Operating the front driving axle with gaps in the pins units can

lead to a premature failure of the liner of the upper pin.

It is easier to tighten clamping bush 10 of the lower pin while

in operation:

– unscrew nut 13;

– remove shield 12 with spacer 11;

– using the special wrench tighten clamping bush 10 to remove

the air gap (hit the threaded end of the pin with a copper hammer

beforehand);

– by turning the wrench by 10–20°, tighten this bushing to obtain

a preliminary tension along the common axle shaft of the pins;

– install bracket with a spacer;

– tighten nut (see Annex 2). Warning! Tightening torque excess

will cause lower pre-load and pin unit failure.

Loading...

Loading...