X-Series Work Platform 4-13

Maintenance

Section

4.10

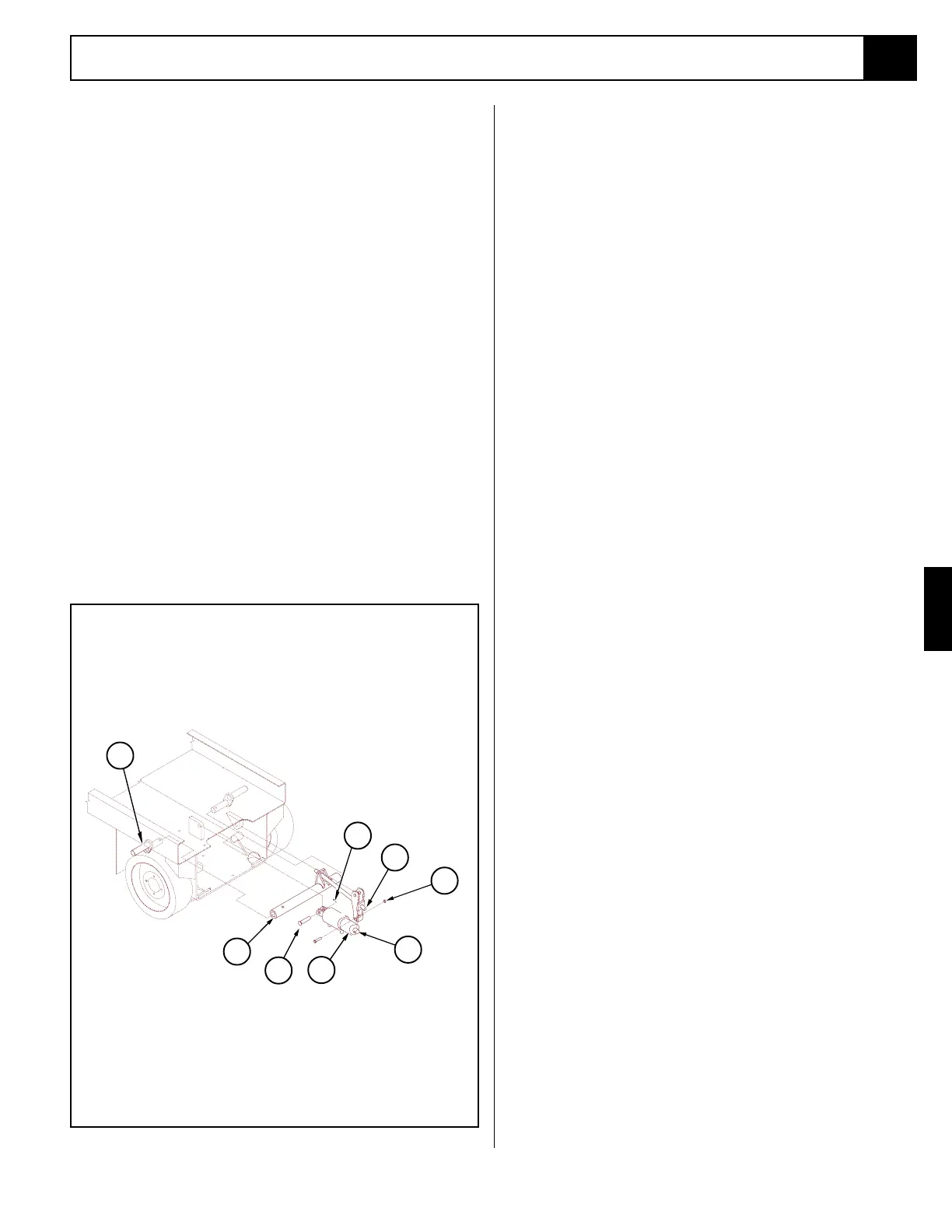

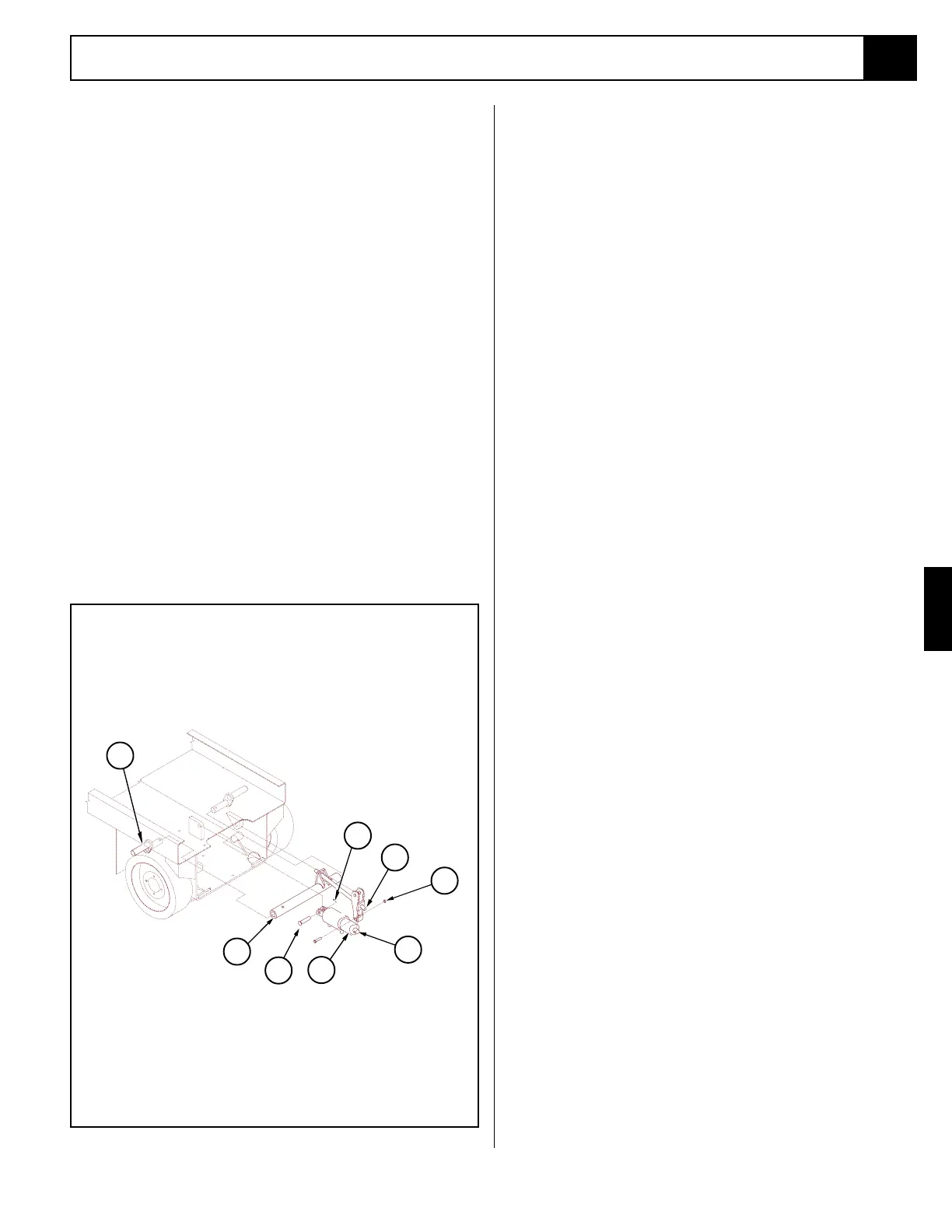

Figure 4-14: Brake Cylinder Installation

1. Brake Cylinder

2. Rod End Shoulder Bolt

3. Locknut

4. Brake Tube (shown

removed for clarity only)

5. Clevis End Pivot Pin

6. Adjustment Locknut

7. Left Brake Shoe

8. Cotter Pin

3. Remove the plugs from the hose assemblies and

connect to the drive motor.

5. Install the wheel and secure with wheel bolts,

torque to 80 Ft/Lbs (108 Nm).

6. Remove blocks, lower the jack and remove. Oper-

ate the drive system and check for leaks.

4.10 Brake Cylinder

(Figure 4-14)

The brake cylinder is located between the rear wheels

at the rear of the chassis.

REMOVAL

1. Block the wheels to prevent the work platform from

rolling when the brake is removed.

2. Remove the adjustment locknut and jam nut.

3. Tag and disconnect the hose assemblies and cap the

openings to prevent foreign material from entering.

6. Remove the shoulder bolt and locknut that mounts

the cylinder rod to the brake tube.

7. Remove the cotter pin and pivot pin from the rear

cylinder mount. Remove the cylinder.

DISASSEMBLY

1. Remove the set screw from the outside barrel

assembly and unscrew the cylinder.

2. Completely disassemble the cylinder including

removing the piston nut and piston.

3. Remove all the seals and o-rings noting their loca-

tion to aid in reassembly.

CLEANING AND INSPECTION

1. Wash all the metal parts in cleaning solvent and

