Editing a Line The line appears as two points in your program tree. You must define each point.

1. In Installation, tap Features.

2. Under Feature, select Line to add a line to your program tree.

3. The line is made up of two points:

•

Tap one point to edit those coordinates, then tap the other line point to

edit those coordinates.

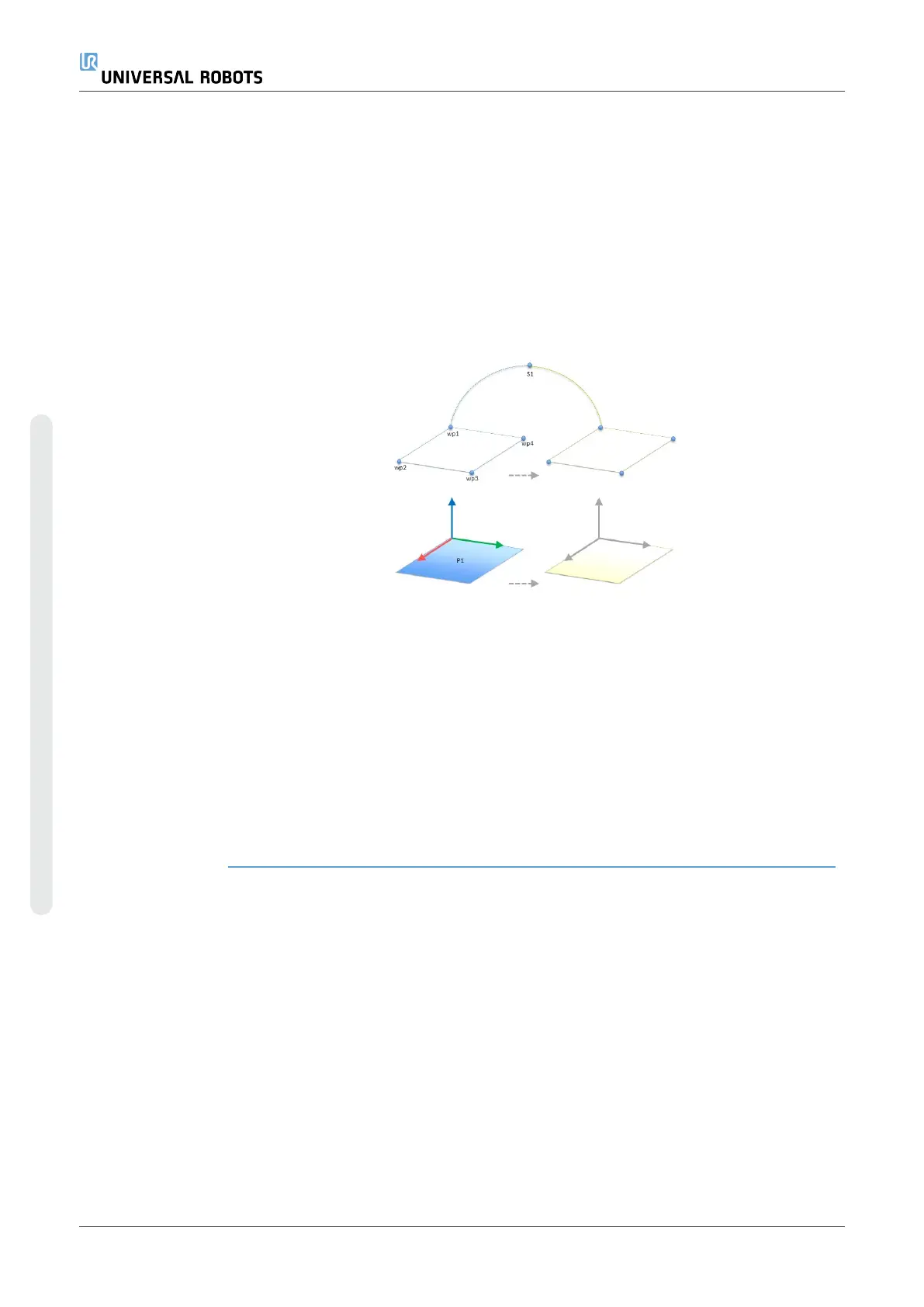

Editing a Plane

1. In Installation, tap Features.

2. Under Feature, select Plane to add a plane to your program tree.

3. Tap Edit to access the Edit screen to make changes to the positon and rotation

of the plane

20.14. Fieldbus

Description Here you can set the family of industrial computer network protocols used for real-time

distributed control accepted by PolyScope: MODBUS, Ethernet/IP and PROFINET.

20.14.1. MODBUS Client I/O Setup

Description Here, the MODBUS client (master) signals can be set up. Connections to MODBUS

servers (or slaves) on specified IP addresses can be created with input/output signals

(registers or digital). Each signal has a unique name so it can be used in programs.

Refresh Push this button to refresh all MODBUS connections. Refreshing disconnects all

modbus units, and connects them back again. All statistics are cleared.

Add unit Push this button to add a new MODBUS unit.

UR3e 304 User Manual

Copyright © 2009–2024 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...