702

REVO-E Heat pump 7 Maintenance

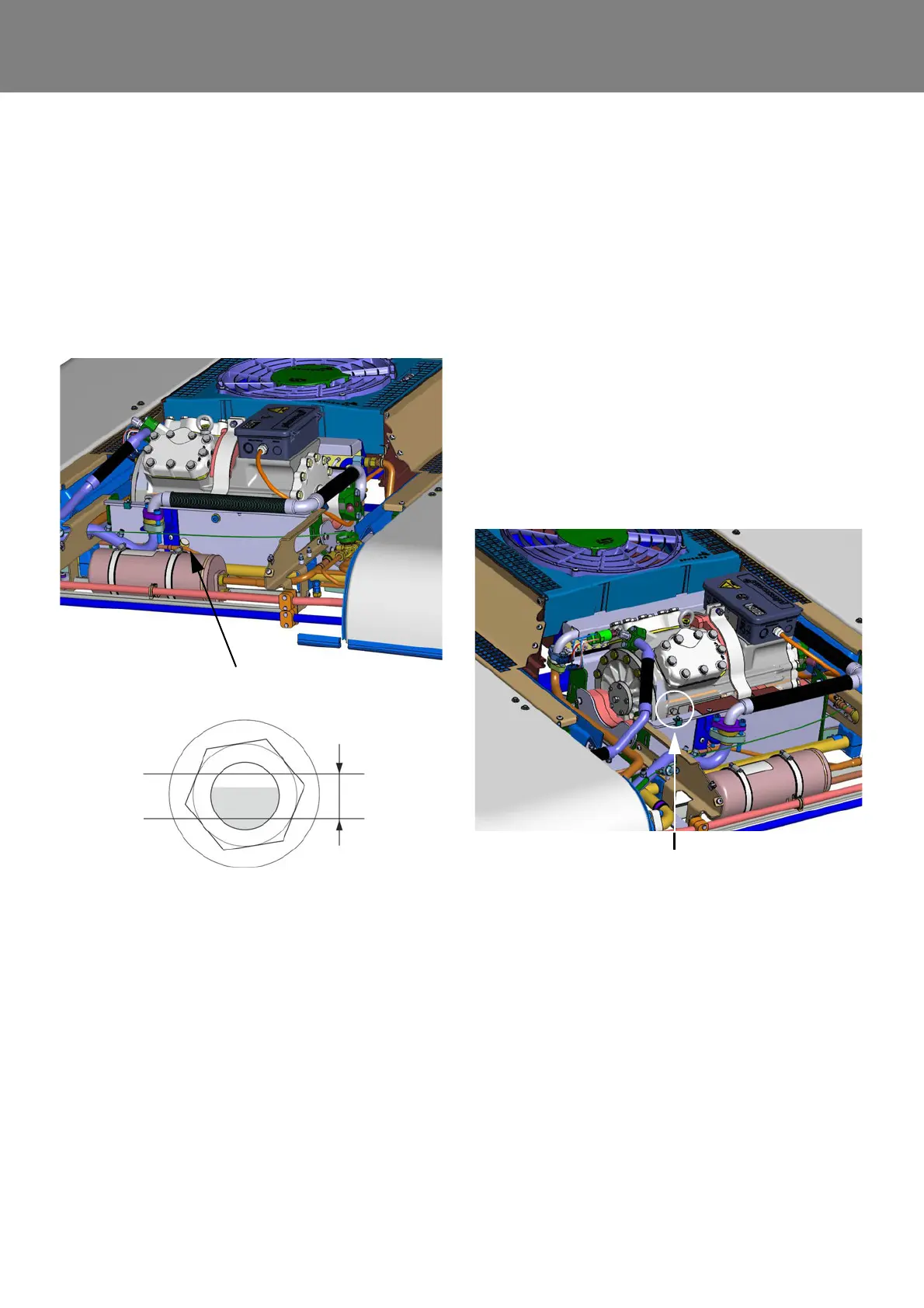

7.4.3 Inspecting the oil level of the compressor

Inspect the oil level after at least 10 minutes of running the

system.

Inspect the oil level by opening the rear side of the

compressor pan (Fig. 701).

The correct oil level is between the minimum and

maximum display Fig. 701. For deviations, see Chapter

7.4.4.

