148

The motor vehicle may be equipped with non serviceable pro-

peller shafts (without grease tting). If this is the case, regularly

check shaft coupling pleated sleeve. Following pleated sleeve

damage, apply to the service centre for replacement.

Driving axles

Check the oil level in the housing, it should reach the lower

edge of the ller orice.

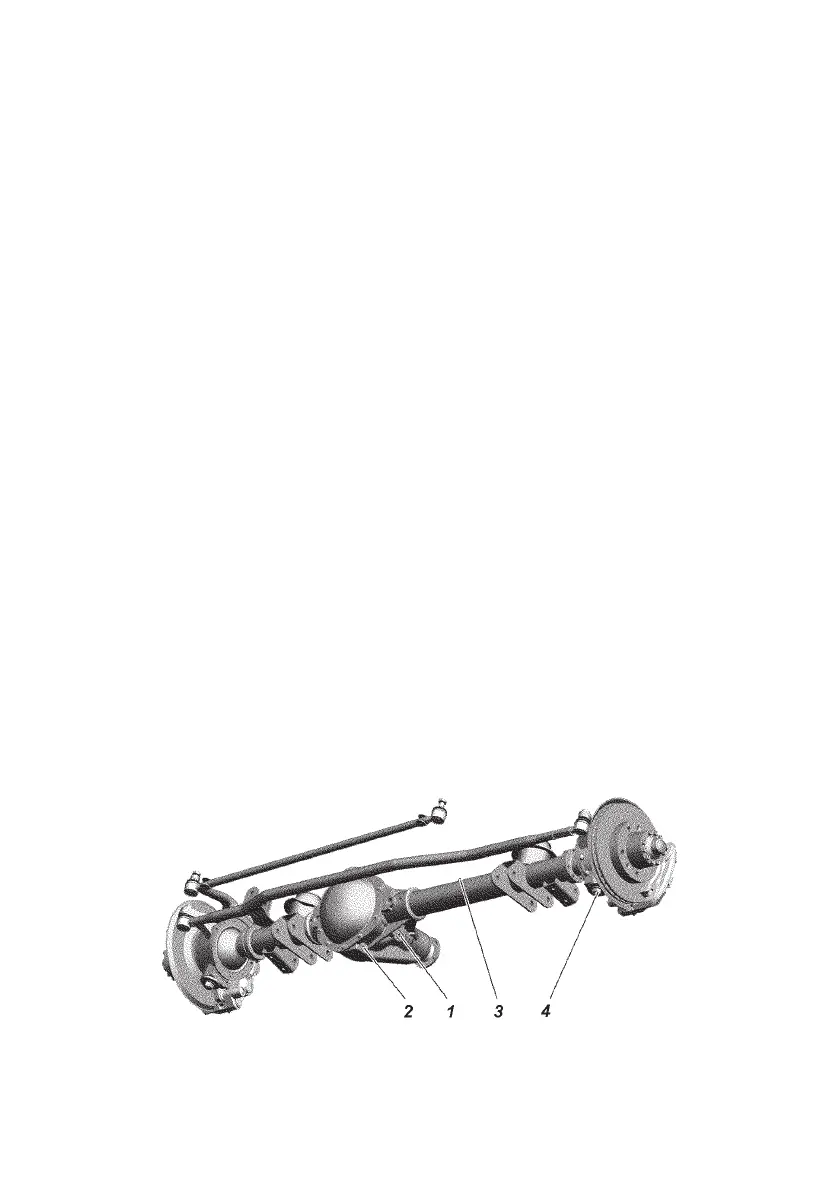

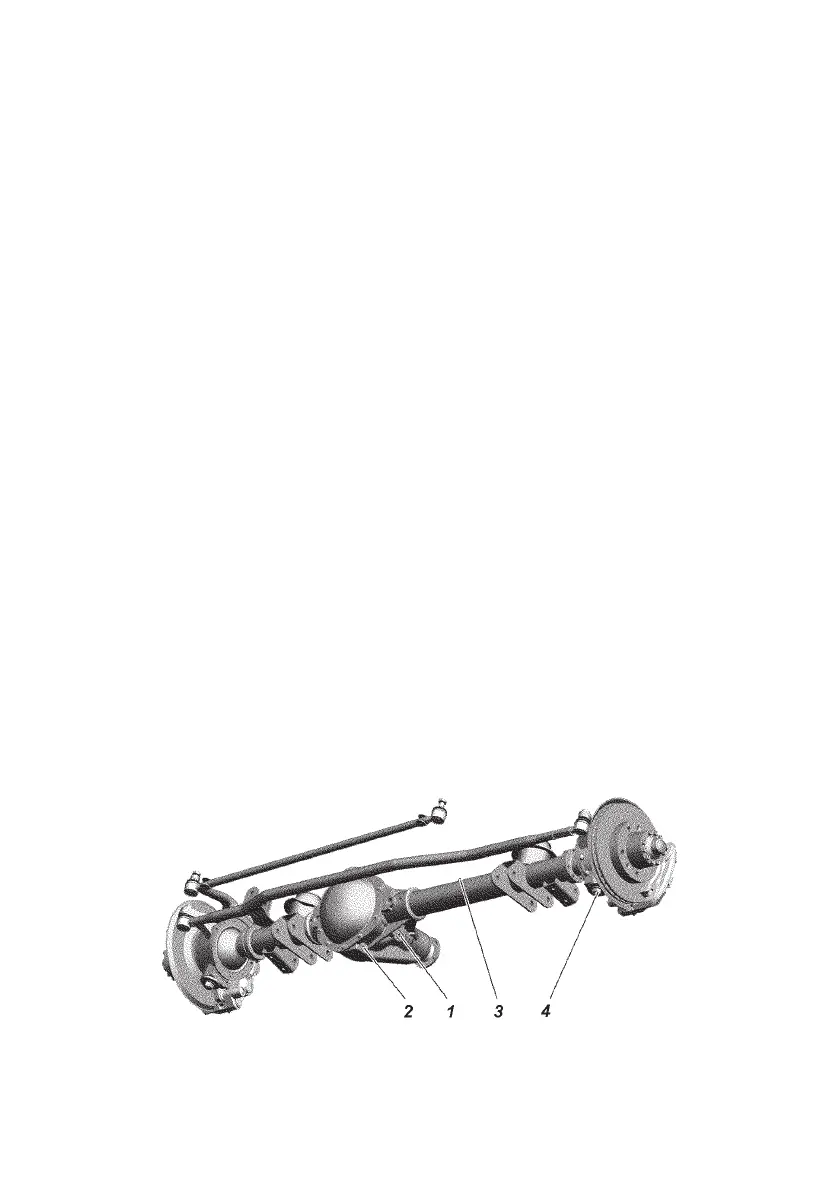

Drain the oil through orice 2 (Fig. 9.15) at the bottom of the

housing by screwing out ller plug 1.

Axial clearance over 0.05 mm in the bearings of the axle drive

pinion is not permitted, as greater clearance would provoke pre-

mature gear teeth wear and that could result in an axle jam. Check

the axial clearance in the bearings by swinging the drive pinion

by universal-joint ange.

Axial clearance in the differential bearings of the nal gear is

not allowed. Check the clearance by swinging of the drive pinion

when the housing cap is removed.

If a gap is detected, the axle should be adjusted. The axle

adjustment is a labor-intensive operation requiring specic skills

and instrument, that is why we recommend to conduct axle adjust-

ments only at a service station.

During inspection of the steering knuckles, check the service-

ability of adjusting bolts 1 (Fig. 9.16) and steering stop bolts 3.

The value of steering angle B of the right wheel to the right,

Fig. 9.15. The front axle:

1 — ller plug; 2 — drain plug; 3 — safety valve; 4 — lower pin nut.

Loading...

Loading...