blow dry with filtered compressed air.

2. Inspect all the threaded components for stripped or

damaged threads.

3. Check the inside surface of the cylinder barrel for

scoring or excessive wear.

4. Check the piston and headcap for scoring or exces-

sive wear.

5. Inspect the surface of the shaft for scoring or exces-

sive wear.

ASSEMBLY

1. Lubricate and install new seals and o-rings.

2. Install the headcap onto the shaft.

3. Install the new internal backup rings and o-rings on

the piston.

4. Install the piston on the shaft and secure with the

piston nut, torque to 250 Ft/Lbs (339 Nm).

5. Lubricate the piston seal with clean hydraulic fluid

and install the shaft assembly in the inner cylinder

barrel.

6. Install the spring and screw the cylinder barrels

together until tight and the ports are in-line.

7. Install the set screw.

INSTALLATION

1. Install the clevis end pivot pin through the cylinder

clevis and cylinder link and secure with a

new cotter

pin.

2. Install the rod end shoulder bolt through the cylin-

der rod and brake tube mounting tabs and secure

with the locknut.

3. Install the hydraulic hoses.

4. Install the adjustment locknut. Tighten the bolt until

the brake shoes fully engage the tires, secure with

the locknut.

5. Lower the machine and operate the drive circuit

and check that the brake shoes retract and clear the

tires when driving and fully engage the tires when

stopped. Check for leaks.

1

2

3

4

5

6

7

8

Loading...

Loading...