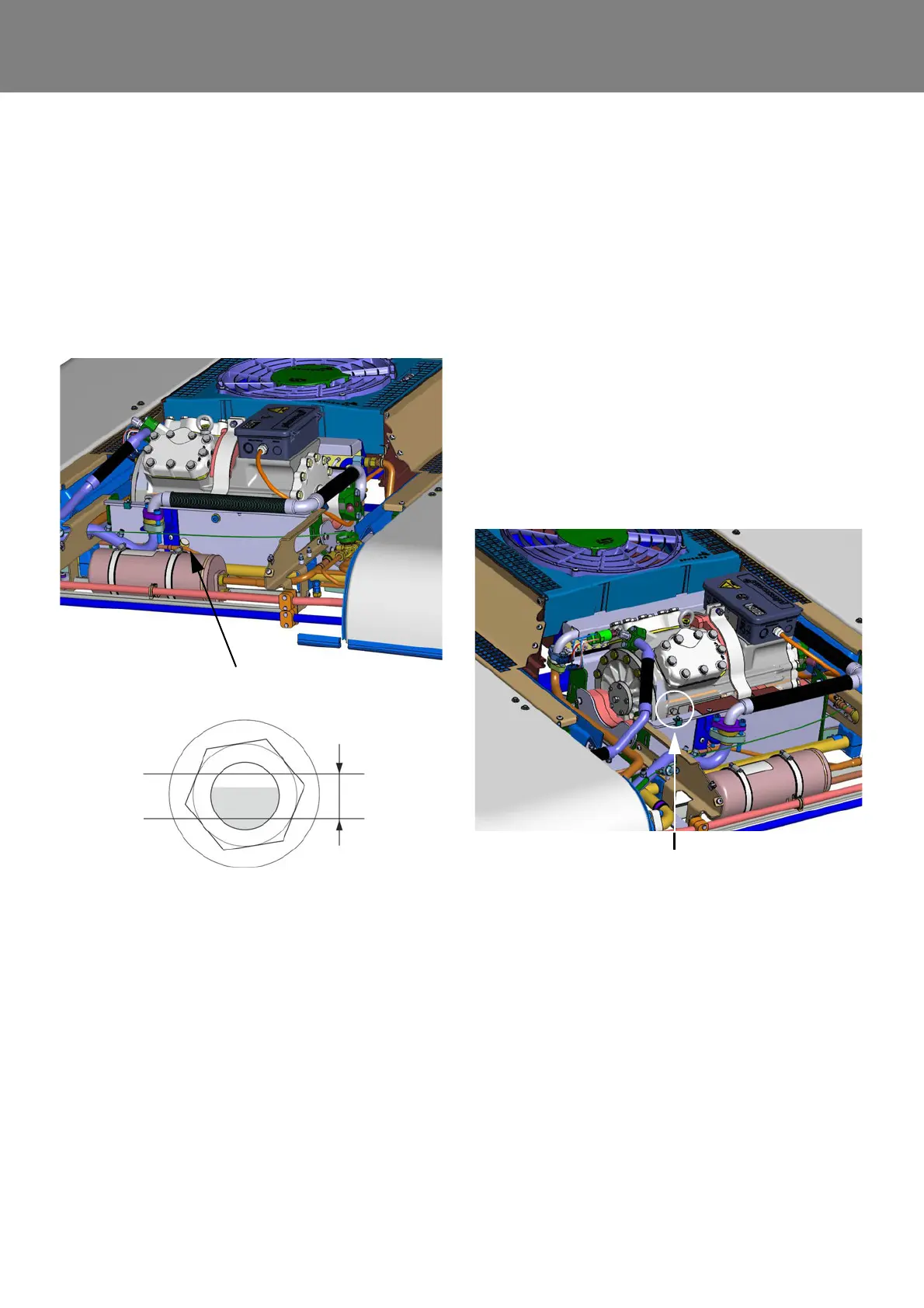

7.4.4 Changing the compressor oil

NOTE:

For this procedure, follow the preparation and follow-up

work described in 7.4.

Always change the compressor oil when conducting

servicing or repair work on the compressor.

Open the oil filling screw (Fig. 702), siphon out the old oil

and feed in the new oil.

The amount of oil to put in corresponds to the amount

taken out. The oil level, however, must be verified using

the sight glass after running the system for 10 min.

The following refrigerator oils are approved for use in the

compressor:

– Fuchs Reniso Triton SE55

– Fuchs SEZ 32

– ICI Emkarate RL 46 S

– Mobil Arctic AL46

– Shell Clavus R 46

Fig. 701 (exemplarily)

Oil level

max.

min.

ca. 0.8 l

Opening for sight glass

Sight glass

Fig. 702 (exemplarily)

Filling screw

Compressor oil

Loading...

Loading...