509

REVO-E Heat pump 5 Troubleshooting

5.6 Inspecting functionality of individual

components

The inspection of individual components may take the

form of a visual inspection or manual electric inspection.

In addition, electrical components can be inspected using

the DCT components test. A compilation of these can be

found in Table 503.

Details can be found in “OI REVO-E Diagnostics“ Chap.

3.5 Diagnosis Control Test.

1)

When switching off compressor, error F18 will be

marked for 1 min.

2)

Adjustment forces system into low pressure range

until shut off.

3)

Adjustment forces system into high pressure range

until shut off.

5.6.1 General visual inspection

– Inspect components for damage (cracks, deforma-

tion, seal, discoloration, etc.) and replace, as needed.

– Inspect plugs and lines for corrosion, (loss of) contact,

crimping errors, etc. and repair, as needed.

– Inspect plug contacts for corrosion and proper seat-

ing, repair as needed.

– Visually examine all electric lines (high and low volt-

age) for abrasion

5.7 Diagnosing the REVO-E units using

the Diagnosis Control Test – DCT

diagnostic software

Information about this can be found in the operating

instructions “OI REVO-E Diagnostics“, Chap. 4.

5.8 Diagnosing the frequency converter

Information about this can be found in the operating

instructions “OI REVO-E Diagnostics“, Chap, 5 / Attach-

ment EPA instructions for searching for errors.

