Section 2 - Service and Repair Hydraulic Manifolds

067448-023 LX31/LX41 Electric and Bi-Energy Work Platform | European Specifications Page 2-17

2-7 H

YDRAULIC

M

ANIFOLDS

Though it is not necessary to remove the manifold to perform all maintenance procedures, a determination

should be made prior to beginning as to whether or not the manifold should be removed before mainte-

nance procedures begin. Refer to the General Information Section for remove and replace instructions.

M

AIN

H

YDRAULIC

M

ANIFOLD

Refer to “Setting Hydraulic Pressures” on page 2-11 for adjustment instructions.

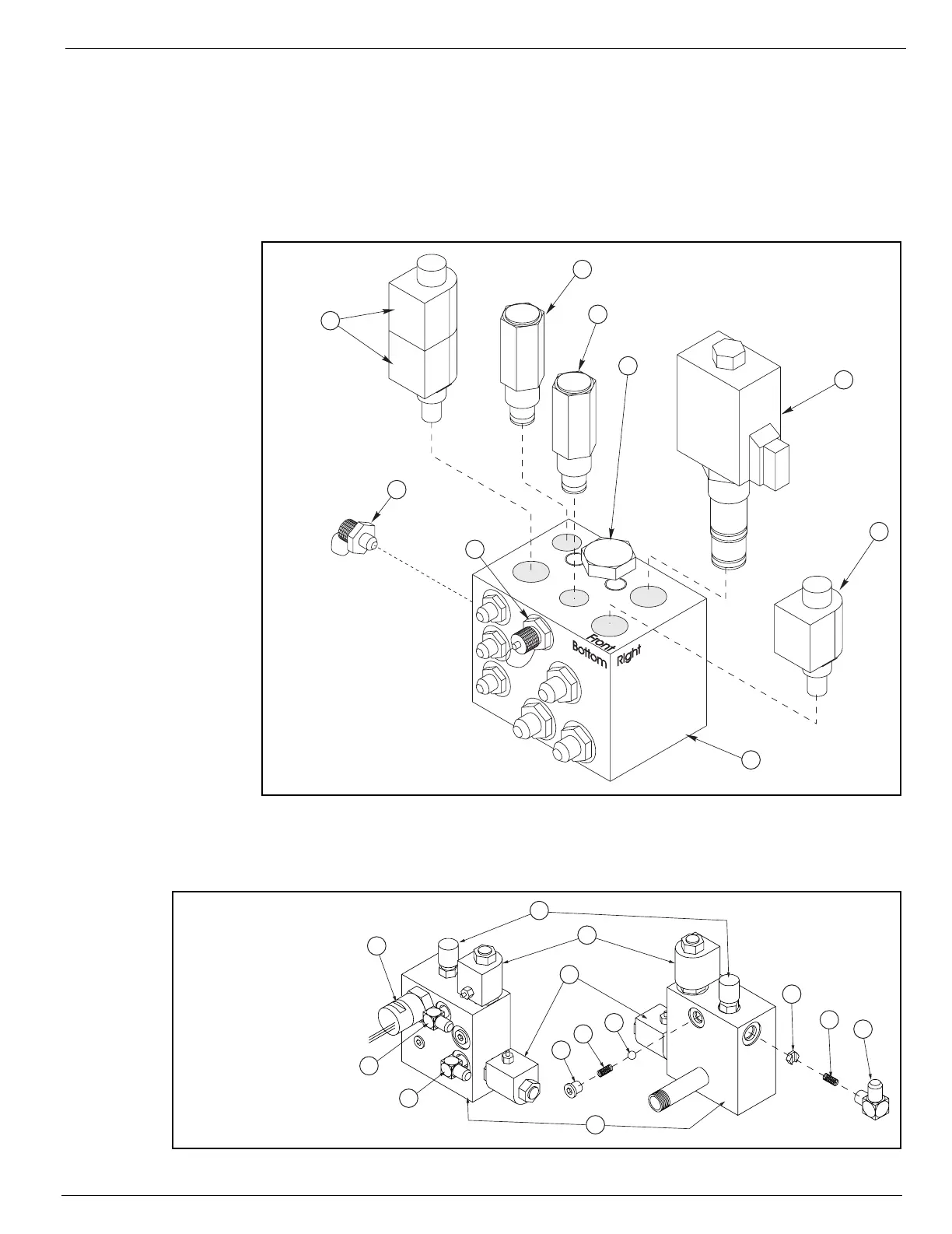

Figure 2-12:

Hydraulic Manifold

B

RAKE

H

YDRAULIC

M

ANIFOLD

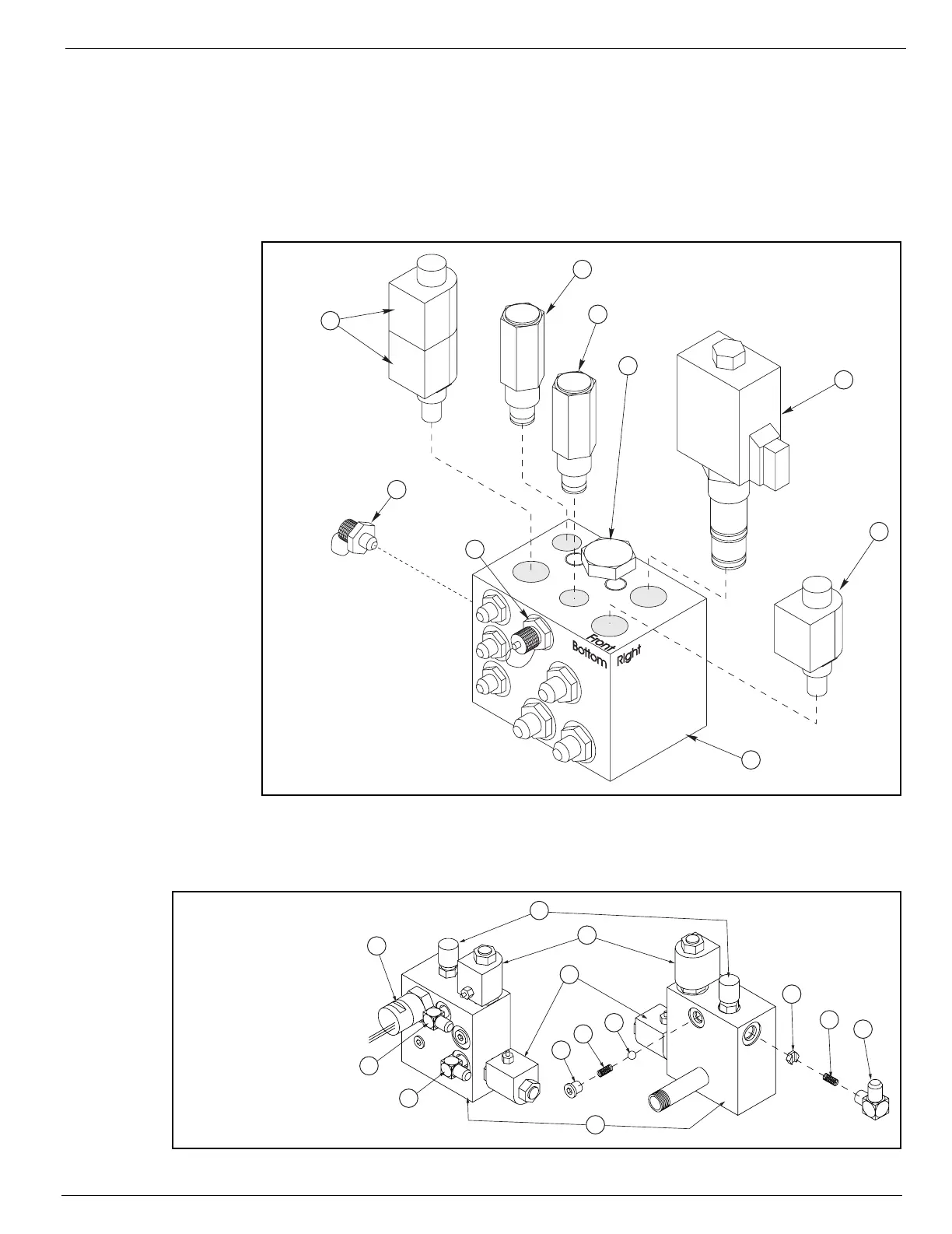

Figure 2-13:

Brake Hydraulic Manifold

7

6

5

4

3

2

8

9

1

1 Valve Manifold

2. High Pressure Test Port

3. Lift Test Port

4. Flow Control Valve

5. Lift Relief Valve

6. Steering Relief Valve

7. Steering Solenoids

8. Lift Solenoid

9. Dump Valve

4

2

3

6

7

8

11

10

9

5

12

13

1

1 Valve Manifold

2. Gage Port

3. Valve, Normally Open

4. Valve, Normally Closed

5. Pressure Switch

6. Steel Ball

7. Spring, 6,4 mm

(0.25 in.) Diameter

8. Plug

9. Orifice

10. Spring, 9,5 mm

(0.375 in.) Diameter

11. 90° Fitting, 6MB-6MJ

12. 90° Fitting, 4MB-6MJ

13. 90° Fitting, 4MB-4MJ

Loading...

Loading...