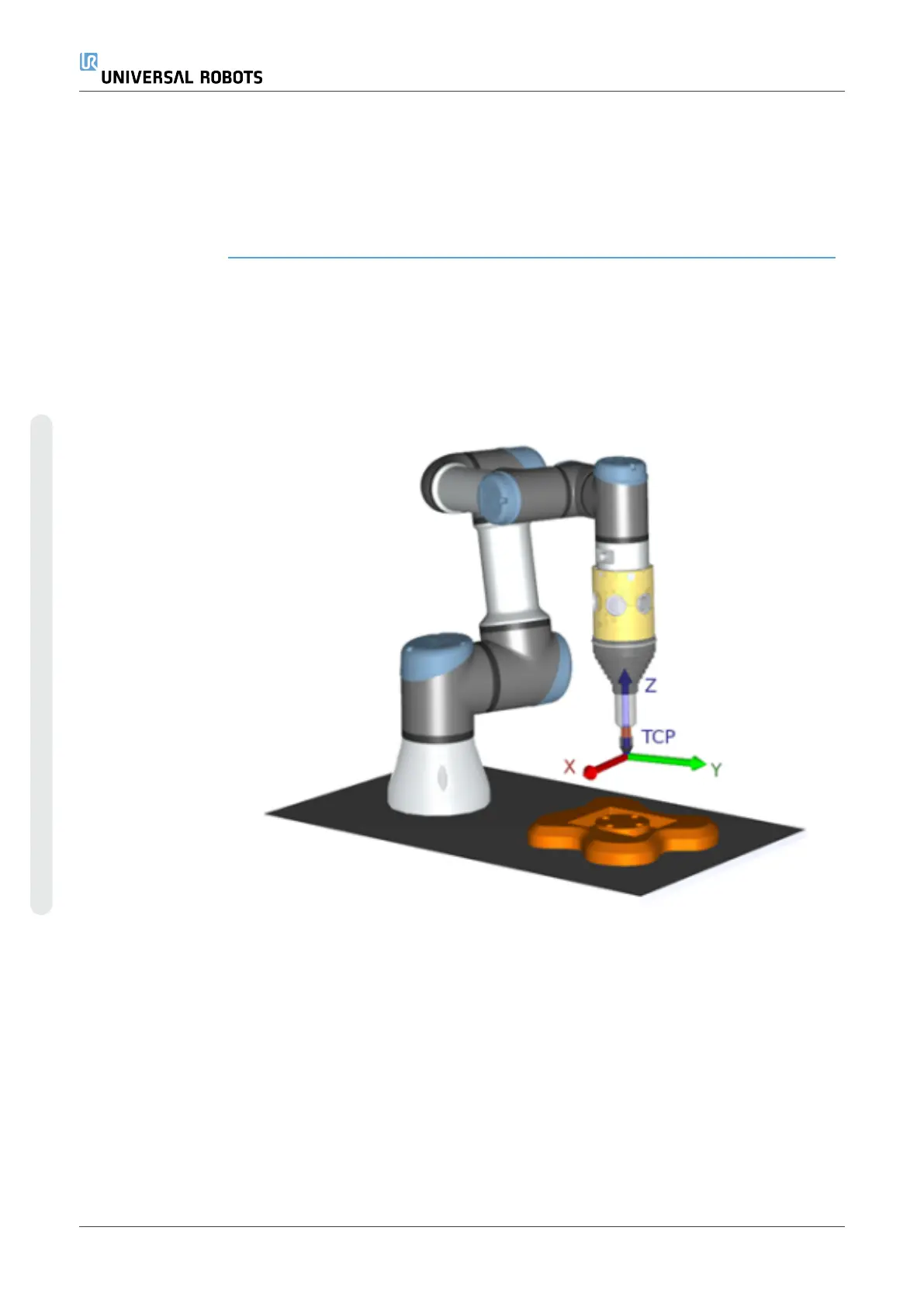

Regular TCP

Toolpath Moves

Similar to configuring a Remote TCP Toolpath Move, a regular TCP Toolpath Move

requires the following:

•

Toolpath file

•

Regular TCP

•

Plane Feature as a PCS

Configuring and

Importing a

Toolpath File

This is similar to configuring a Toolpath (see Configuring a Toolpath using CAD/CAM

Softwareon page272) and importing Toolpath (see Importing a G-code Toolpath into

PolyScopeon page272).

Configuring a

Regular TCP

•

Follow the instructions to configure a Regular TCP.

