X-Series Work Platform 4-17

Maintenance

Section

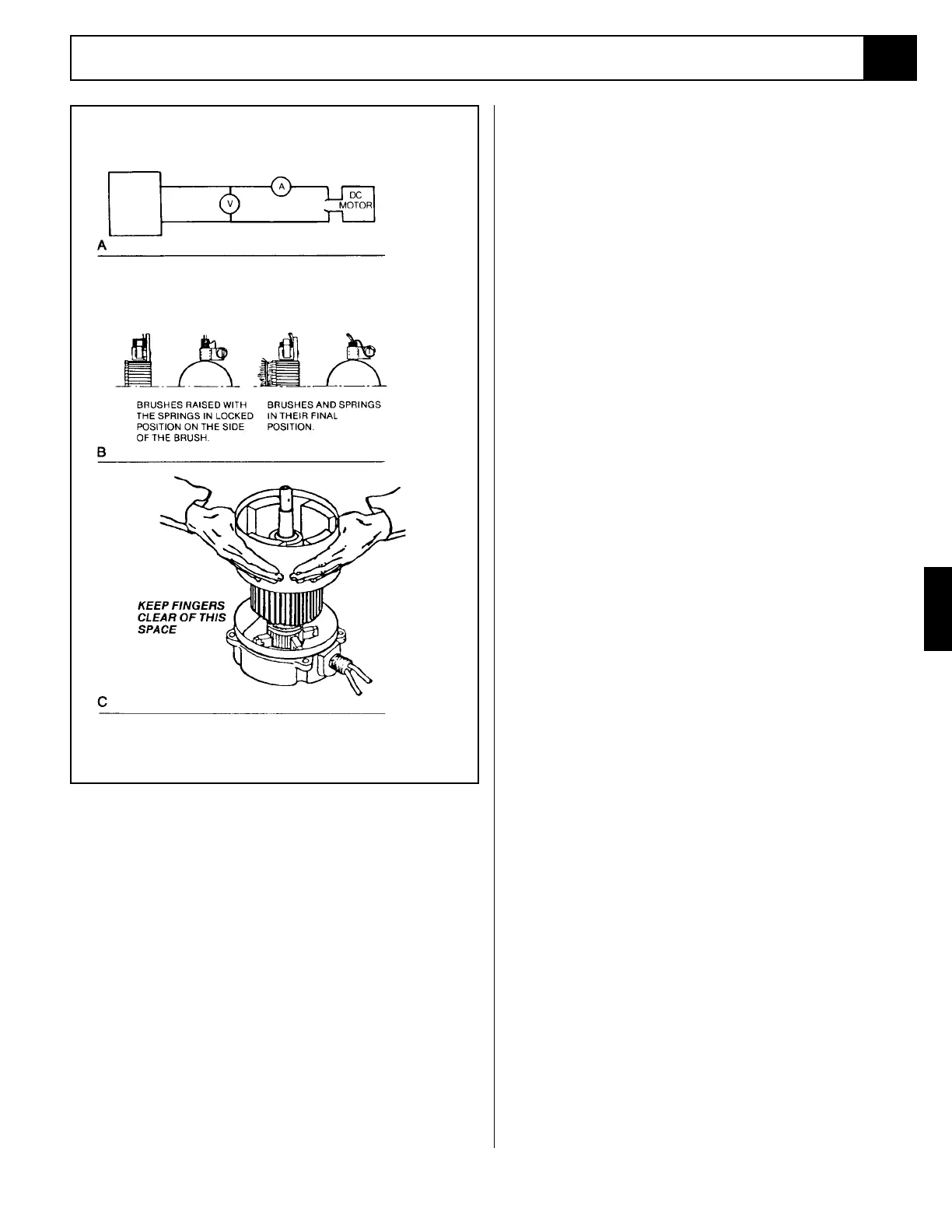

Figure 4-18: Electric Motor Service

DC

POWER

SUPPLY

AMMETER

VOLTMETER

4.13

NOTE: Observe how brushes are assembled in brush

holders and position of brush lead. New brushes

must be installed in same manner. Brushes should be

removed as follows:

•Remove brush spring clip from its mounting on

brush assembly.

•Lift brush assembly from brush holder.

•Disconnect brush assembly lead.

•New brush assembly to be installed by reversing

above procedure.

4. Inspect wire harness and all connections for signs of

damage due to overheating.

5. Check stator to see it is securely mounted.

REASSEMBLY

1. Install new brushes and be sure they are free in the

holder. Install brush with the lead wires positioned

as when received. Raise all brushes to the locked

position. (See Figure 4-18B and step 3 in the Inspec-

tion section).