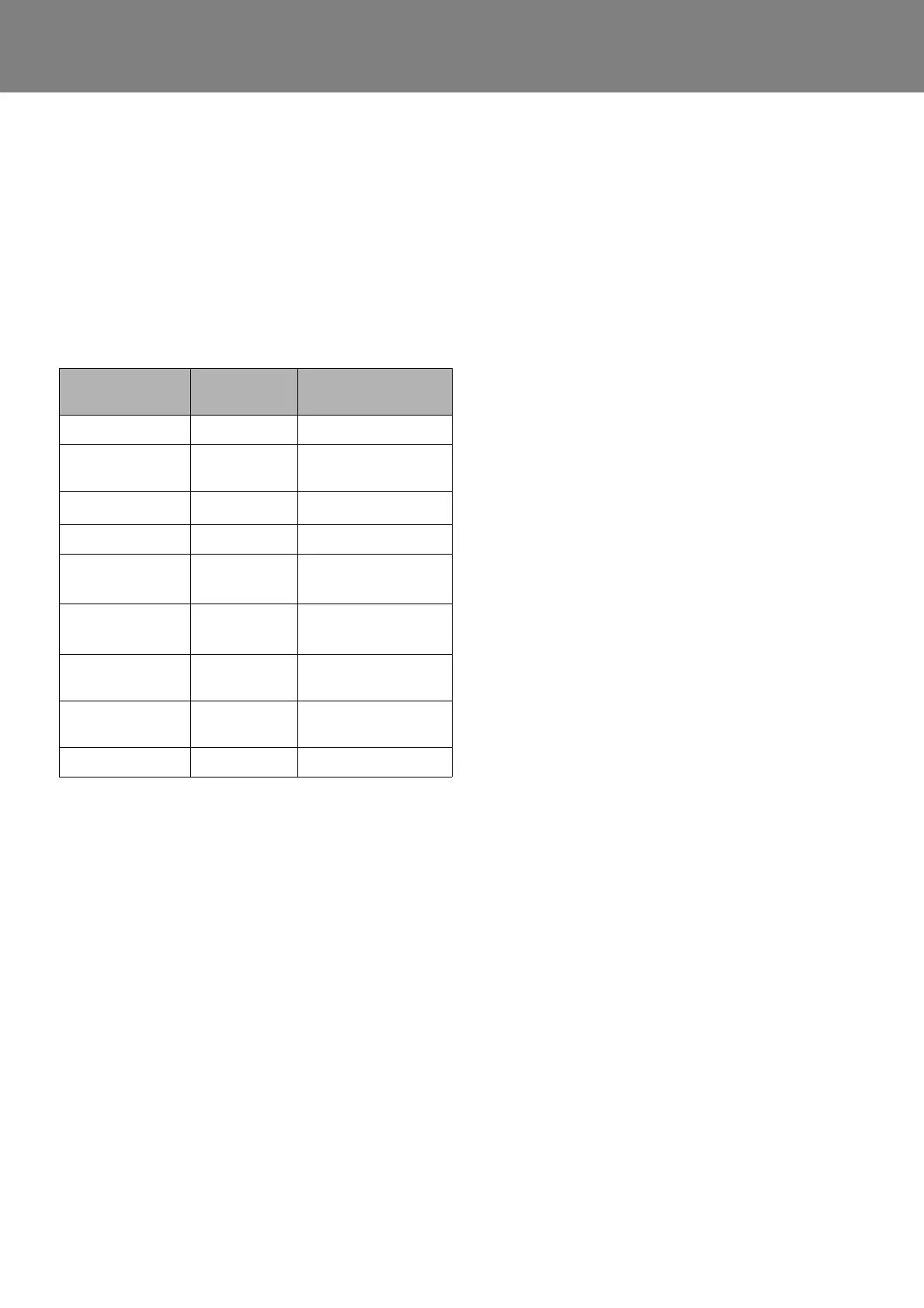

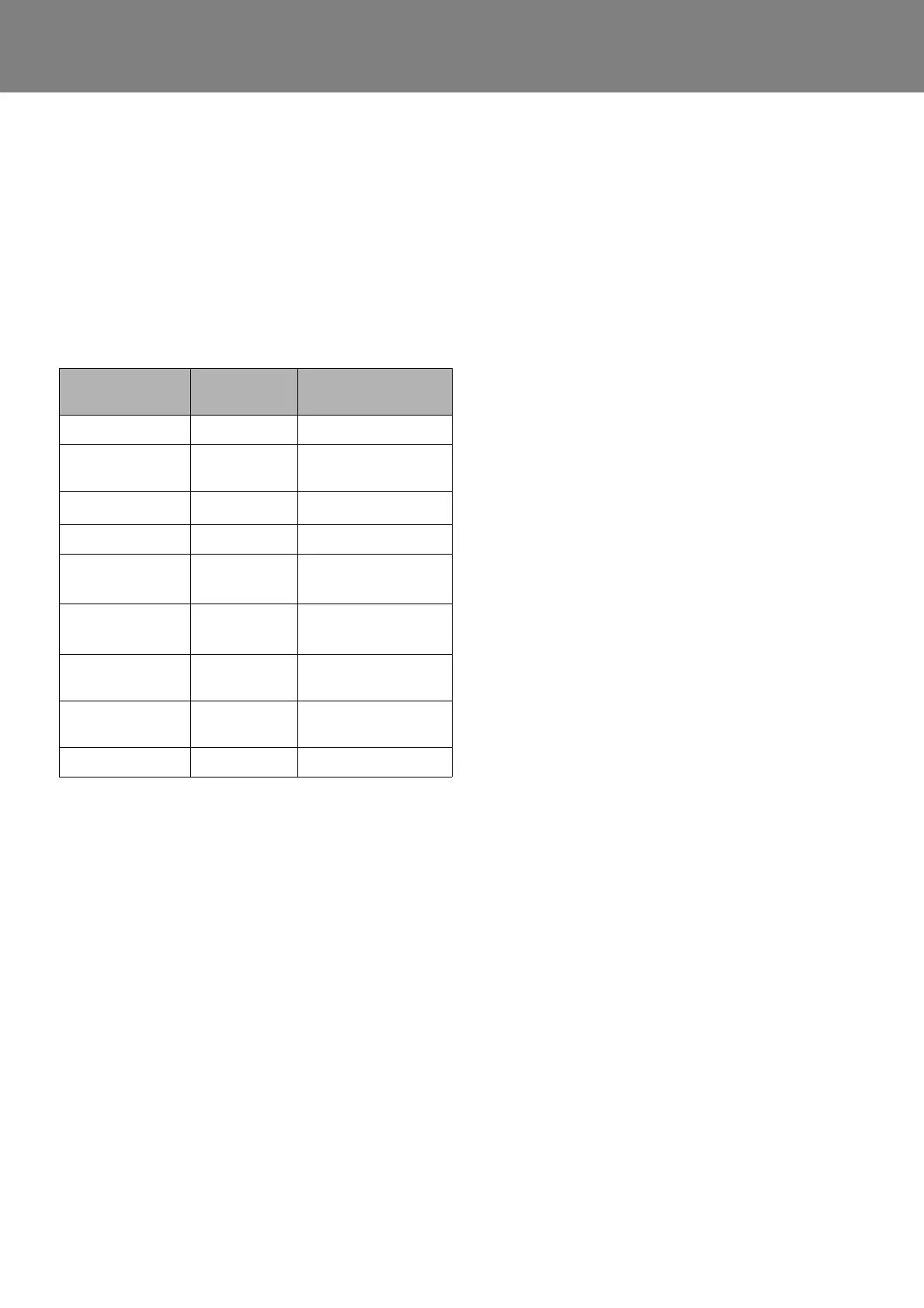

Table 503

Components

Measured

values

Measurement steps

Axial fans Speed 0%/ 50%/ 80%/ 100%

Double radial

blowers

Speed 0%/ 50%/ 80%/ 100%

Compressor

1)

Speed 32%/ 50%/ 100%

Solenoid valve Position Open / closed

Low pressure

switch

1), 2)

Position Switched off

High pressure

switch

1), 3)

Position Switched off

Position of air

valves

Position Fresh air / recirculat-

ing air

4-way reversing

valve

Position Heat Pump / Cooling

Valve de-icing Position Open / closed

Loading...

Loading...