3.3. Securing the Robot Arm

Description

120

10

8 FG8

+

+

0.030

0.008

8.5 min.

8 FG8

+

+

0.024

0.006

x 13

8.5 min.

4 x

8.4

170

45°

S

2x 5

±1

Surface on which the robot is fitted

0.05

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

A3

UL class

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF UNIVERSAL

ROBOTS. ANY REPRODUCTION IN PART OR AS A

WHOLE WITHOUT THE WRITTEN PERMISSION OF

UNIVERSAL ROBOTS IS PROHIBITED

REV.

TEL: +45 89 93 89 89 FAX: +45 38 79 89 89 WEB: universal-robots.com

APP.

Engineer:

SIZE

SHEET 1 OF 1

SCALE:1:2

DWG NO.

TITLE:

DATE

NAME

Revision History:

731470

EN AW-6082 T6

1470.15 g

2014-06-16

Flange Base UR10 G5

UNLESS OTHERWISE SPECIFIED:

Dimensions are in millimeters

RoHS compliant (PB free)

Cleaned for chips and oil

NAME

DATE

Drawing

Approved

TOLERANCE

SURFACE FINISH

TREATMENT

MATERIAL

WEIGHT

PROJECTION:

DATE

2014-06-16

+/- 0,1 mm +/- 0,5°

Ra 1,6

Anodized nature 10-20µ

jmi

Status change date:

Replace drawing:

-0,1

+0,3

-0,3

2.2:

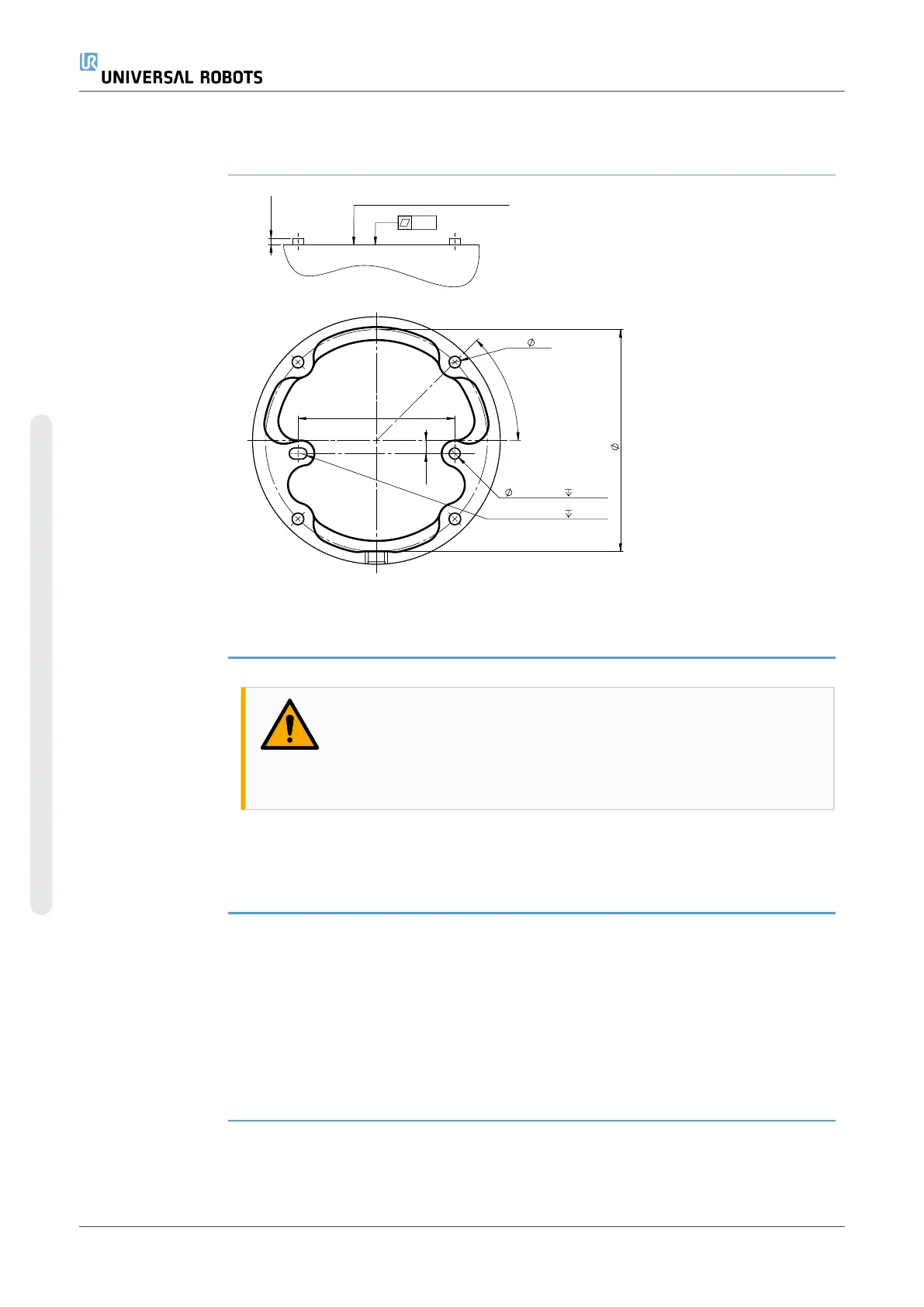

Dimensions and hole pattern for mounting the

robot.

To power down

the robot arm

WARNING

Unexpected start-up and/or movement can lead to injury

•

Power down the robot arm to prevent unexpected start-up

during mounting and dismounting.

1. Press the power button on the Teach Pendant to turn off the robot.

2. Unplug the mains cable / power cord from the wall socket.

3. Allow 30 seconds for the robot to discharge any stored energy.

To secure the

robot arm

1. Place the robot arm on the surface on which it is to be

mounted. The surface must be even and clean.

2. Tighten the four 8.8 strength, M8 bolts to a torque of 20 Nm.

(Torque values have been updated SW 5.18. Earlier printed

version will show different values)

3. If accurate re-mounting of the robot is required, use the Ø8

mm. hole and Ø8x13 mm. slot with corresponding ISO 2338

Ø8 h6 positioning pins in the mounting plate.

UR10e PolyScope X 42 User Manual

3.Mechanical Interface

Copyright © 2009–2024 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...