4-6 X-Series Work Platform

Maintenance

Section

4.5

Reservoir Breather/Cap

Clean breather/cap, when filter is replaced, with clean-

ing solvent and blow dry with clean dry compressed air.

7. Release the Chassis Lift Switch. Tighten locknut or

replace Main Relief Valve cover and torque to 6 Ft/

Lbs (8 Nm.).

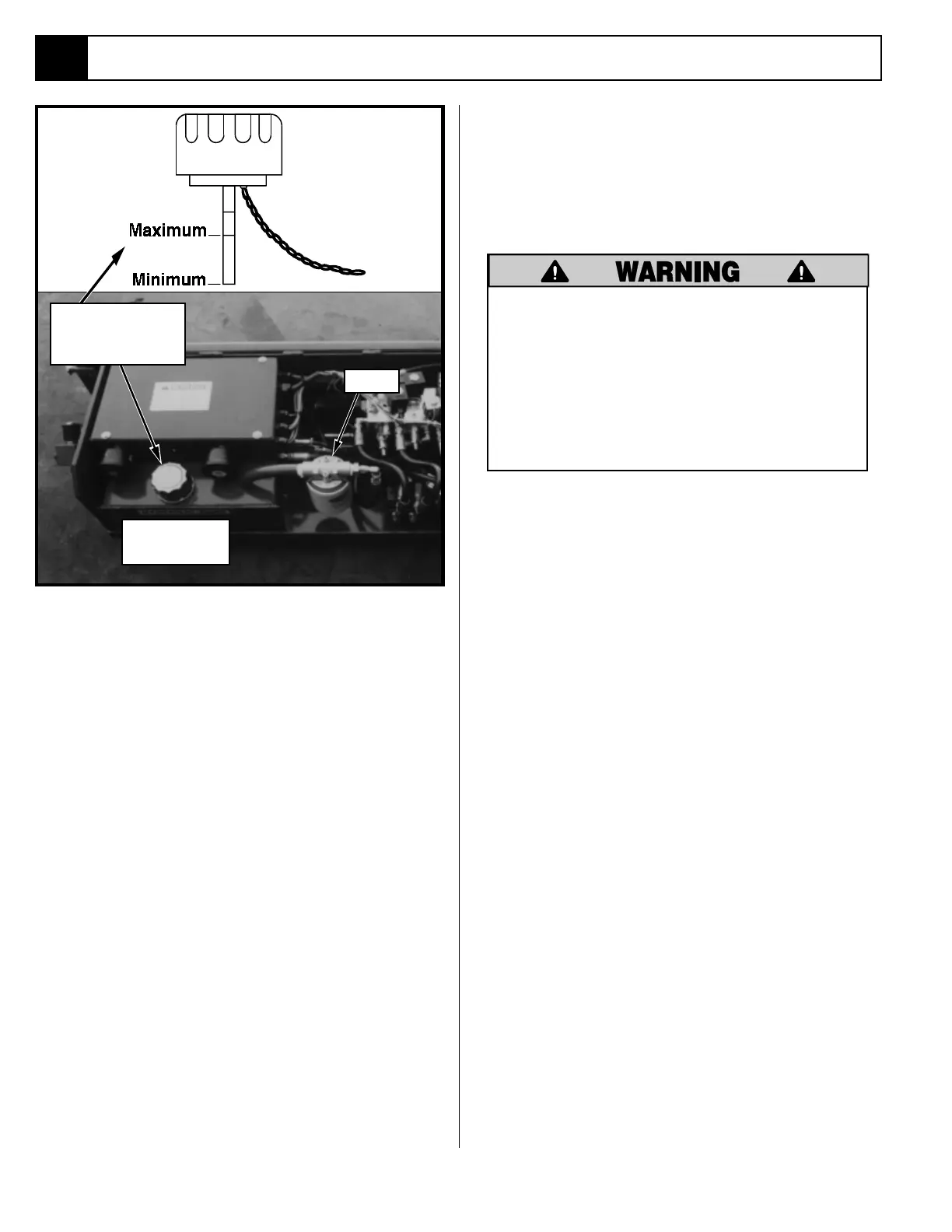

Figure 4-5: Hydraulic Oil Tank and Filter

Drain Plug

(Under Tank)

4.5 Setting Hydraulic Pressures

(Figure 4-5)

Check the hydraulic pressures whenever the pump,

manifold or relief valves have been serviced or

replaced.

The hydraulic oil may be of sufficient

temperature to cause burns. Wear safety

gloves and safety glasses when handling

hot oil.

The oil in the hydraulic system is under

very high pressure which can easily cause

severe cuts. Obtain medical assistance

immediately if cut by hydraulic oil.

MAIN RELIEF VALVE (Figure 4-5)

1. Operate the hydraulic system 10-15 minutes to

warm the oil.

2. Remove high pressure gauge port cap and install the

pressure gauge assembly.

3. Loosen locknut or remove cover on the Main Relief

Valve and turn adjusting screw counterclockwise

two full turns.

4. Place the maximum rated load, see

Table 1-1

, on

the platform.

5. Turn the Chassis Key Switch to CHASSIS. Position

the Chassis Lift Switch to UP position and hold it

there.

6. Slowly turn the Main Relief Valve adjusting screw

clockwise to increase the pressure until the platform

just begins to raise. Check the gauge and verify the

pressure does not exceed 2400 psi (165 bar). If it

does readjust the Main Relief Valve to 2400 psi (165

bar) maximum.

Hydraulic Tank

Breather/Cap/

Dipstick

Filter

Loading...

Loading...