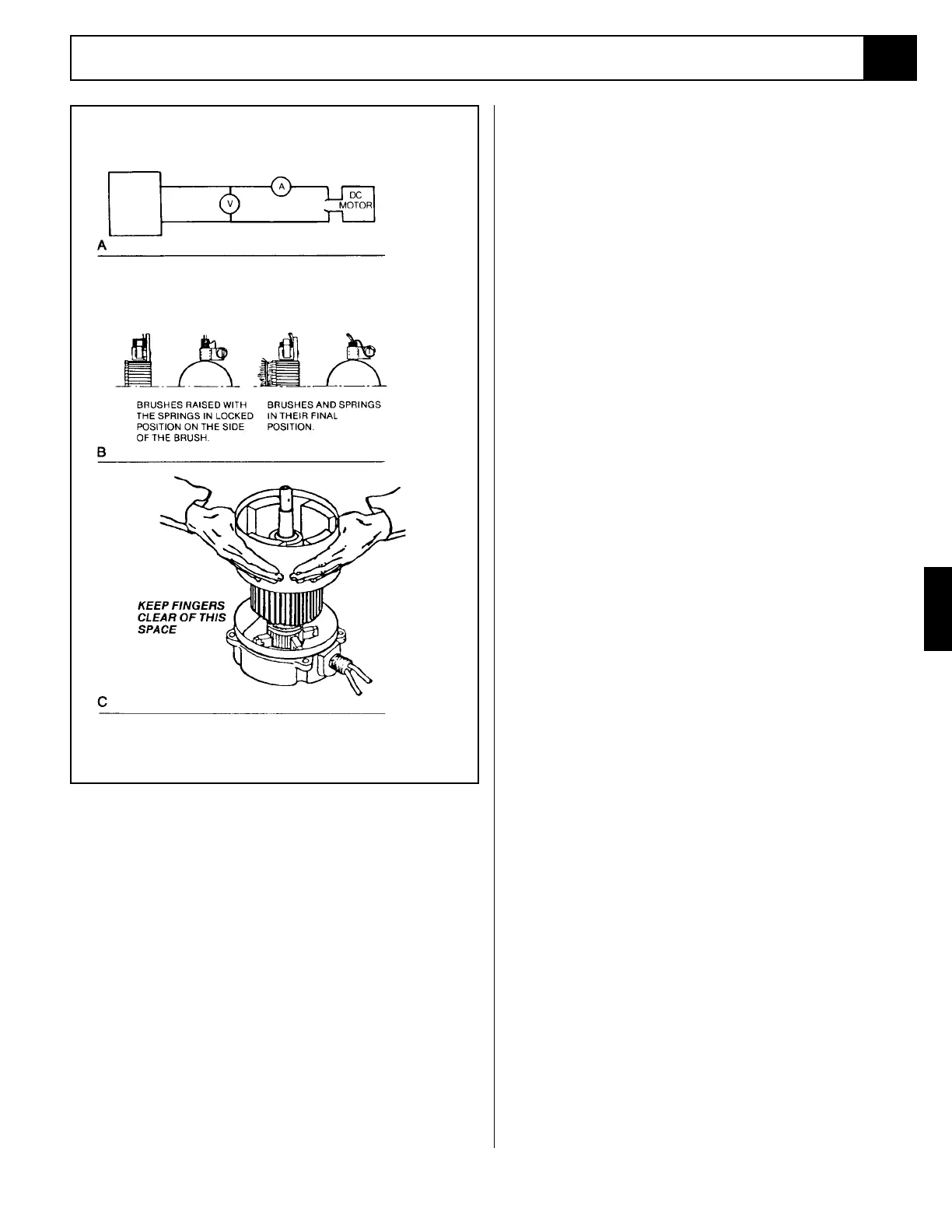

2. Place commutator cover on a work bench with

brush assembly facing upward.

3. Place the bearing spring into the bearing bore.

4. Take a complete armature assembly, including

bearings, and insert commutator end bearing into

the bearing bore.

Note: Do not reuse bearings which have been re-

moved from armature shaft. Keep assembly in a

vertical position. Use extreme care not to damage

armature with bearing pullers. New bearings should

be installed by pressing inner race of bearing onto

proper position on armature shaft.

5. Set the brushes to final position as shown in Figure

4-18B.

6. Place the complete stator down over the vertical

armature, and into position on the commutator

cover.

7. The stator assembly must be placed in a definite

relationship with the commutator covers in order to

obtain a neutral brush setting. There is a match-

mark on both items. These two marks must line up

exactly. Rotate until they do.

8. Assemble the pulley end cover in the proper rela-

tionship. Insert mounting bolts and tighten alter-

nately to ensure a good mechanical alignment.

9. Spin the shaft by hand to see if it is free. Be sure

motor leads (if used) are not touching together. If

the leads are touching, a generator action will give

the effect of friction in the motor. A no-load test can

now be performed. At rated voltage, observe the

no-load current. It should be less than 20% of the

nameplate full load current. Anything higher indi-

cates:

•Brushes are not on neutral setting (check match-

marks for exact alignment).

•Faulty armature.

Loading...

Loading...