•

Verify the positive Z-axis of the tool points away from the part surface.

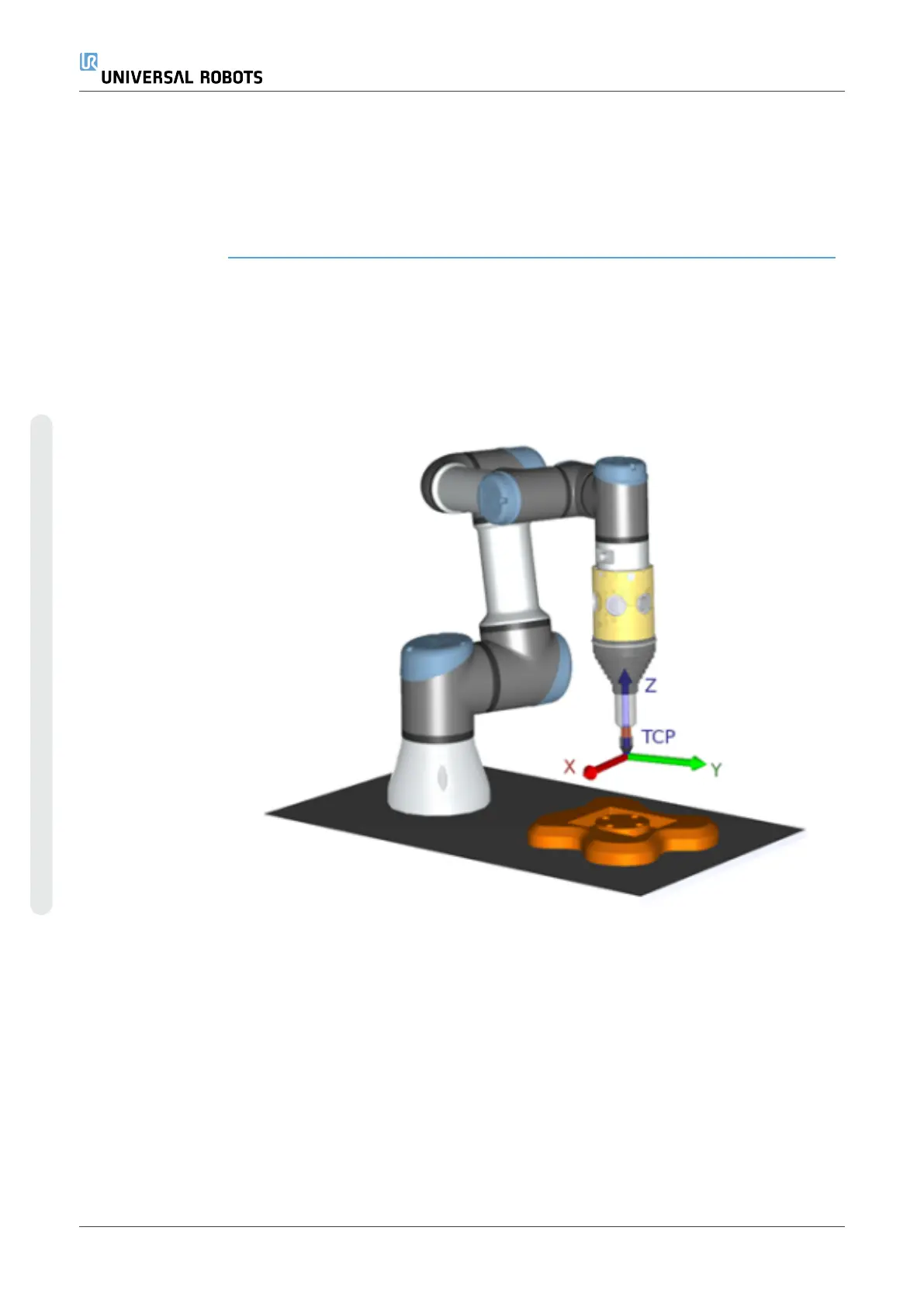

Configuring a

Plane Feature

PCS

1. Create a plane feature by Adding a plane or Teaching a plane. See .

2. Fix the part relative to the robot base.

3. Verify the correct TCP is us to create the plane feature. For high accuracy,

temporarily set up a sharp Remote TCP to complete this teaching process.

4. Jog the robot for the Remote TCP to touch the origin, positive X-axis and the

positive Y-axis direction of the PCS on the part.

5. Finish the teaching process and confirm the PCS position and orientation.

UR10e 276 User Manual

Copyright © 2009–2024 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...