Continuous Pulse

Alternates between high and low Running

(pause or stop

the program to

maintain the

pulse state)

Program

Termination

Cause

NOTICE

A program is terminated unscheduled if any of the following occur:

•

Robot stop

•

Fault

•

Violation

•

Runtime exception

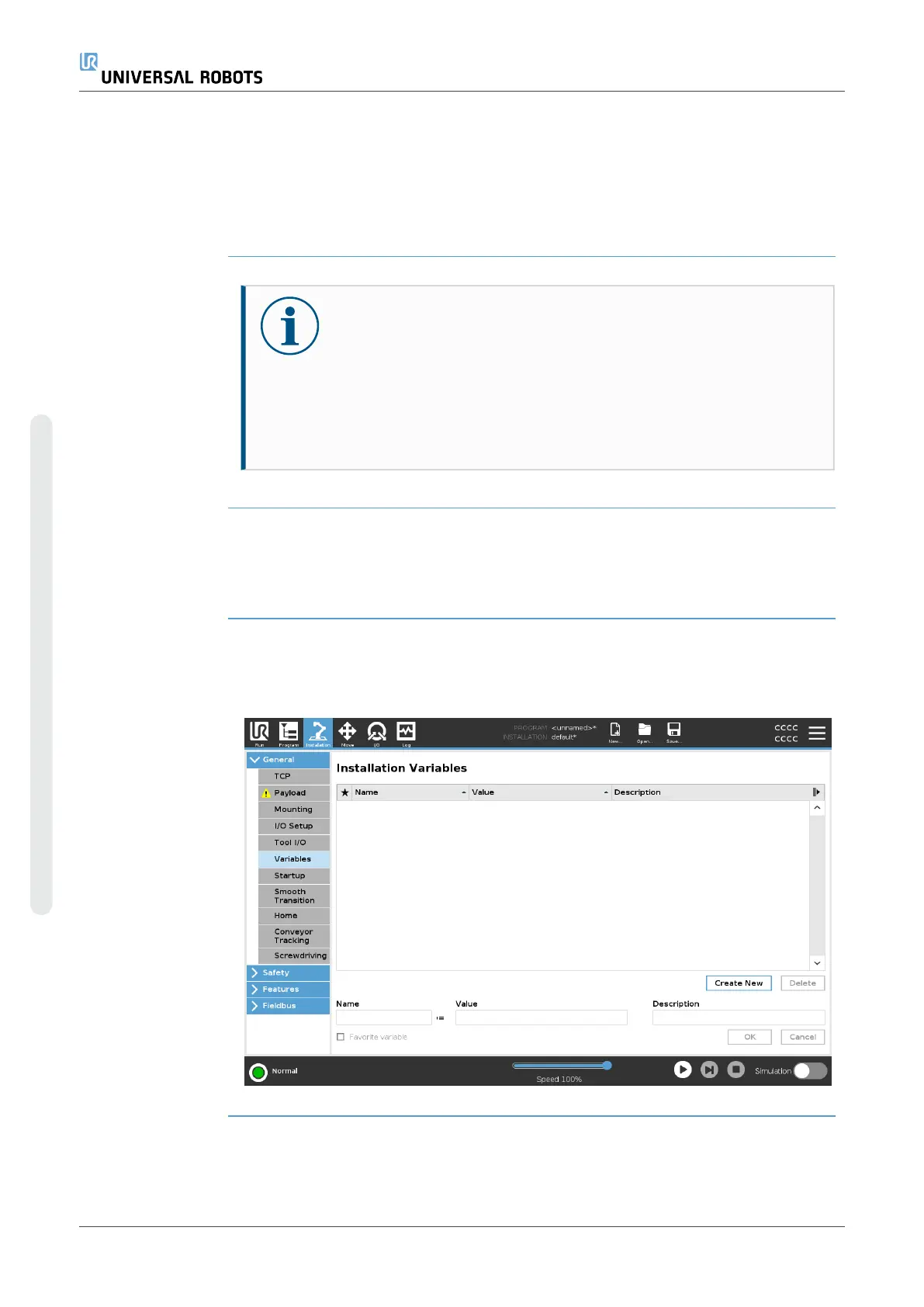

20.5. Installation Variables

Description Variables created on the Installation Variables pane are called installation variables

and are used like normal program variables. Installation variables are distinct because

they keep their value even if a program stops then starts again, and when the robot

arm and/or Control Box is powered down and powered up again.

UR10e 288 User Manual

Copyright © 2009–2024 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...